John Deere柴油機難啟動的原因為曲軸位置/凸輪位置傳感器不同步的維修技術資料約翰迪爾機油冷卻器RE59296

John Deere柴油機難啟動的原因為曲軸位置/凸輪位置傳感器不同步的維修技術資料約翰迪爾機油冷卻器RE59296

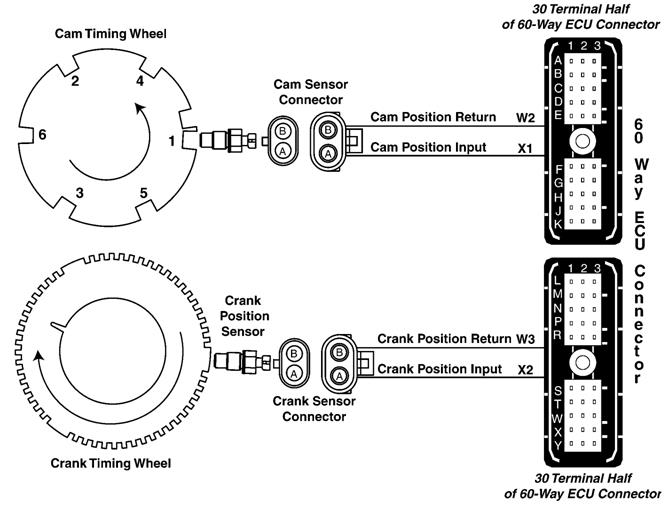

重要事項:不要將探頭強行插入接頭計算正確的噴射開始時間和噴射量

否則會導致端子損壞。使用燃油噴射,然后命令EUIs

JT07328連接器適配器測試套件。測量約翰迪爾位置傳感器信號的凸輪和曲軸位置傳感器接頭之間的已知關系。這將確保信號允許約翰迪爾ECU識別何時一個信號端子沒有損壞。與另一個不同步。

如果出現以下情況,將設置DTC SPN 637 FMI 7:

約翰迪爾凸輪軸和曲軸位置傳感器

•ECU檢測到凸輪和曲柄輸入

•約翰迪爾凸輪和曲柄位置傳感器均不同步。感應式拾波傳感器,用于檢測

凸輪和曲柄正時輪。如果設置了DTC SPN 637 FMI 7,ECU將使用

確定發動機轉速和發生的曲柄位置輸入:

相對于TDC的精確活塞位置。使用

凸輪位置輸入,ECU能夠確定•根據故障代碼的原因,氣缸在壓縮發動機末端時可能會死亡,然后可能會重新啟動,也可能不會重新啟動。(打、擊等的)一下根據此信息,ECU

IMPORTANT: Do not force probes into connector calculates the correct start of injection and amount

terminals or damage will result. Use of fuel to inject, then commands the EUIs

JT07328 Connector Adapter Test Kit accordingly. A known relationship between the cam to make measurements in position sensor signal and the crank position sensor connectors. This will ensure that signal allows the ECU to recognize when one signal terminal damage does not occur. is not in sync with the other.

DTC SPN 637 FMI 7 will set if:

Camshaft and Crankshaft Position Sensors

• The ECU detects that the cam and crank inputs are

• The cam and crank position sensors are both not in sync with each other. inductive type pickup sensors that detect notches on

the cam and crank timing wheels. The ECU uses the If DTC SPN 637 FMI 7 sets, the following will

crank position input to determine engine speed and occur:

precise piston position in relation to TDC. Using the

cam position input, the ECU is able to determine • Depending on the cause of the trouble code, the when a cylinder is at the end of the compression engine may die, and then it may or may not restart. stroke. Based on this information, the ECU

Level 6 ECU - DTC SPN 637 FMI 7 Crank Position/Cam Position Out of Sync Diagnostic Procedure

NOTE: Before using this diagnostic procedure, perform a preliminary inspection of the 60-way ECU connector and the cam and crank position sensors connectors looking for dirty, damaged, or poorly positioned terminals.

|

1 Intermittent Fault Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition ON, engine OFF 2. Using the DST, monitor DTCs on the active code display parameter 3. Make notes of any DTCs, then clear all DTCs 4. Ignition ON, engine running 5. Using the DST, monitor DTCs on the active code display parameter |

SPN 637 FMI 7 reoccurs: GO TO 2 SPN 637 FMI 7 doesn’t reoccur: Problem is intermittent. If no other codes are present, see INTERMITTENT FAULT DIAGNOSTICS, earlier in this Group. – – –1/1 |

|

2 Cam to Crank Timing Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Remove rocker arm cover NOTE: Rocker arm cover gasket is reusable if no visible damage is detected. Do not store cover resting on gasket surface. 3. Check cam to crank timing. See CHECK AND ADJUST CAMSHAFT-TO-CRANKSHAFT TIMING in CTM100, Section 02, Group 050. |

Crank timing pin engages in slot: GO TO 3 Crank timing pin won’t engage in slot: Adjust timing between cam and crank. See CHECK AND ADJUST CAMSHAFT-TO- CRANKSHAFT TIMING in CTM100, Section 02, Group 050. – – –1/1 |

|

3 Crank and Cam Timing Wheel and Sensor Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Remove cam and crank timing pins 3. Inspect crank timing wheel and cam timing wheel for broken teeth, nicks burrs, or other damage 4. Remove cam and crank sensors from cylinder head and timing gear cover 5. Inspect cam and crank position sensors for cracks, debris, or other damage. |

All components OK: GO TO 4 Faulty component found: Replace faulty component and retest. – – –1/1 |

|

4 Crankshaft Position Sensor Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Disconnect crank position sensor connector 3. Using a multimeter, measure resistance between both terminal of the crank position sensor |

Measurement between 2500 and 3500 ohms: GO TO 5 Measurement below 2500 ohms or above 3500 ohms: Faulty crankshaft position sensor – – –1/1 |

|

5 Camshaft Position Sensor Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Disconnect cam position sensor connector 3. Using a multimeter, measure resistance between both terminals of the cam position sensor |

Measurement between 2500 and 3500 ohms: GO TO 6 Measurement below 2500 ohms or above 3500 ohms: Faulty camshaft position sensor – – –1/1 |

|

6 Open in Crank Position Sensor Input and Return Wire Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Disconnect crank position sensor connector 3. Disconnect 60-way ECU connector 4. Using a multimeter, measure resistance between: · Terminal A of the crank position sensor harness connector and terminal X2 in the harness end of the 60-way ECU connector. · Terminal B of the crank position sensor harness connector and terminal W3 in the harness end of the 60-way ECU connector. |

Both measurements 5 ohms or less: GO TO 7 Either measurement greater than 5 ohms: Open in crank position sensor input wire OR Open in crank position sensor return wire OR Terminals A and B in the crank position sensor harness connector possibly inverted – – –1/1 |

|

7 Crank Position Sensor Input Wiring Harness Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Crank position sensor connector and 60-way ECU connector still disconnected 3. Using a multimeter measure resistance between terminal X2 in the harness end of the 60-way ECU connector and: · A good ground · All other terminals in both ECU connectors |

All measurements greater than 2000 ohms: GO TO 8 Any measurement less than 2000 ohms: Faulty crank position sensor input wiring harness – – –1/1 |

|

8 Crank Position Sensor Return Wiring Harness Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Crank position sensor connector and 60-way ECU connector still disconnected 3. Using a multimeter measure resistance between terminal W3 in the harness end of the 60-way ECU connector and: · A good ground · All other terminals in both ECU connectors |

All measurements greater than 2000 ohms: GO TO 9 Any measurement less than 2000 ohms: Faulty crank position sensor return wiring harness – – –1/1 |

|

9 Open in Cam Position Input and Return Wire Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Disconnect cam position sensor connector 3. Disconnect 60-way ECU connector 4. Using a multimeter, measure resistance between: · Terminal A of the cam position sensor harness connector and terminal X1 in the harness end of the 60-way ECU connector · Terminal B of the cam position sensor harness connector and terminal W2 in the harness end of the 60-way ECU connector |

Both measurements 5 ohms or less: GO TO 10 Either measurement greater than 5 ohms: Open in cam position sensor input wire OR Open in cam position sensor return wire OR Terminals A and B in the cam position sensor harness connector possibly inverted – – –1/1 |

|

10 Cam Position Sensor Input Wiring Harness Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Cam position sensor connector and 60-way ECU connector still disconnected 3. Using a multimeter measure resistance between terminal X1 in the harness end of the 60-way ECU connector and: · A good ground · All other terminals in both ECU connectors |

All measurements greater than 2000 ohms: GO TO 11 Any measurement less than 2000 ohms: Faulty cam position sensor input wiring harness – – –1/1 |

|

11 Cam Position Sensor Return Wiring Harness Test |

NOTE: For wiring and theory of operation information, see DTC SPN 637 FMI 7 CRANK POSITION/CAM POSITION OUT OF SYNC supporting information. 1. Ignition OFF 2. Cam position sensor connector and 60-way ECU connector still disconnected 3. Using a multimeter measure resistance between terminal W2 in the harness end of the 60-way ECU connector and: · A good ground · All other terminals in both ECU connectors |

All measurements greater than 2000 ohms: Faulty crank sensor connector OR Faulty cam sensor connector OR Faulty ECU connector OR Faulty ECU Any measurement less than 2000 ohms: Faulty cam position sensor return wiring harness – – –1/1 |