產(chǎn)品中心

Perkins1204柴油發(fā)動機配件

詳細描述

|

3. Use the electronic service tool to verify the throttle position status. |

|

Note: The turbocharger that is installed on the engine is a nonserviceable item. If any mechanical fault exists, then the turbocharger must be replaced. |

|

4. Run the engine until the speed is equal to the maximum no-load speed. |

|

1. Ensure that the mounting bolts for the turbocharger |

|

are tight. |

|

5. Use the electronic service tool to make sure that the throttle is set to reach the maximum no-load speed. |

|

2. Check that the oil feed for the turbocharger is not blocked or restricted. |

|

6. If the maximum no-load speed cannot be obtained refer to Troubleshooting, “Throttle Switch Circuit - Test” and Troubleshooting, “Mode Selection Circuit - Test”. |

|

3. Check that the oil drain for the turbocharger is not blocked or restricted. |

|

4. Check that the compressor housing for the turbocharger is free of dirt, debris, and damage. |

|

7. If the engine speed is erratic refer to Troubleshooting, “Analog Throttle Position Sensor Circuit - Test” or Troubleshooting, “Digital Throttle Position Sensor Circuit - Test”. |

|

5. Check that the turbine housing for the turbocharger is free of dirt, debris, damage, and oil deposits. |

|

6. Check that the turbine wheel rotates freely in the turbocharger. Make sure that the compressor wheel rotates with the turbine wheel. |

|

8. If the fault has not been eliminated, proceed to “Air Intake and Exhaust System”. |

|

Air Intake and Exhaust System |

|

7. Ensure that the wastegate on the turbocharger is operating correctly. Refer to Systems Operation, Testing and Adjusting, “Turbocharger - Inspect”. If the wastegate actuator is faulty, replace the turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Remove” and Disassembly and Assembly, “Turbocharger - Install”. |

|

1. Check the air filter restriction indicator, if equipped. 2. Ensure that the air filter is clean and serviceable. |

|

3. Check the air intake and the exhaust system for |

|

the following defects: |

|

8. If necessary, replace the turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Remove” and Disassembly and Assembly, “Turbocharger - Install”. |

|

• Blockages |

|

• Restrictions |

|

9. Check that the repairs have eliminated the faults. |

|

• Damage to the air intake and exhaust lines and hoses |

|

10. If the fault has not been eliminated, proceed to |

|

“Fuel Supply”. |

|

4. Make all necessary repairs to the engine. |

|

Turbochargers |

|

5. If the fault has not been eliminated, proceed to |

|

“Valve Lash”. |

|

This procedure is applicable only to engines that have two turbochargers. |

|

Valve Lash |

|

Note: The turbochargers that are installed on the engine are nonserviceable items. If any mechanical fault exists, then the faulty turbocharger must be replaced. |

|

1. Check the valve lash. Refer to Systems Operation, Testing and Adjusting, “Engine Valve Lash - Inspect”. |

|

2. If any repair does not eliminate the fault, proceed to “Turbochargers”. |

|

1. Ensure that the mounting bolts for the turbochargers are tight. |

|

Turbocharger or Turbochargers |

|

2. Check that the oil feeds for the turbochargers are |

|

not blocked or restricted. |

|

Turbocharger |

|

3. Check that the oil drains for the turbochargers are not blocked or restricted. |

|

This procedure is applicable only to engines that have a single turbocharger. |

|

4. Check that the compressor housings for the turbochargers are free of dirt, debris, and damage. |

|

This document is printed from SPI². Not for RESALE |

![]()

|

62 |

|

KENR9116-01 |

|

Troubleshooting Section |

|

5. Check that the turbine housings for the turbochargers are free of dirt, debris, damage, and oil deposits. |

|

11. Check for air in the fuel system. Refer to Systems Operation, Testing and Adjusting, “Air in Fuel - Test”. |

|

6. Check that the turbine wheels rotate freely in the turbochargers. Make sure that the compressor wheels rotate with the turbine wheels. |

|

12. Ensure that the fuel system has been primed. Refer to Systems Operation, Testing and Adjusting, “Fuel System - Prime”. |

|

7. Ensure that the wastegate on the high-pressure turbocharger is operating correctly. Refer to Systems Operation, Testing and Adjusting, “Turbocharger - Inspect”. If the wastegate actuator is faulty, replace the turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Remove” and Disassembly and Assembly, “Turbocharger - Install”. |

|

13. Turn the keyswitch to the OFF position and then disconnect the electrical connector from the EFLP. |

|

14. With the keyswitch in the ON position, measure the voltage at the harness connector for the EFLP. The voltage must be between 10 VDC and 14 VDC for a 12 VDC system. The voltage must be between 20 VDC and 28 VDC for a 24 VDC system. If the voltage is below 10 VDC for a 12 VDC system, investigate the cause. If the voltage is below 20 VDC for a 24 VDC system, investigate the cause. Refer to Troubleshooting, “Fuel Pump Relay Circuit - Test”. |

|

8. If a fault is identified in either turbocharger, replace the affected turbocharger. Refer to Disassembly and Assembly, “Turbocharger - Remove” and Disassembly and Assembly, “Turbocharger - Install”. |

|

15. Turn the keyswitch to the OFF position and then reconnect the electrical connector to the EFLP. |

|

9. Check that the repairs have eliminated the faults. |

|

10. If the fault has not been eliminated, proceed to “Fuel Supply”. |

|

16. If a repair has been performed to rectify a low supply voltage to the EFLP, attempt to start the engine. If the engine does not start, continue with this procedure. |

|

Fuel Supply |

|

Note: Before performing the following fuel system tests, the engine must be stopped for a minimum of 30 minutes. |

|

1. Visually check the fuel tank for fuel. The fuel gauge may be faulty. |

|

2. Ensure that the fuel supply valve (if equipped) is in the full OPEN position. |

|

Note: When performing the following fuel system tests, the Electric Fuel Lift Pump (EFLP) will only operate for 2 minutes unless the engine is running. If necessary, cycle the keyswitch in order to reactivate the pump. |

|

3. If the temperature is below 0 °C (32 °F), check for solidified fuel (wax). |

|

4. Check the primary filter/water separator for water in the fuel. |

|

5. Check for fuel supply lines that are restricted. |

|

6. Check that the low-pressure fuel lines are tight and secured properly. |

|

7. Check that the Electric Fuel Lift Pump (EFLP) is operating. If the EFLP is suspect, refer to Troubleshooting, “Fuel Pump Relay Circuit - Test”. |

|

8. Replace the in-line fuel strainer that is installed upstream from the EFLP. |

|

9. Replace the primary fuel filter and the secondary fuel filter. Refer to the Operation and Maintenance Manual, “Fuel System Primary Filter (Water Separator) Element - Replace”. |

|

10. Check the diesel fuel for contamination. Refer to Systems Operation, Testing and Adjusting, “Fuel Quality - Test”. |

|

This document is printed from SPI². Not for RESALE |

![]()

|

KENR9116-01 |

|

63 Troubleshooting Section |

|

1. Disconnect the TPIR return line from the drain port on the TPIR. Install a suitable blanking cap on the open port in the TPIR return line |

|

2. Connect a temporary drain line to the drain port on the TPIR. |

|

3. Place the end of the temporary drain line into a suitable calibrated container. |

|

4. With the keyswitch in the ON position but the engine not running, use a suitable multimeter to measure the input voltage to the EFLP. Record the reading. |

|

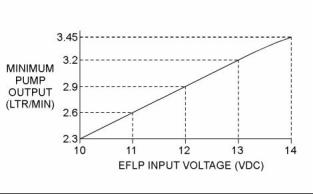

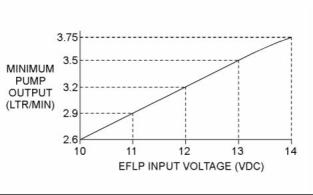

5. With the keyswitch in the ON position but the engine not running, measure the fuel flow from the temporary drain line. |

|

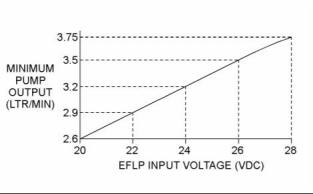

• For a 12 VDC system on a 1204E engine, refer to Illustration 31 for the minimum acceptable flow rate. |

|

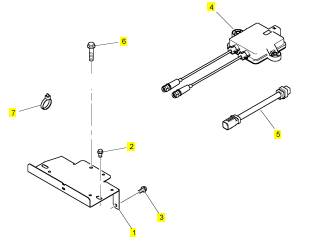

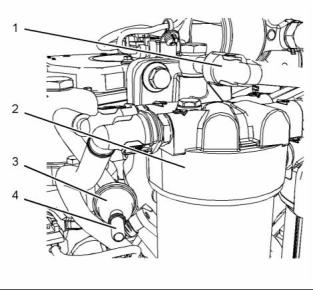

g02525302 |

|

Illustration 29 |

|

Locations on the low-pressure fuel system on a 1204E engine |

|

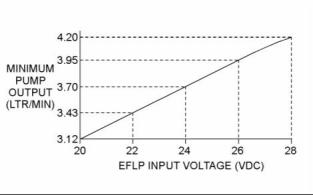

• For a 24 VDC system on a 1204E engine, refer to Illustration 32 for the minimum acceptable flow rate. |

|

(1) Fuel return to the secondary fuel filter (2) Secondary fuel filter base (3) Transfer pump inlet regulator (TPIR) (4) Transfer pump inlet regulator return port |

|

• For a 12 VDC system on a 1206E engine, refer to Illustration 33 for the minimum acceptable flow rate. |

|

• For a 24 VDC system on a 1206E engine, refer to Illustration 34 for the minimum acceptable flow rate. |

|

g02526956 |

|

Illustration 30 |

|

g02485896 |

|

Illustration 31 |

|

Locations on the low-pressure fuel system on a 1206E engine |

|

Minimum TPIR flow rate for a 1204E engine with a 12 VDC system |

|

(1) Fuel return to the secondary fuel filter (2) Secondary fuel filter base (3) Transfer pump inlet regulator (TPIR) (4) Transfer pump inlet regulator return port |

|

Transfer Pump Inlet Regulator (TPIR) Flow Test |

|

For a 1204E engine, refer to Illustration 29. For a 1206E engine, refer to Illustration 30. |

|

Perform the following procedure: |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

![]()

|

64 |

|

KENR9116-01 |

|

Troubleshooting Section |

|

Return Pressure Relief Valve Test |

|

Use the following procedure to check the fuel flow through the return pressure relief valve in the secondary fuel filter base: |

|

1. Disconnect the return line (1) from the secondary fuel filter base and install a blank on the line. Install a temporary line and a calibrated container to the filter base. |

|

2. With the keyswitch in the ON position, measure fuel flow from the temporary line. |

|

3. If the fuel flow is more than 300 mL/min (10.2 oz/min), replace the secondary fuel filter base. Refer to Disassembly and Assembly, “Fuel Filter Base - Remove and Install (Twin Secondary Fuel Filter)”. |

|

g02485897 |

|

Illustration 32 |

|

Minimum TPIR flow rate for a 1204E engine with a 24 VDC system |

|

4. Remove the temporary line and reconnect the return line. |

|

5. If the secondary fuel filter base has been replaced, attempt to start the engine. If the engine does not start, use the following procedure to check the fuel flow from the EFLP: |

|

6. Disconnect the fuel inlet from the primary fuel filter. Place the open end of the disconnected line into a calibrated container. |

|

g02355128 |

|

Illustration 33 |

|

7. With the keyswitch in the ON position, measure the flow from the fuel line. Refer to the Illustration 35 for the minimum acceptable fuel flow on a 12 VDC system. Refer to the Illustration 36 for the minimum acceptable fuel flow on a 24 VDC system. |

|

Minimum TPIR flow rate for a 1206E engine with a 12 VDC system |

|

g02355130 |

|

Illustration 34 |

|

Minimum TPIR flow rate for a 1206E engine with a 24 VDC system |

|

6. Remove the temporary drain line from the drain port on the TPIR. Connect the TPIR return line to the TPIR. |

|

g02527498 |

|

Illustration 35 |

|

Minimum EFLP flow rate for a 12 VDC system |

|

7. If the fuel flow in Step 5 is greater than the minimum limit, proceed to “Low Compression (Cylinder Pressure)”. |

|

8. If the fuel flow in Step 5 is below the minimum limit, proceed to “Return Pressure Relief Valve Test”. |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

![]()

![]()

![]()

|

KENR9116-01 |

|

65 Troubleshooting Section |

|

• Worn valves |

|

• Faulty cylinder head gasket |

|

• Damaged cylinder head |

|

3. Perform all necessary repairs. 4. Ensure that the repairs have eliminated the faults. |

|

5. If no faults are detected, proceed to “Electronic Unit Injectors”. |

|

Electronic Unit Injectors |

|

g02527518 |

|

Illustration 36 |

|

1. Use the electronic service tool to perform the automatic “Cylinder Cut Out Test”. If the compression test that was performed in “Low Compression (Cylinder Pressure)” was satisfactory, the “Cylinder Cut Out Test” will identify any faulty injectors. |

|

Minimum EFLP flow rate for a 24 VDC system |

|

8. If the fuel flow is more than 5% below the |

|

acceptable limit, replace the EFLP. |

|

9. If the fuel flow is more than 5% above the acceptable limit, contact Perkins Global Technical Support. |

|

2. Remove any faulty electronic unit injectors. Refer to Disassembly and Assembly, “Electronic Unit Injector - Remove”. |

|

10. If the fuel flow from the EFLP is within limits, |

proceed to “Check the Return Fuel Lines”.

|

3. Install new electronic unit injectors. Refer to Disassembly and Assembly, “Electronic Unit Injector - Install”. |

|

Check the Return Fuel Lines |

|

1. Make sure that the TPIR return line is not blocked or kinked. |

|

4. Repeat the test in 1. If the fault is still apparent, remove the replacement electronic unit injector and install the original electronic unit injector. Refer to Disassembly and Assembly, “Electronic Unit Injector - Remove” and Disassembly and Assembly, “Electronic Unit Injector - Install”. |

|

2. If the TPIR return line is clear, confirm that the Electric Fuel Lift Pump (EFLP) is operating. Make sure that fuel lines between the EFLP and the TPIR are not blocked or kinked. |

|

5. If the repair does not eliminate the fault, refer to “Individual Malfunctioning Cylinders”. |

|

3. If the fuel lines to the TPIR are clear and the EFLP is operating, replace the TPIR. |

|

Individual Malfunctioning Cylinders |

|

4. If the fault is still present, proceed to “Low |

|

Compression (Cylinder Pressure)”. |

|

1. With the engine speed at a fast idle, use the electronic service tool to perform the manual “Cylinder Cut Out Test”. As each cylinder is cut out, listen for a change in the sound from the engine. When a cylinder is cut out, there should be a noticeable change in the sound of the engine. If a change in the sound of the engine is not noted, the isolated cylinder is not operating under normal conditions. If the isolation of a cylinder results in a change that is less noticeable, the cylinder is operating below normal performance. Investigate the cause of the fault on any cylinder that is not operating. Investigate the cause of the fault on any cylinder that is operating below normal performance. |

|

Low Compression (Cylinder Pressure) |

|

1. Perform a compression test. Refer to Systems Operation, Testing and Adjusting, “Compression - Test ”. |

|

2. If low compression is noted on any cylinders, investigate the cause and rectify any faults. |

|

Possible causes of low compression are shown in the following list: |

|

• Loose glow plugs • Faulty piston |

|

2. If the fault is not eliminated, repeat this test |

|

procedure from Test Step 1. |

|

• Faulty piston rings • Worn cylinder bores |

|

This document is printed from SPI². Not for RESALE |

![]()

![]()

|

66 |

|

KENR9116-01 |

|

Troubleshooting Section |

|

i04079191 |

|

i04079192 |

|

Alternator Is Noisy |

|

Alternator Problem |

|

Refer to Systems Operation, Testing, and Adjusting for information on possible electrical causes of this condition. |

|

Probable Causes • Alternator drive belt • Charging circuit • Alternator |

|

Probable Causes • Alternator drive belt |

|

• Alternator mounting bracket • Alternator drive pulley • Alternator bearings |

|

Recommended Actions |

|

Alternator Drive Belt |

|

Inspect the condition of the alternator drive belt. If the alternator drive belt is worn or damaged, check that the drive belt for the alternator and the pulley are correctly aligned. If the alignment is correct, replace the drive belt. Refer to Disassembly and Assembly, “Alternator Belt - Remove and Install”. |

|

Recommended Actions |

|

Alternator Drive Belt |

|

Inspect the condition of the alternator drive belt. If the alternator drive belt is worn or damaged, check that the drive belt for the alternator and the pulley are correctly aligned. If the alignment is correct, replace the drive belt. Refer to Disassembly and Assembly, “Alternator Belt - Remove and Install”. |

|

Charging Circuit |

|

Inspect the battery cables, wiring, and connections in the charging circuit. Clean all connections and tighten all connections. Replace any faulty parts. |

|

Alternator Mounting Bracket |

|

Alternator |

|

Inspect the alternator mounting bracket for cracks and wear. Repair the mounting bracket or replace the mounting bracket. Ensure that the alternator drive belt and the alternator drive pulley are in alignment. |

|

Verify that the alternator is operating correctly. Refer to Systems Operation, Testing, and Adjusting, “Alternator - Test”. The alternator is not a serviceable item. The alternator must be replaced if the alternator is not operating correctly. Refer to Disassembly and Assembly, “Alternator - Remove” and Disassembly and Assembly , “Alternator - Install”. |

|

Alternator Drive Pulley |

|

Remove the nut for the alternator drive pulley and then inspect the nut and the drive shaft. If no damage is found, install the nut and tighten the nut to the correct torque. Refer to Disassembly and Assembly, “Alternator - Install” for the correct torque. |

|

i04079193 |

|

Battery Problem |

|

Alternator Bearings |

|

Probable Causes • Charging circuit • Battery |

|

Check for excessive play of the shaft in the alternator. Check for wear in the alternator bearings. The alternator is a nonserviceable item. The alternator must be replaced if the bearings are worn. Refer to Disassembly and Assembly, “Alternator - Remove” and Disassembly and Assembly , “Alternator - Install”. |

|

• Auxiliary device |

|

This document is printed from SPI². Not for RESALE |

![]()

|

KENR9116-01 |

|

67 Troubleshooting Section |

|

Recommended Actions |

|

Cylinder Head Gasket |

|

Charging Circuit |

|

1. Remove the cylinder head. Refer to Disassembly and Assembly, “Cylinder Head - Remove” for the correct procedure. |

|

If a fault in the battery charging circuit is suspected, refer to Troubleshooting, “Alternator Problem”. |

|

2. Inspect the cylinder head gasket for faults and any |

|

signs of leakage. |

|

Faulty Battery |

|

3. Proceed to the recommended actions for the “Cylinder Head”. |

|

1. Check that the battery is able to maintain a charge. Refer to Systems Operation, Testing, and Adjusting, “Battery - Test”. |

|

Cylinder Head |

|

2. If the battery does not maintain a charge, replace the battery. Refer to the Operation and Maintenance Manual, “Battery - Replace”. |

|

1. Check the cylinder head for flatness. Refer to Systems Operation, Testing, and Adjusting, “Cylinder Head - Inspect” for the correct procedure. |

|

Auxiliary Device |

|

2. Check the mating face of the cylinder head for faults and signs of leakage. If a fault is found, replace the cylinder head. If signs of leakage are found, determine the cause of the leakage. Refer to Systems Operation, Testing, and Adjusting, “Cylinder Head - Inspect” for the correct procedure. |

|

1. Check if an auxiliary device has drained the battery by being left in the ON position. |

|

2. Charge the battery. |

|

3. Verify that the battery is able to maintain a charge |

|

when all auxiliary devices are switched off. |

|

3. Proceed to “Cylinder Block”. |

|

Cylinder Block |

|

i04079194 |

|

Coolant Contains Oil |

|

Inspect the top face of the cylinder block for faults and signs of leakage. If a fault is found, replace the cylinder block. If signs of leakage are found, determine the cause of the leakage. Refer to Systems Operation, Testing, and Adjusting, “Cylinder Block - Inspect” for the correct procedure. |

|

Probable Causes • Engine oil cooler • Cylinder head gasket • Cylinder head |

|

Assembly after Repair |

|

1. Install the cylinder head. Refer to Disassembly and Assembly, “Cylinder Head - Install”. |

|

• Cylinder block |

|

2. Replenish the engine with clean engine oil to the correct level. Refer to the Operation and Maintenance Manual, “Engine Oil and Filter - Change” for more information. |

|

Recommended Actions |

|

Engine Oil Cooler |

|

3. Fill the cooling system. Refer to the Operation and Maintenance Manual, “Cooling System Coolant (ELC) - Change”. |

|

1. Drain the coolant from the cooling system. Drain the lubricating oil from the engine oil cooler. Refer to the Operation and Maintenance Manual for more information. |

|

i03860850 |

|

Coolant Level Is Low |

|

2. Check for leaks in the oil cooler assembly. Refer to Systems Operation, Testing, and Adjusting, “Cooling System” for the correct procedure. If a leak is found, install a new oil cooler. Refer to Disassembly and Assembly, “Engine Oil Cooler - Remove” and Disassembly and Assembly, “Engine Oil Cooler - Install” for the correct procedure. |

|

This diagnostic trouble code is only applicable if the optional coolant level switch is installed. |

|

This procedure covers the following diagnostic code: |

|

This document is printed from SPI². Not for RESALE |

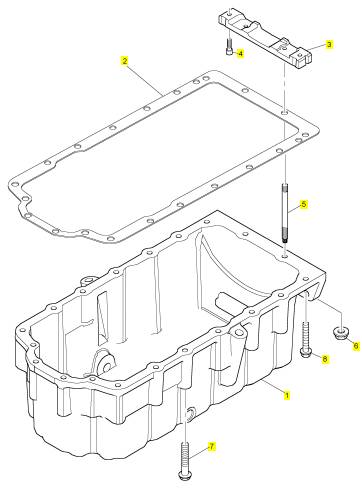

1 T408653 1 T408653 油底殼

2 3681 K037 1 3681 K037 密封墊片 -油底殼

3 T407009 1 T407009 氣門

4 2311 D039 2 2311 D039 螺旋

5 3211 P013 2 3211 P013 圖釘

6 2318 A603 2 2318 A603 螺帽

7 2314 H017 16 2314 H017 螺旋

8 2314 H004 2 2314 H004 螺旋

項目 零配件號碼 新件號 描述

1 T405830 1 T405830 曲軸皮帶輪

2 32186146 3 32186146 螺拴

項目 零配件號碼 新件號 描述

1 2654407 1 2654407 濾油器

項目 零配件號碼 新件號 描述

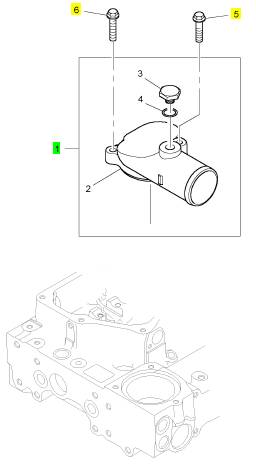

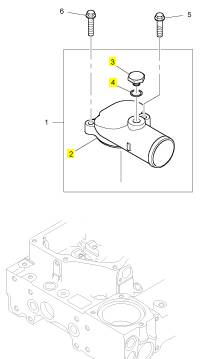

1 T414228 1 T414228 恒溫節(jié)溫器組合

1 T409197 1 T414228 恒溫節(jié)溫器組合

5 2314 H013 1 2314 H013 螺旋

6 2314 H005 2 2314 H005 螺旋

項目 零配件號碼 新件號 描述

2 1 恒溫節(jié)溫器殼

3 T409183 1 T409183 栓塞

4 T409162 1 T409162 密封O型圈

項目 零配件號碼 新件號 描述

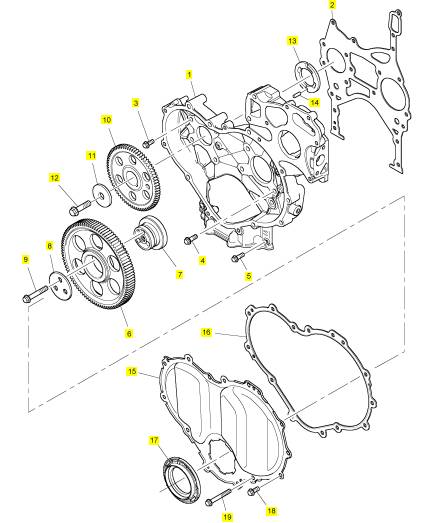

1 T405518 1 T405518 時間安排箱

2 T405410 1 T405410 密封墊片 - 正時齒輪箱

3 2314 H003 7 2314 H003 螺旋

4 2314 H006 2 2314 H006 螺拴

5 2314 H034 3 2314 H034 螺旋

6 T407065 1 T407065 惰輪傳動機構(gòu)

7 T416351 1 T416351 輪轂

7 T406834 1 T416351 輪轂

8 T406040 1 T406040 板

9 2314 J010 3 2314 J010 螺旋

10 T407464 1 T407464 凸輪軸傳動機構(gòu)

11 3321 A003 1 3321 A003 墊圈

12 2314 J606 1 2314 J606 螺旋

13 3112 X011 1 3112 X011 推力墊圈

14 2116053 1 2116053 合釘

15 T410624 1 T410624 正時齒輪蓋

16 T406926 1 T406926 密封墊片 - 正時齒輪箱蓋

17 T410666 1 T410666 密封 -前油封

18 2314 H003 9 2314 H003 螺旋

19 2314 H012 5 2314 H012 螺旋

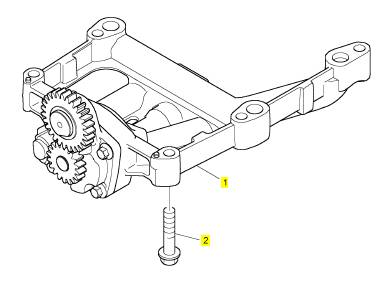

項目 零配件號碼 新件號 描述

1 T407944 1 T407944 油泵

2 2314 J008 5 2314 J008 螺旋

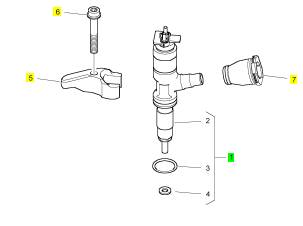

項目 零配件號碼 新件號 描述

1 T409980 4 T409980 噴油器

5 T406394 4 T406394 噴油器砂箱夾

6 3218 A016 4 3218 A016 螺旋

7 T407139 4 T407139 綁腿

項目 零配件號碼 新件號 描述

2 1 噴油器

3 T406053 1 T406053 密封O型圈

4 T405750 1 T405750 噴油器墊圈

項目 零配件號碼 新件號 描述

1 T405402 1 T405402 啟動馬達

2 2313 C077 3 2313 C077 圖釘

3 2318 A604 3 2318 A604 螺帽

項目 零配件號碼 新件號 描述

1 T413421 1 T413421 水泵裝備

10 2314 H006 3 2314 H006 螺拴

11 2314 K166 4 2314 K166 螺旋

12 T407489 1 T407489 連接

16 2314 F004 2 2314 F004 螺旋

項目 零配件號碼 新件號 描述

2 1 水泵

9 T407626 1 T407626 密封墊片 - 水的泵

項目 零配件號碼 新件號 描述

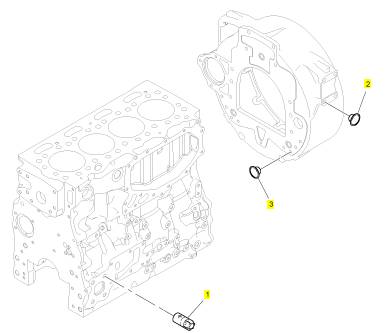

1 3212 V004 4 3212 V004 栓塞

2 2487207 4 2487207 栓塞

3 2487207 6 2487207 栓塞

項目 零配件號碼 新件號 描述

1 T406408 1 T406408 風扇輪廓總成

2 3115 Y011 1 3115 Y011 風扇皮皮帶輪

3 2314 J004 4 2314 J004 螺旋

4 3652970 1 3652970 皮帶

項目 零配件號碼 新件號 描述

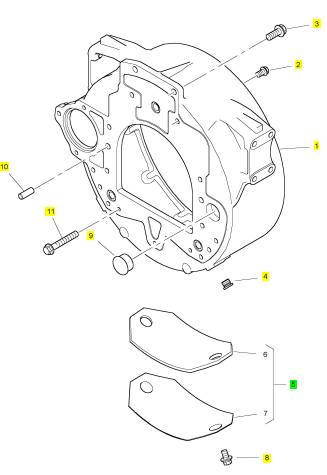

1 T405695 1 T405695 飛輪殼

2 2314 H030 2 2314 H030 螺旋

3 2314 J204 6 2314 J204 螺旋

4 T410815 2 T410815 栓塞

5 4148 K019 1 4148 K019 板

8 2314 J603 2 2314 J603 螺旋

9 2487 A452 1 2487 A452 栓塞

10 3245 A011 2 3245 A011 合釘

11 2314 J004 3 2314 J004 螺旋

項目 零配件號碼 新件號 描述

1 T408625 1 T408625 凸輪軸

4 3142 V011 8 3142 V011 PUSHROD

4 T405746 8 3142 V011 PUSHROD

5 T411902 8 T411902 挺桿

5 T405810 8 T411902 挺桿

項目 零配件號碼 新件號 描述

1 T405541 1 T405541 BUSBAR

2 T409125 4 T409125 GLOWPLUG

3 3881 A006 1 3881 A006 絕緣體

4 2318 A207 1 2318 A207 螺帽

5 2314 C038 1 2314 C038 螺旋

6 2487 F201 1 2487 F201 帽

項目 零配件號碼 新件號 描述

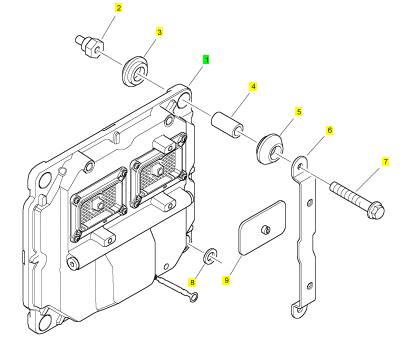

1 T400052 1 T400052 引擎控制組件ECM電腦控制模塊

2 T405430 4 T405430 間隔器

3 2634 C501 4 2634 C501 架設(shè)

4 3313 A027 4 3313 A027 間隔器

5 2634 C501 4 2634 C501 架設(shè)

6 T405497 2 T405497, 托架

7 2314 H008 4 2314 H008 螺旋

8 2131 A008 1 2131 A008 墊圈

9 CH12655 1 CH12655 蓋

項目 零配件號碼 新件號 描述

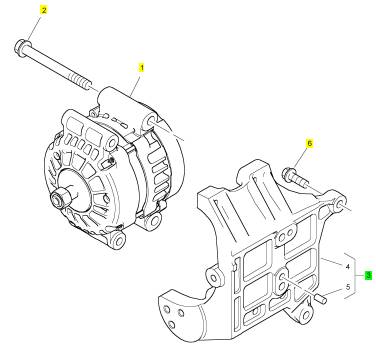

1 T405758 1 T405758 交流充電發(fā)電機

2 2314 J017 4 2314 J017 螺旋

3 T407399 1 T407399 交流充電發(fā)電機托架

6 2314 J005 4 2314 J005 螺旋

項目 零配件號碼 新件號 描述

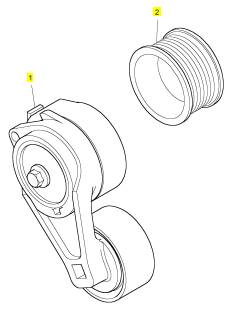

1 T411130 1 T411130 張緊輪

2 T407371 1 T407371 皮帶輪

項目 零配件號碼 新件號 描述

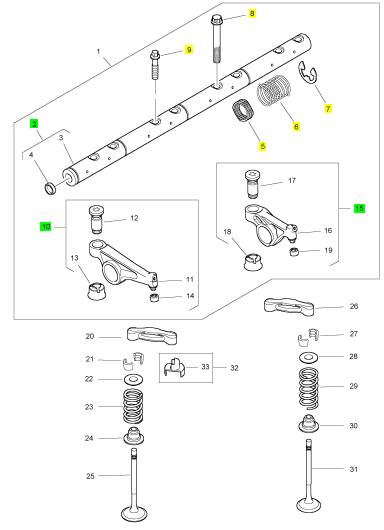

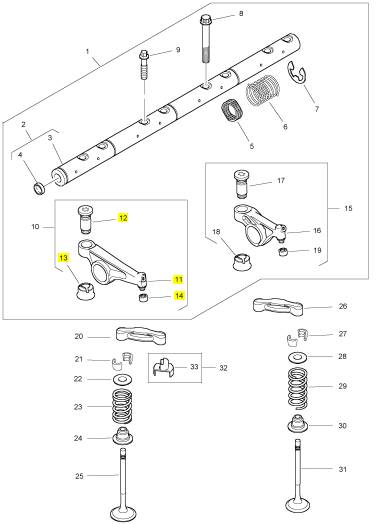

T406575 4 T407502 氣門

1 T407569 1 T407569 搖臂軸組合

20 T407502 4 T407502 氣門

20 T406575 4 T407502 氣門

21 3142 W003 8 3142 W003 閥筒夾

22 T406809 8 T406809 承件

23 T417714 8 T417714 閥彈簧

23 T407056 8 T417714 閥彈簧

24 T412573 8 T412573 氣門油封

24 T407967 8 T407967 氣門油封

25 T406777 8 T406777 進氣門

26 T407502 4 T407502 氣門

26 T406575 4 T407502 氣門

27 3142 W003 8 3142 W003 閥筒夾

28 T406809 8 T406809 承件

29 T417519 8 T417519 閥彈簧

29 3174 A026 8 T417519 閥彈簧

30 T412573 8 T412573 氣門油封

30 T407967 8 T407967 氣門油封

31 T405211 8 T405211 排氣閥

32 T416277 1 T416277 承件

項目 零配件號碼 新件號 描述

2 T406591 1 T406591 搖臂軸組合

5 3174 A024 1 3174 A024 搖臂軸彈簧

6 T407095 3 T407095 搖臂軸彈簧

7 2727 A015 4 2727 A015 CIRCLIP

8 2316 A901 1 2316 A901 螺旋

9 T406016 7 T406016 螺拴

10 T407570 4 T407570 搖臂組合

15 T406261 4 T406261 搖臂組合

項目 零配件號碼 新件號 描述

11 1 搖臂

12 T407571 1 T407571 搖臂氣門調(diào)整

13 T406029 1 T406029 導(dǎo)入

14 1 碗

項目 零配件號碼 新件號 描述

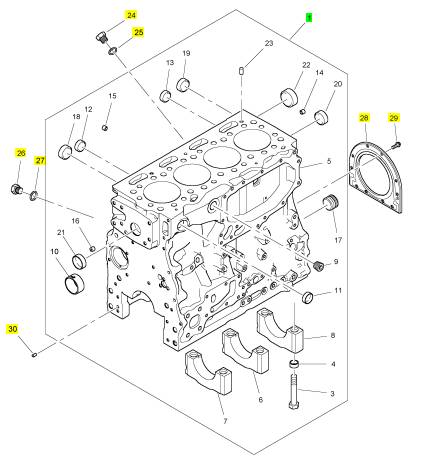

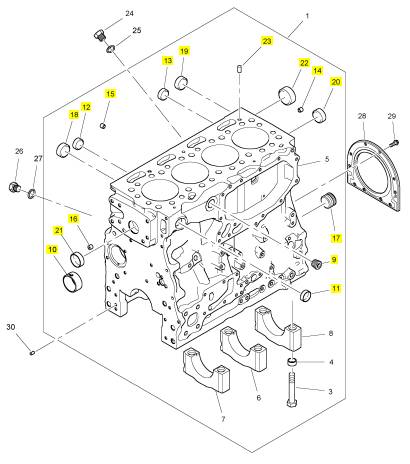

1 1 缸體組合

24 3278 A006 1 3278 A006 栓塞

25 2415 H519 1 2415 H519 密封O型圈

26 3278 A006 1 3278 A006 栓塞

27 2415 H003 1 2415 H003 密封O型圈

28 2418 F704 1 2418 F704 密封 - 再操作系統(tǒng)殼

29 3211 C002 10 3211 C002 公制的螺拴

30 0350010 1 0350010 合釘

項目 零配件號碼 新件號 描述

2 1 缸體組合

9 0650588 1 0650588 栓塞

10 T410164 1 T410164 凸輪軸襯套

11 0650710 1 0650710 栓塞

12 0650710 1 0650710 栓塞

13 0650710 1 0650710 栓塞

14 2485 A309 1 2485 A309 栓塞

15 2485 A309 1 2485 A309 栓塞

16 2485 A309 1 2485 A309 栓塞

17 3212 P008 1 3212 P008 栓塞

18 3241 A011 1 3241 A011 栓塞

19 3241 A011 1 3241 A011 栓塞

20 3241 A011 1 3241 A011 栓塞

21 3241 A011 1 3241 A011 栓塞

22 3241 A012 1 3241 A012 栓塞

23 3244 A009 2 3244 A009 合釘

項目 零配件號碼 新件號 描述

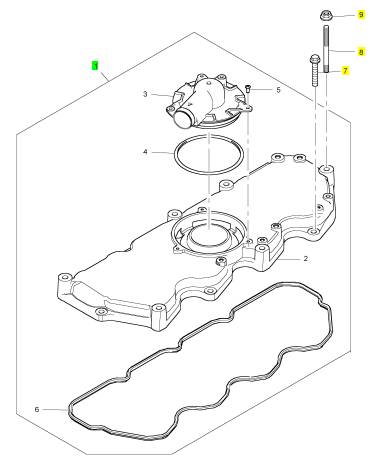

1 T408342 1 T408342 CYL 座蓋 ASSY

7 2314 H004 5 2314 H004 螺旋

8 T412761 6 T412761 圖釘

8 2313 H245 6 2313 H245 圖釘

9 2318 A603 6 2318 A603 螺帽

項目 零配件號碼 新件號 描述

2 1 汽缸蓋蓋

3 T406923 1 T406923 帽

4 1 密封O型圈

5 2152 A034 3 2152 A034 螺旋

6 T400093 1 T400093 密封

項目 零配件號碼 新件號 描述

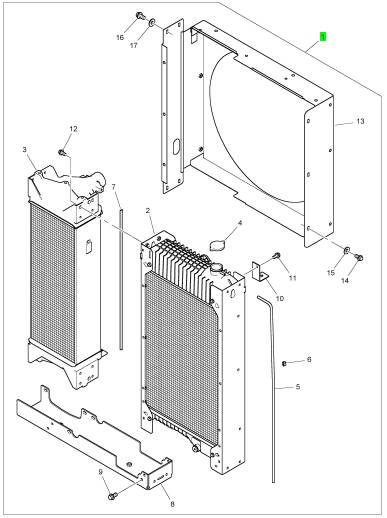

1 T409957 1 T409957 散熱器

項目 零配件號碼 新件號 描述

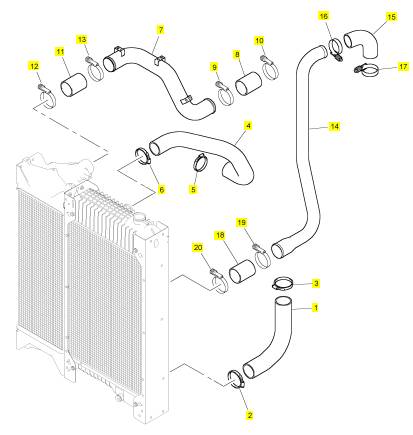

1 T410366 1 T410366 水管 -冷卻器

2 21825194 1 21825194 夾

2 2481 D074 1 2481 D074 水管夾

3 21825194 1 21825194 夾

3 2481 D074 1 2481 D074 水管夾

4 T410369 1 T410369 水管 -冷卻器

5 21825194 1 21825194 夾

5 2481 D074 1 2481 D074 水管夾

6 21825194 1 21825194 夾

6 2481 D074 1 2481 D074 水管夾

7 T409672 1 T409672 水管 -空氣

8 T408187 1 T408187 水管 -空氣

9 T411155 1 T411155 水管夾

10 T411155 1 T411155 水管夾

11 T408187 1 T408187 水管 -空氣

12 T411155 1 T411155 水管夾

13 T411155 1 T411155 水管夾

14 T411384 1 T411384 水管 -空氣

15 T409696 1 T409696 水管 -空氣

16 T411491 1 T411491 砂箱夾

17 T411491 1 T411491 砂箱夾

18 T408187 1 T408187 水管 -空氣

19 T411155 1 T411155 水管夾

20 T411155 1 T411155 水管夾

項目 零配件號碼 新件號 描述

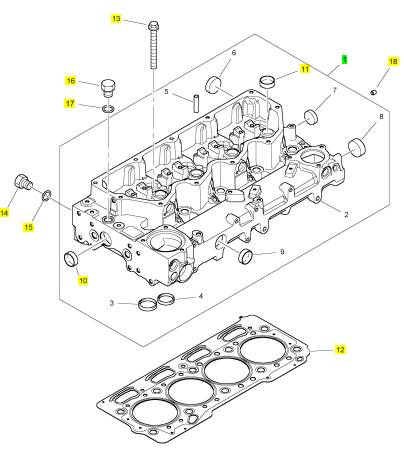

1 1 汽缸蓋組合

10 T412814 1 T412814 密封墊片 - 汽缸蓋

10 T406619 1 T412814 密封墊片 - 汽缸蓋

(10) T414453 1 T414453 密封墊片 - 汽缸蓋

(10) T414454 1 T414454 密封墊片 - 汽缸蓋

11 3218 A017 8 3218 A017 汽缸蓋螺拴

12 3278 A006 1 3278 A006 栓塞

12 T412814 1 T412814 密封墊片 - 汽缸蓋

12 T406619 1 T412814 密封墊片 - 汽缸蓋

(12) T414453 1 T414453 密封墊片 - 汽缸蓋

(12) T414454 1 T414454 密封墊片 - 汽缸蓋

13 2415 H003 1 2415 H003 密封O型圈

13 3218 A017 8 3218 A017 汽缸蓋螺拴

14 3278 A006 1 3278 A006 栓塞

15 2415 H003 1 2415 H003 密封O型圈

16 2485 A307 1 2485 A307 栓塞

16 3278 A006 1 3278 A006 栓塞

17 2415 H003 1 2415 H003 密封O型圈

18 2485 A307 1 2485 A307 栓塞

項目 零配件號碼 新件號 描述

2 1 汽缸蓋

3 T407000 8 T407000 氣門座圈

4 T406545 8 T406545 氣門座圈

5 T407959 16 T407959 氣門導(dǎo)管

6 2485 A519 8 2485 A519 栓塞

7 2485 A519 1 2485 A519 栓塞

8 2485 A524 1 2485 A524 栓塞

9 2485 A524 1 2485 A524 栓塞

10 2485 A524 1 2485 A524 栓塞

11 2485 A517 4 2485 A517 栓塞

項目 零配件號碼 新件號 描述

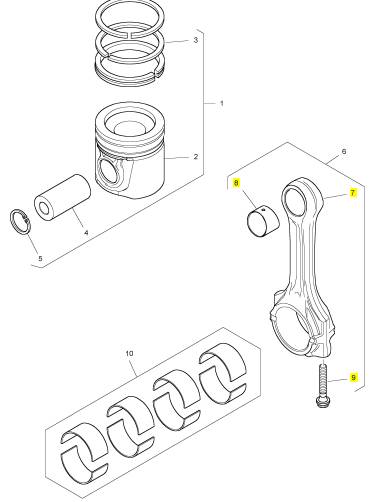

1 T410925 4 T410925 活塞及圈裝備

(1) T400435 4 T400435 活塞及圈裝備 -O/S

(1) T400436 4 T400436 活塞及圈裝備 -O/S

6 T405102 4 T405102 連桿組合

10 T410927 1 T410927 大頭軸承裝備

(10) T420153 1 T420153 大頭 BRG 裝備 -U/S

(10) T420154 1 T420154 大頭 BRG 裝備 -U/S

(10) T420155 1 T420155 大頭 BRG 裝備 -U/S

項目 零配件號碼 新件號 描述

2 1 活塞及圈裝備

6 2721332 2 2721332 CIRCLIP /S

項目 零配件號碼 新件號 描述

7 1 連桿

8 3112 E031 1 3112 E031 連桿小的一端襯套

9 T400001 2 T400001 連桿螺拴

項目 零配件號碼 新件號 描述

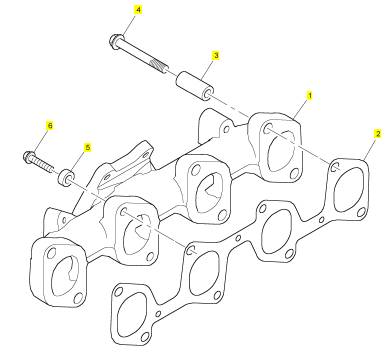

1 T408960 1 T408960 排氣岐管

2 T407220 1 T407220 密封墊片

3 T405957 7 T405957 間隔器

4 3218 J025 7 3218 J025 螺旋

5 T407523 1 T407523 間隔器

6 3218 A018 1 3218 A018 螺旋

項目 零配件號碼 新件號 描述

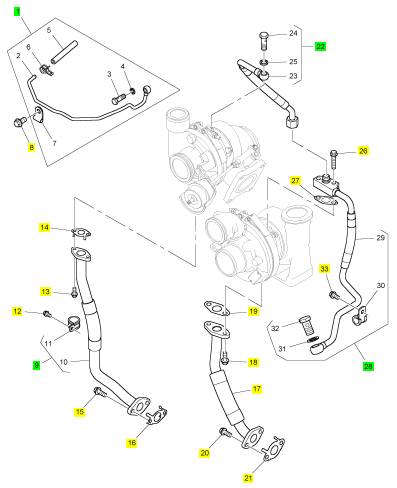

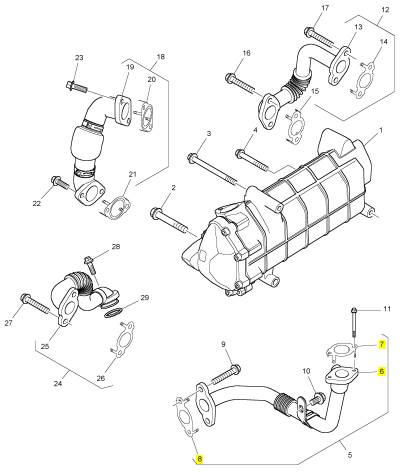

1 T409045 1 T409045 管 -推進

8 2314 H002 1 2314 H002 螺旋

9 T408933 1 T408933 管 - 渦輪增壓器的油排泄

12 2314 H002 1 2314 H002 螺旋

13 2314 H003 2 2314 H003 螺旋

14 T408054 1 T408054 密封墊片

15 2314 F004 2 2314 F004 螺旋

16 T407852 1 T407852 密封墊片

17 T408948 1 T408948 管 - 渦輪增壓器的油排泄

18 2314 H003 2 2314 H003 螺旋

19 CH11561 1 CH11561 密封墊片

20 2314 H003 2 2314 H003 螺旋

21 T408054 1 T408054 密封墊片

22 T408935 1 T408935 管 - 渦輪增壓器的油補給

26 2314 H005 2 2314 H005 螺旋

27 CH12205 1 CH12205 密封墊片

28 T408941 1 T408941 管 - 渦輪增壓器的油補給

33 2314 H002 1 2314 H002 螺旋

項目 零配件號碼 新件號 描述

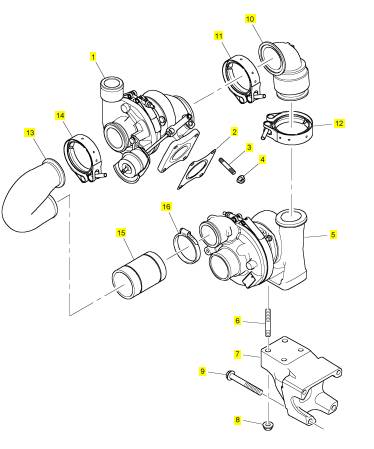

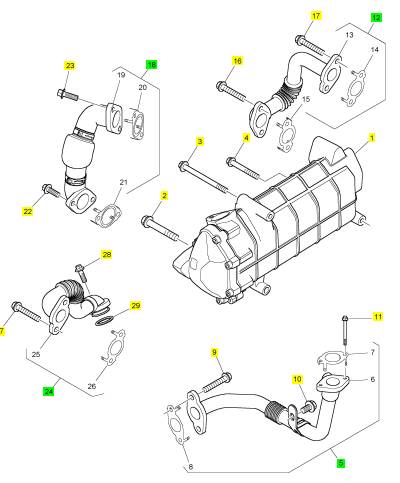

1 T413586 1 T413586 渦輪增壓器

1 T409033 1 T413586 渦輪增壓器

2 T407547 1 T407547 密封墊片 -渦輪增壓器

3 2313 M359 4 2313 M359 圖釘

4 2318 A633 4 2318 A633 螺帽

5 T414287 1 T414287 渦輪增壓器

5 T409029 1 T414287 渦輪增壓器

5 T413587 1 T414287 渦輪增壓器

6 2313 M383 4 2313 M383 圖釘

7 T409003 1 T409003 托架

8 2318 A634 4 2318 A634 螺帽

9 2314 J013 4 2314 J013 螺旋

10 T407900 1 T407900 排氣肘管

11 T406192 1 T406192 砂箱夾

12 T407169 1 T407169 砂箱夾

13 T409032 1 T409032 導(dǎo)氣管

14 T407169 1 T407169 砂箱夾 , ;

15 T407961 1 T407961 水管

16 2481 D075 2 2481 D075 水管夾

項目 零配件號碼 新件號 描述

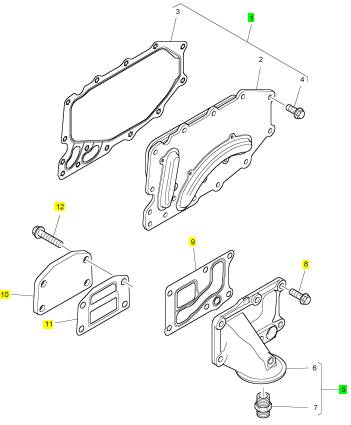

1 T408482 1 T408482 機油冷油器

5 T408200 1 T408200 濾油器座

8 2314 H034 5 2314 H034 螺旋

9 T405475 1 T405475 密封墊片

10 3623 A009 1 3623 A009 切片板

11 3688 A039 1 3688 A039 密封墊片 - 濾油器的座

12 2314 H033 4 2314 H033 螺旋

項目 零配件號碼 新件號 描述

2 1 機油冷油器

3 T408424 1 T408424 密封墊片

4 2314 H003 14 2314 H003 螺旋

項目 零配件號碼 新件號 描述

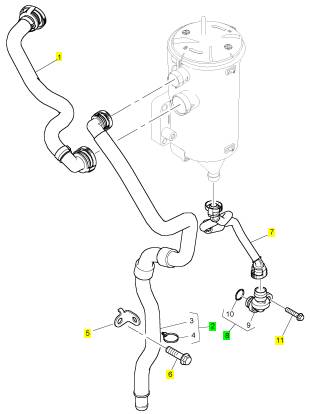

1 T405903 1 T405903 管 -呼吸者

2 T408467 1 T408467 管 -呼吸者

5 T418357 1 T418357 托架

5 T408475 1 T418357 托架

6 2314 H607 1 2314 H607 螺旋

7 T417595 1 T417595 管 -呼吸者

7 T407195 1 T417595 管 -呼吸者

8 T407957 1 T407957 停機電磁閥

11 2314 H033 1 2314 H033 螺旋

項目 零配件號碼 新件號 描述

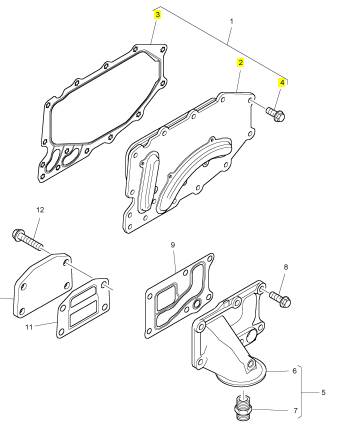

1 T411307 1 T411307 冷卻器

2 2314 H010 1 2314 H010 螺旋

3 2314 H017 1 2314 H017 螺旋

4 2314 K161 1 2314 K161 螺旋

5 T411298 1 T411298 水管 -空氣

9 2314 H004 2 2314 H004 螺旋

10 2314 H001 1 2314 H001 螺旋

11 2314 F016 2 2314 F016 螺旋

12 T411330 1 T411330 水管 -冷卻器

16 2314 H004 2 2314 H004 螺旋

17 2314 H004 2 2314 H004 螺旋

18 T417289 1 T417289 水管 -空氣

18 T411045 1 T417289 水管 -空氣

18 T414020 1 T417289 水管 -空氣

22 T411589 2 T411589 螺拴

23 T411589 2 T411589 螺拴

24 T411334 1 T411334 水管 -冷卻器

27 2314 H004 2 2314 H004 螺旋

28 2314 H004 1 2314 H004 螺旋

29 T409092 1 T409092 密封O型圈

項目 零配件號碼 新件號 描述

6 1 水管 -空氣

7 T409208 1 T409208 密封墊片

8 T409207 1 T409207 密封墊片

項目 零配件號碼 新件號 描述

1 T408882 1 T408882 托架

2 2314 J002 2 2314 J002 螺旋

3 2314 H002 2 2314 H002 螺旋

4 T419733 1 T419733 控制砂箱

4 T409881 1 檢查歷史 控制砂箱

4 T412571 1 檢查歷史 控制砂箱

5 T419731 1 T419731 線束

6 2314 F006 2 2314 F006 螺旋

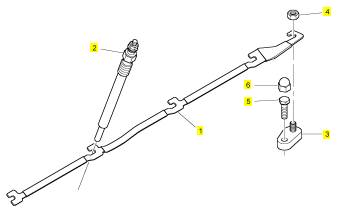

7 2817152 1 2817152 纜拉桿

8 T409393 9 T409393 纜拉桿