產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢(xún)圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷(xiāo)售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷(xiāo)售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

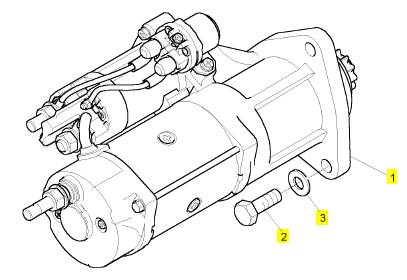

Perkins珀金斯1306-E87TA86柴油發(fā)動(dòng)機(jī)2873 K116啟動(dòng)馬達(dá)

詳細(xì)描述

項(xiàng)目 零配件號(hào)碼 新件號(hào) 描述

1 2873 K116 1 2873 K116 啟動(dòng)馬達(dá)

2 0748663 3 0748663 螺旋

3 0920444 3 0920444 墊圈

|

Peregrine EDi and 1300 Series EDi To fit |

|

Operation 5-2 |

|

Special requirements Consumable products |

|

Description |

|

Part number |

|

POWERPART Silicone RTV sealing and jointing compound |

|

1861108 |

|

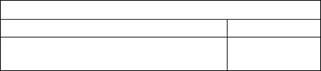

Warning! Use suitable gloves to protect the hands from heat. |

|

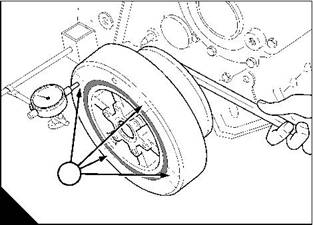

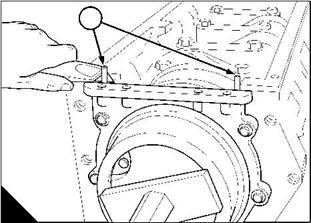

1 Heat the pulley / damper assembly. Do not exceed 198 °C (388 °F) WK, WL, WM, and WN. For WP, WQ, WR, and WS do not exceed 100 °C (212 °F). |

|

Caution: Do not try to fit a cold pulley / damper assembly as this will damage the crankshaft. |

|

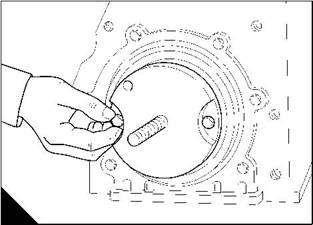

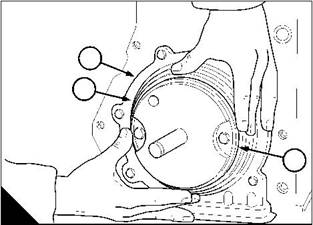

2 Put the pulley assembly on the crankshaft, engage the drive key and push the pulley fully towards the rear. 3 Clean off the old sealant from the retainer plate and from the pulley / damper assembly. |

|

4 Put POWERPART Silicone RTV sealing and jointing compound on the inner face of the retainer plate and fit the retainer plate (A). |

|

5 Lubricate lightly the threads of the setscrews for the retainer plate with clean engine lubricating oil. 6 Fit and tighten the setscrews gradually and evenly to 136 Nm (100 lbf ft) 13,8 kgf m. 7 Fit the fan drive belt, see Operation 12-7. |

|

8 Fill the lubricating sump to the correct level with an approved lubricating oil, see Chapter 5 in the User’s Handbook. |

|

A |

|

W090 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

67 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

To inspect |

|

Operation 5-3 |

|

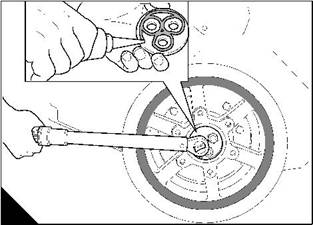

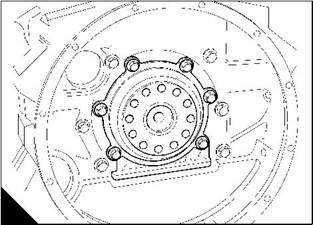

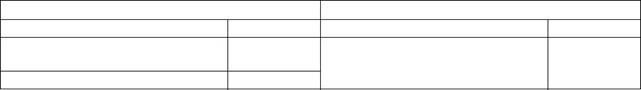

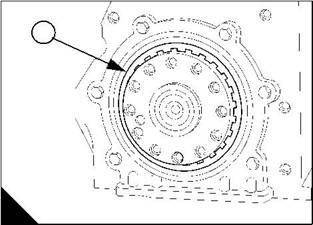

Clean the components and check for damage. The assembly must be renewed if: |

|

l There are cracks in the rubber (A2) l The rubber is damaged by oil |

|

l The component alignment marks (A1) exceed the tolerance in the relevant Data and dimensions for the "Crankshaft assembly" on page 14. |

|

Measure and record damper alignment (B) at four places (B1) 90° apart on the damper face. Ensure that the crankshaft is at the same end of its axial movement for each measurement. This eliminates crankshaft end- float from the measurement. |

|

Before the pulley / damper assembly is removed from the crankshaft, measure and record the run-out of the damper mounting face on the crankshaft palm. |

|

Compare all the readings with the relevant Data and dimensions for the "Crankshaft assembly" on page 14. |

|

1 |

|

1 |

|

2 |

|

A |

|

B |

|

W020 |

|

W021 |

|

68 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

Rear oil seal housing assembly |

|

To remove the oil seal housing |

|

Operation 5-4 |

|

Cautions: |

|

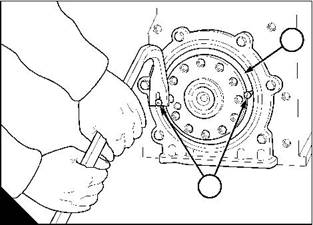

l Renew the rear oil seal and the wear sleeve as a unit, do not separate them. l The flywheel housing does not have to be removed to renew the rear oil seal. 1 Drain the lubricating oil. |

|

2 Remove the lubricating oil sump, see Operation 10-9. 3 Remove the drive components from the rear end of the engine. 4 Remove the flywheel, see Operation 13-1. |

|

5 Remove the rear oil seal, see Operation 5-6. |

|

6 Remove the four setscrews that pass through the flange of the sump and into the bottom of the seal housing. 7 Remove the six setscrews that retain the seal housing to the cylinder block. |

|

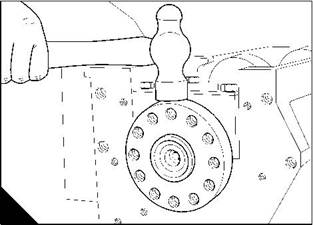

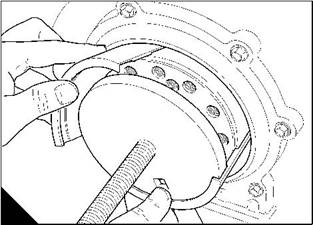

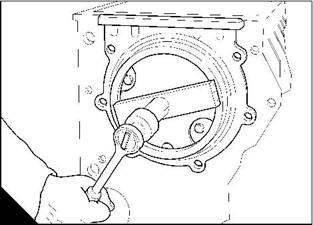

8 Remove the rear oil seal and housing assembly (A). Remove and discard the old oil seal gasket from between the housing and the cylinder block. |

|

9 Hit carefully the outside diameter of the wear sleeve with a hammer to loosen the wear sleeve from the crankshaft (B). |

|

10 Remove the wear sleeve from the crankshaft. |

|

A |

|

B |

|

W045 |

|

W091 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

69 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

To fit the oil seal housing |

|

Operation 5-5 |

|

Special requirements |

|

Special tools |

|

Description |

|

Part number |

|

Rear oil seal installer |

|

21825963 |

|

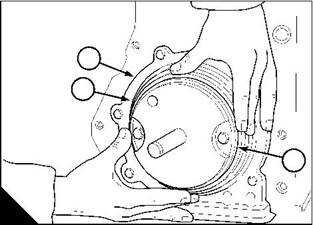

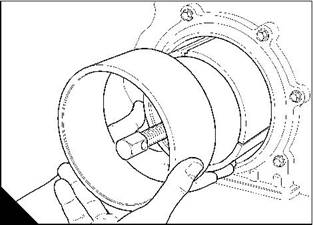

1 Clean the faces of the cylinder block, the oil seal housing and the crankshaft palm. 2 Fit the guide adaptor from tool 21825963 to the end of the crankshaft (A). 3 Fit a new seal (B1) to the oil seal housing face (B3). |

|

4 Put the housing (B2) into position on the engine, fit and tighten the setscrews finger tight. |

|

2 1 |

|

3 |

|

A |

|

B |

|

W092/1 |

|

W093 |

|

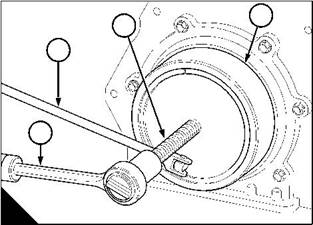

5 Fit the plate from tool 21825963 to the guide adaptor. Tighten the nut of the tool (C) until the plate comes into contact with the face of the housing. |

|

6 Use a straight edge to check that the seal housing is level with the cylinder block face (D). 7 Tighten the setscrews to 24 Nm (18 lbf ft) 2,5 kgf m. |

|

C |

|

D |

|

W048/1 |

|

W046 |

|

Continued |

|

70 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

8 Cut off the excess seal length (E1) so that it is level with the face of the cylinder block. 9 Remove the tool 21825963. |

|

10 Fit the new rear oil seal / wear sleeve and the POSE seal, see Operation 5-6. 11 Fit the lubricating oil sump, see Operation 10-10. |

|

12 Fit the flywheel, see Operation 13-2. |

|

13 Fit the drive components to the rear end of the engine. |

|

14 Fill the lubricating oil sump to the correct level with an approved lubricating oil, see Chapter 5 in the User’s Handbook. |

|

1 |

|

E |

|

W047 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

71 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

To renew the rear oil seal and wear sleeve assembly |

|

Operation 5-6 |

|

Special requirements Special tools |

|

Consumable products |

|

Description |

|

Part number ZTSE 4404 21825963 |

|

Description |

|

Part number |

|

Remover for the wear sleeve of the rear oil seal |

|

POWERPART Compound |

|

1861147 |

|

Rear oil seal installer |

|

Notes: |

|

l The oil seal housing does not have to be removed to renew the rear oil seal and wear sleeve assembly. l The flywheel housing does not have to be removed to renew the rear oil seal and wear sleeve assembly. l Renew the rear oil seal and the wear sleeve as a unit, do not separate them. 1 Drain the lubricating oil. |

|

2 Remove the drive components from the rear end of the engine. 3 Remove the flywheel, see Operation 13-1. |

|

Note: From engine number N1194039, types WP, WQ, WR and WS, a new rear oil seal assembly has been introduced that prevents the entry of debris from the environment. The seal includes a ‘Positive On-Shaft Excluder’ (P.O.S.E.), which extends the life of the seal. |

|

4 Use a suitable smooth tool to remove the POSE seal from the rear oil seal wear sleeve (A). 5 Fit two self-tapping screws (B2) into the front face (B1) of the oil seal. 6 Carefully lever the seal from the seal housing (B). |

|

Caution: Do not damage the seal housing or the crankshaft palm. |

|

1 |

|

2 |

|

A |

|

B |

|

W1386 |

|

W094 |

|

Continued |

|

72 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

![]()

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

7 Fit the remover tool ZTSE 4404 (C) and (D). |

|

C |

|

D |

|

W226 |

|

W227 |

|

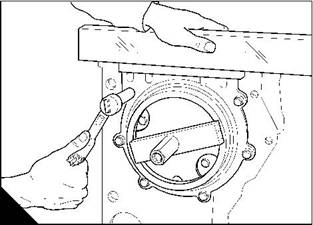

8 Fit a square headed lever (E1) into the 12,7 mm (0.5 in) hole in the front face of the remover tool (E3). |

|

9 Fit a spanner (E4) to the threaded rod (E2) of the remover tool. Hold the lever and tighten the threaded rod with the spanner to remove the wear sleeve. |

|

10 Discard the oil seal and wear sleeve. |

|

11 Clean the oil seal housing and the crankshaft palm. 12 Fit the guide adaptor (F) from tool 21825963 to the end of the crankshaft. |

|

13 Apply POWERPART Compound to the outer diameter of the oil seal and to the inner diameter of the wear sleeve. |

|

Caution: Fit the rear oil seal and the wear sleeve as a unit, do not separate them. |

|

3 |

|

2 |

|

1 |

|

4 |

|

E |

|

F |

|

W228 |

|

W092/1 |

|

Continued |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

73 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

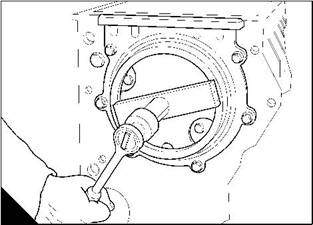

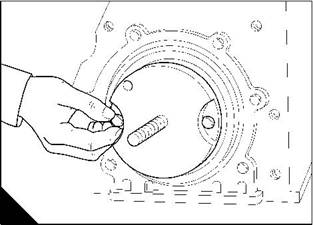

14 Put the oil seal and wear sleeve assembly (G1) into position on the guide adaptor (G3) from tool 21825963. |

|

15 Fit the plate from tool 21825963 to the guide adaptor. Tighten the nut of the tool until the plate comes into contact with the face of the housing (H). |

|

2 1 |

|

3 |

|

G |

|

H |

|

W093 |

|

W048 |

|

Note: When the plate from tool 21825963 comes into contact with the face of the seal housing, the oil seal and the wear sleeve are in their correct positions. |

|

16 Fit the new POS, E seal (J1) to the wear sleeve on the crankshaft palm by hand until it is fully in position. 17 Fit the flywheel, see Operation 13-2. |

|

18 Fit the drive components to the rear end of the engine. |

|

19 Fill the lubricating oil sump to the correct level with an approved lubricating oil, see Chapter 5 in the User’s Handbook. |

|

1 |

|

J |

|

W1385 |

|

74 |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

This document has been printed from SPI². Not for Resale |

![]()

![]()

|

5 |

|

Peregrine EDi and 1300 Series EDi |

|

Crankshaft |

|

To remove |

|

Operation 5-7 |

|

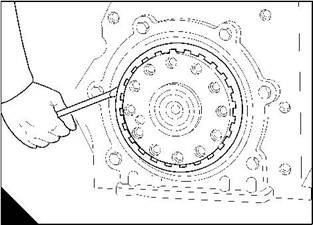

Warning! Use lift equipment or obtain assistance to lift heavy engine components such as the flywheel housing, flywheel and crankshaft. |

|

1 Drain the lubricating oil and the coolant. |

|

2 Remove the lubricating oil sump, see Operation 10-9. 3 Remove the fan drive belt, see Operation 12-7. |

|

4 Remove the fan, see Operation 12-5. |

|

5 Remove the fan drive pulley and fan mounting, see Operation 12-6. 6 Remove the coolant pump, see Operation 12-4. |

|

7 Remove the pulley / damper assembly, see Operation 5-1. 8 Remove the alternator and its mounting bracket, see Operation 14-1. 9 Remove the compressor and its drive assembly, if one is fitted, see Operation 15-1. 10 Remove the timing case cover, see Operation 6-1. 11 Remove the high-pressure pump, see Operation 10-21. 12 Remove the timing case backplate, see Operation 6-5. 13 Remove the flywheel, see Operation 13-1. |

|

14 Remove the flywheel housing, see Operation 13-4. 15 Remove the rear oil seal housing assembly, see Operation 5-4. 16 Remove the lubricating oil suction pipe and strainer, see Operation 10-11. 17 Remove the lubricating oil pump, see Operation 10-12. |

|

18 Remove the big end bearing caps (A) from the connecting rods. Keep the shell-bearings and their shell- bearing caps together. |

|

190 |

|

4 |

|

5 |

|

190 |

|

A |

|

W082/1 |

|

Continued |

|

Workshop Manual, TPD 1353E, Issue 3 |

|

75 |

|

This document has been printed from SPI². Not for Resale |