Perkins2206D柴油發動機配件

詳細描述

項目 零配件號碼 新件號 描述

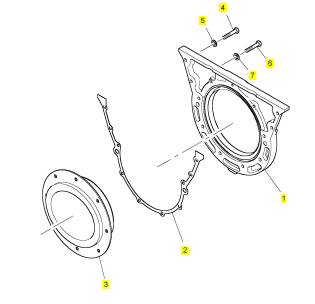

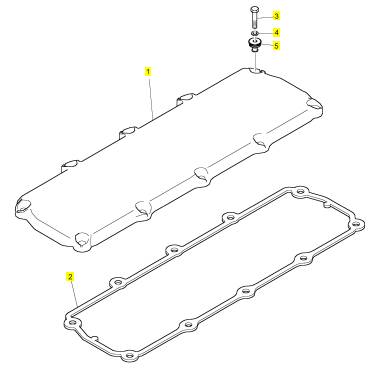

1 CH12108 1 CH12108 蓋

2 CH10166 1 CH10166 密封墊

3 T401032 1 T401032 密封墊

4 CH12110 7 CH12110 螺拴

5 CH10086 7 CH10086 墊圈

6 CH10246 6 CH10246 螺拴

7 CH10086 6 CH10086 墊圈

項目 零配件號碼 新件號 描述

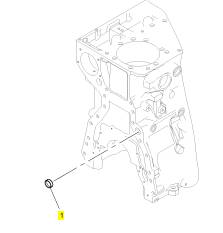

1 CH10032 1 CH10032 栓塞

項目 零配件號碼 新件號 描述

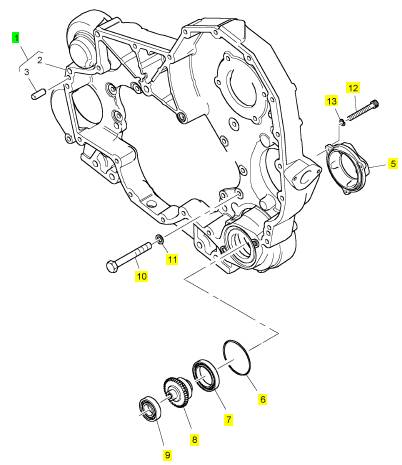

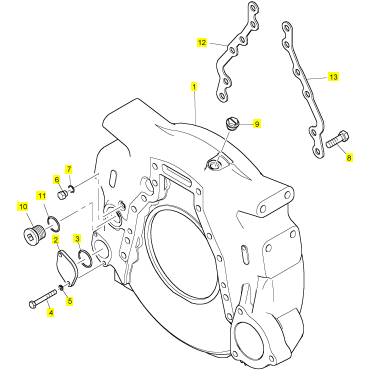

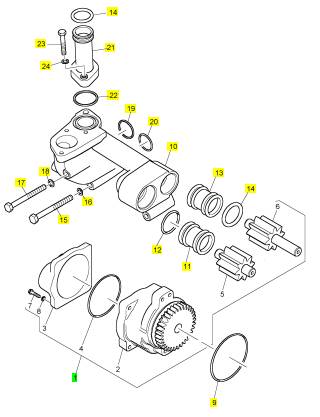

1 CH12443 1 CH12443 殼

4 CH12445 1 CH12445 密封墊 - 正時齒輪箱

5 CH12444 1 CH12444 蓋

6 CH10620 1 CH10620 密封O型圈

7 CH12439 1 CH12439 滾珠軸承

8 CH12440 1 CH12440 附加的傳動機構

9 CH12382 1 CH12382 滾珠軸承

10 CH12449 9 CH12449 螺拴

11 CH10277 9 CH10277 墊圈

12 CH12448 3 CH12448 螺拴

13 CH10277 3 CH10277 墊圈

項目 零配件號碼 新件號 描述

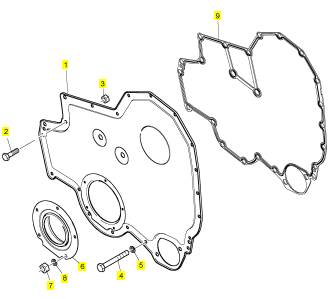

1 CH12446 1 CH12446 蓋

2 CH10041 1 CH10041 螺拴

3 CH12450 1 CH12450 螺帽

4 CH12447 17 CH12447 螺拴

5 CH10277 17 CH10277 墊圈

6 CH12442 1 CH12442 密封墊 -油

7 CH12450 4 CH12450 螺帽

8 CH12452 4 CH12452 墊圈

9 CH12441 1 CH12441 密封墊 - 正時齒輪箱蓋

項目 零配件號碼 新件號 描述

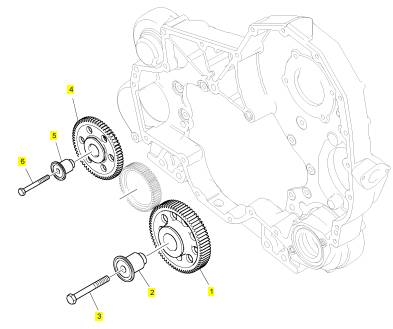

1 CH12291 1 CH12291 惰輪傳動機構

2 CH12289 1 CH12289 軸

3 CH12293 1 CH12293 螺拴

4 CH12290 1 CH12290 傳動機構

5 CH10181 1 CH10181 軸

6 CH10243 1 CH10243 螺拴

項目 零配件號碼 新件號 描述

1 CH12535 1 CH12535 飛輪殼

2 CH10165 1 CH10165 蓋

3 CH11892 1 CH11892 密封O型圈

4 CH12449 2 CH12449 螺拴

5 CH10277 2 CH10277 墊圈

6 T400249 1 T400249 栓塞

7 T409315 1 T409315 密封O型圈

8 CH12151 12 CH12151 螺拴

9 T401037 3 T401037 栓塞

10 CH10291 1 CH10291 栓塞

11 T400544 1 T400544 密封O型圈

12 CH12536 1 CH12536 間隔器

13 CH12536 1 CH12536 間隔器

項目 零配件號碼 新件號 描述

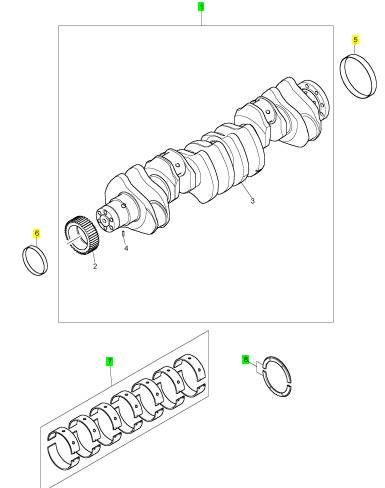

1 CH12736 1 CH12736 曲軸組合

5 CH12496 1 CH12496 套筒

6 CH12497 1 CH12497 套筒

7 KRP3120 1 KRP3120 曲軸瓦

(7) KRP3120/051 1 KRP3120/051 曲軸瓦 -U/S

8 KRP3207 1 KRP3207 止推片

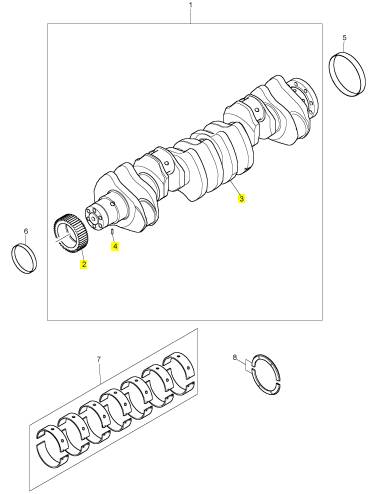

項目 零配件號碼 新件號 描述

2 CH12493 1 CH12493 曲軸傳動機構

3 1 曲軸

4 CH12495 1 CH12495 合釘 裝備

項目 零配件號碼 新件號 描述

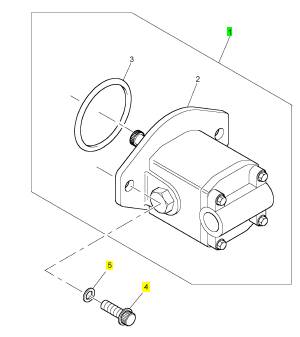

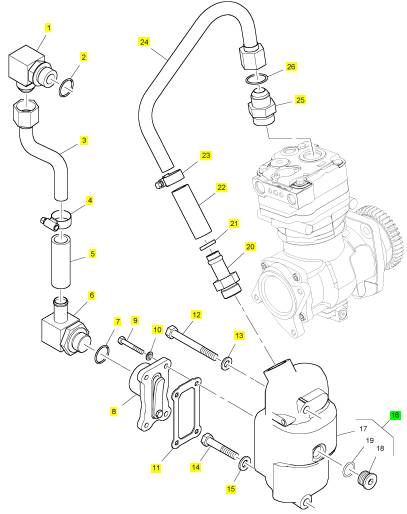

1 KRP1721 1 KRP1721 提升泵

4 CH10436 2 CH10436 螺拴

5 CH10255 2 CH10255 墊圈

項目 零配件號碼 新件號 描述

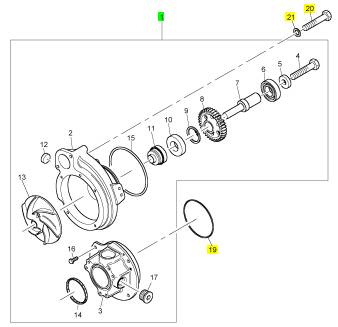

1 CH12887 1 CH12887 水泵

(1) CH12887 1 CH12887 水泵

19 CH10147 1 CH10147 密封O型圈

20 CH10248 2 CH10248 螺拴

21 CH11819 2 CH11819 墊圈

項目 零配件號碼 新件號 描述

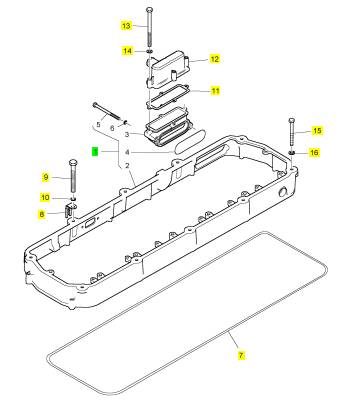

1 T400395 1 T400395 閥蓋

7 CH12459 1 CH12459 密封墊 - 搖臂室

8 CH10420 1 CH10420 接線夾

9 CH11814 7 CH11814 公制的螺拴

10 CH10277 7 CH10277 墊圈

11 CH12457 2 CH12457 密封墊 -呼吸者

12 T401637 1 T401637 呼吸者

13 CH12629 4 CH12629 螺拴

14 CH10303 4 CH10303 墊圈

15 CH10140 6 CH10140 螺拴

16 CH10277 6 CH10277 墊圈

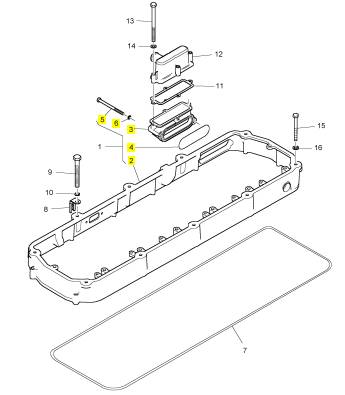

項目 零配件號碼 新件號 描述

2 1 閥蓋

3 T417055 1 T417055 承接器

4 T400396 1 T400396 密封O型圈

5 T400397 2 T400397 螺拴

6 CH10277 2 CH10277 墊圈

項目 零配件號碼 新件號 描述

1 T401038 1 T401038 汽缸蓋蓋

2 CH12142 1 CH12142 密封墊

3 CH12143 10 CH12143 螺拴

4 CH11894 10 CH11894 墊圈

5 CH12140 10 CH12140 密封墊

項目 零配件號碼 新件號 描述

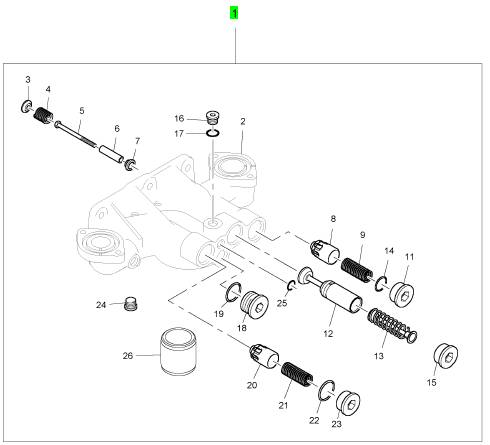

1 CH12314 1 CH12314 油泵

(1) CH12314 1 CH12314 油泵

9 CH10126 1 CH10126 密封O型圈

10 CH12316 1 CH12316 油肘管

11 CH10169 1 CH10169 聯結器

12 CH11906 2 CH11906 密封O型圈

13 CH10170 2 CH10170 聯結器

14 CH10135 2 CH10135 密封O型圈

15 CH12323 1 CH12323 螺拴

16 CH10277 1 CH10277 墊圈

17 CH10140 5 CH10140 螺拴

18 CH10277 5 CH10277 墊圈

19 CH12318 1 CH12318 密封O型圈

20 CH10228 1 CH10228 密封O型圈

21 T401160 1 T401160 油填隙料

22 T400368 1 T400368 密封O型圈

23 CH12447 2 CH12447 螺拴

24 CH10277 2 CH10277 墊圈

25 CH10135 1 CH10135 密封O型圈

項目 零配件號碼 新件號 描述

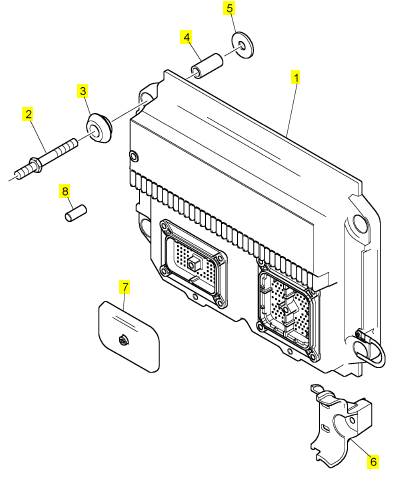

1 CH12895 1 CH12895 引擎控制組件ECM

2 CH10297 4 CH10297 圖釘

3 CH10272 8 CH10272

4 CH10108 4 CH10108 間隔器

5 CH10279 8 CH10279 墊圈

6 CH11932 2 CH11932 托架

7 CH12655 1 CH12655 蓋

8 CH12370 4 CH12370 帽

項目 零配件號碼 新件號 描述

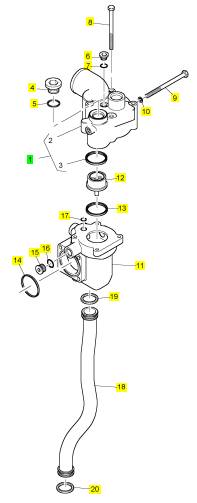

1 T401652 1 T401652 節溫器殼

4 CH12474 2 CH12474 栓塞

5 CH11621 2 CH11621 密封O型圈

6 CH10285 1 CH10285 栓塞

7 CH10161 1 CH10161 密封O型圈

8 CH12171 4 CH12171 螺拴

9 CH12175 4 CH12175 螺拴

10 CH10277 4 CH10277 墊圈

11 CH12167 1 CH12167 調整器

12 CH11620 1 CH11620 節溫器

13 CH12166 1 CH12166 密封墊 - 節溫器殼

14 CH12165 1 CH12165 密封墊 - 節溫器殼

15 CH10287 3 CH10287 栓塞

16 CH10146 3 CH10146 密封O型圈

17 CH12661 1 CH12661 密封O型圈

18 CH12168 1 CH12168 管

19 CH10201 1 CH10201 密封O型圈

20 CH10201 1 CH10201 密封O型圈

項目 零配件號碼 新件號 描述

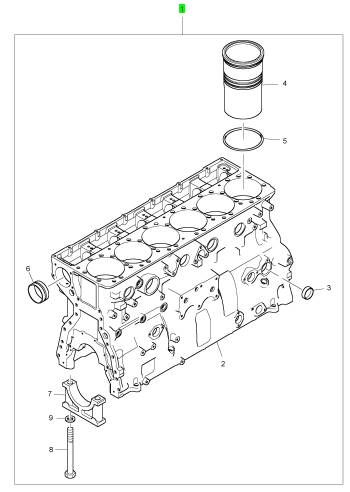

1 CH12684 1 CH12684 缸體組合

項目 零配件號碼 新件號 描述

1 CH12481 1 CH12481 軸

4 CH12484 1 CH12484 搖臂座

5 CH12483 2 CH12483 軸環

6 T400226 1 T400226 搖臂

7 CH12511 1 CH12511 搖臂

8 CH12509 1 CH12509 螺帽

9 CH12512 1 CH12512 螺旋

10 CH10229 1 CH10229 密封O型圈

11 CH12702 1 CH12702 樞

12 CH12514 1 CH12514 搖臂

13 CH12513 2 CH12513 螺旋

14 CH11865 2 CH11865 螺帽

15 CH12278 12 CH12278 結軸塊

16 CH12795 12 CH12795 PUSHROD

17 CH12808 6 CH12808 PUSHROD

項目 零配件號碼 新件號 描述

2 1 軸

3 CH12505 2 CH12505 栓塞

項目 零配件號碼 新件號 描述

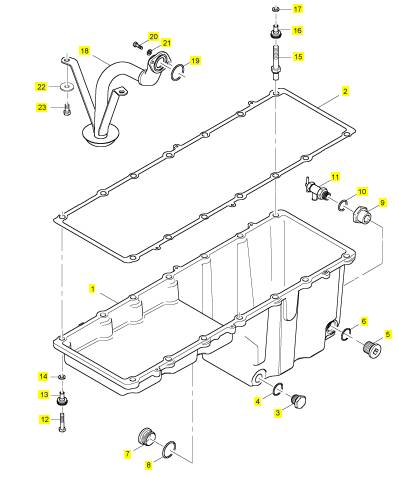

1 CH12117 1 CH12117 油底殼

2 CH12118 1 CH12118 密封墊 -油底殼

3 CH11571 1 CH11571 排泄栓塞

4 CH11573 1 CH11573 密封O型圈

5 T400251 1 T400251 栓塞

6 T400544 1 T400544 密封O型圈

7 T400251 1 T400251 栓塞

8 T400544 1 T400544 密封O型圈

9 T401275 1 T401275 承接器

10 T406205 1 T406205 密封O型圈

11 2461 A503 1 2461 A503 關閉閥

12 CH12124 13 CH12124 螺拴

13 CH12119 13 CH12119 密封墊

14 CH10113 13 CH10113 墊圈

15 CH12657 1 CH12657 圖釘

16 CH12119 1 CH12119 密封墊

17 CH10113 1 CH10113 墊圈

18 T400250 1 T400250 管 - 油的吸入

19 CH10098 1 CH10098 密封O型圈

20 CH10041 2 CH10041 螺拴

21 T401636 2 T401636 墊圈

22 CH10099 2 CH10099 墊圈

23 CH12122 2 CH12122 螺拴

項目 零配件號碼 新件號 描述

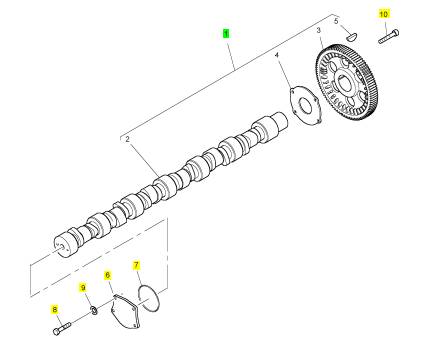

1 CH12436 1 CH12436 凸輪軸

6 CH12435 1 CH12435 蓋

7 CH12437 1 CH12437 密封O型圈

8 CH11815 4 CH11815 螺拴

9 CH10277 4 CH10277 墊圈

10 CH12438 4 CH12438 螺拴

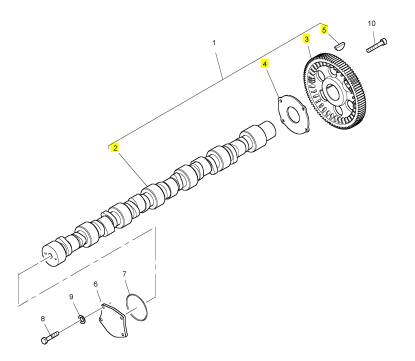

項目 零配件號碼 新件號 描述

2 1 凸輪軸

3 CH12520 1 CH12520 凸輪軸傳動機構

4 CH12519 1 CH12519 推力墊圈

5 CH10005 1 CH10005 半圓鍵

項目 零配件號碼 新件號 描述

1 T401701 1 T401701 燃油濾清器

項目 零配件號碼 新件號 描述

1 T401729 1 T401729 承接器

2 T400248 1 T400248 密封O型圈

3 T401731 1 T401731 管

4 T401735 2 T401735 搖臂座

5 T401734 1 T401734 水管

6 T401730 1 T401730 承接器

7 T400248 1 T400248 密封O型圈

8 T401725 1 T401725 閥

9 T401736 4 T401736 螺拴

10 CH10303 4 CH10303 墊圈

11 T401724 1 T401724 密封墊

12 T401732 1 T401732 螺拴

13 CH11819 1 CH11819 墊圈

14 T401737 1 T401737 螺拴

15 CH11819 1 CH11819 墊圈

16 T401723 1 T401723 管集箱箱

20 T401726 1 T401726 連接器

21 T400248 1 T400248 密封O型圈

22 T401733 1 T401733 水管

23 T401735 2 T401735 搖臂座

24 T401728 1 T401728 管

25 T401727 1 T401727 承接器

26 T401291 1 T401291 密封O型圈

項目 零配件號碼 新件號 描述

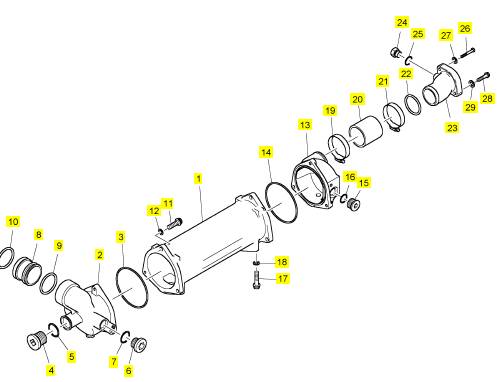

1 T400172 1 T400172 機油冷卻器

2 T400162 1 T400162 端帽

3 T400173 1 T400173 密封O型圈

4 CH10291 1 CH10291 栓塞

5 CH12240 1 CH12240 密封O型圈

6 CH12474 1 CH12474 栓塞

7 CH11621 1 CH11621 密封O型圈

8 CH10395 1 CH10395 聯結器

9 CH12238 1 CH12238 密封O型圈

10 CH12238 1 CH12238 密封O型圈

11 CH11565 6 CH11565 螺拴

12 CH10277 6 CH10277 墊圈

13 T400175 1 T400175 端帽

14 T400173 1 T400173 密封O型圈

15 CH11375 1 CH11375 栓塞

16 CH10119 1 CH10119 密封O型圈

17 CH12447 4 CH12447 螺拴

18 CH10277 4 CH10277 墊圈

19 T400174 1 T400174 搖臂座

20 CH12662 1 CH12662 水管

21 T400174 1 T400174 搖臂座

22 CH12231 1 CH12231 密封O型圈

23 T401049 1 T401049 水肘管

24 CH10285 1 CH10285 栓塞

25 CH10161 1 CH10161 密封O型圈

26 CH10140 1 CH10140 螺拴

27 CH10277 1 CH10277 墊圈

28 CH12447 1 CH12447 螺拴

29 CH10277 1 CH10277 墊圈

d. Seat the sensor and tighten the bolt.

If the sensor will not seat, repair the sensor

or replace the sens or, as required.

Note: Do not remove the sensor from the bracket.

e. Ensure that the sensor is properly oriented

and that the harness is secured in the proper

location.

2. Verify that the repair eliminates the fault.

STOP.

Test Step 5. Install the Bypass Harness

for the Position Sensors

A. Turn the keyswitch to the OFF position.

B. Disconnect the J2/P2 ECM connector.

C. Use the following procedure for the crankshaft

position sensor:

a. Fabricate a harness from two wires. The wires

must reach between the crankshaft position

sensor and the P2 connector. Twisted pair

wiring is required. Ensure that the wires have

at least one twist per inch.

b. Connect one wire of the harness between

P2-35 and P401-2.

c. Connect the other wire between P2-25 and

P401-1.

D. Use the following procedure for the camshaft

position sensor:

a. Fabricate a harnes s from two wires. The wires

must reach between the camshaft position

sensor and the P2 connector. Twisted pair

wiring is required. Ensure that the wires have

at least one twist per inch.

b. Connect one wire of the harness between

P2-46 and P402-2.

c. Connect one wire of the harness between

P2-47 and P402-1.

E. Reconnect the P2 connector.

F. Attempt to start the engine. Verify that the original

fault is eliminated.

Expected Result:

The fault is eliminated with the installation of the

bypass harness.

Results:

• OK

Repair: Permanently install a new section of

harness.

STOP.

• Not OK

Repair: Verify that the correct terminals have been

installed in the correct location on the P2 ECM

connector. If the temporary harness was installed

correctly, remove the temporary harness. Connect

the original wiring.

Proceed to Test Step 6.

Test Step 6. Check the ECM

A. Turn the keyswitch to the OFF position.

B. Temporarily connect a test ECM.

C. Start the engine. Run the engine in order to repeat

the conditions when the fault occurs.

D. If the fault is eliminated with the test ECM,

reconnect the suspect ECM.

E. If the fault returns with the suspect ECM, replace

the ECM.

Verify that the repair eliminates the fault.

Expected Result:

The fault remains with the suspect ECM.

Results:

• OK

Repair: If the fault is eliminated with the test ECM

and the fault returns with the suspect ECM, replace

the ECM.

Verify that the repair eliminates the fault.

STOP.

• Not OK

Repair: Replace the sensor.

Verify that the repair eliminates the fault.

STOP.

This document has been printed from SPI². Not for Resale

![]() 110

110

Troubleshooting Section

KENR6224

Engine

Temperature

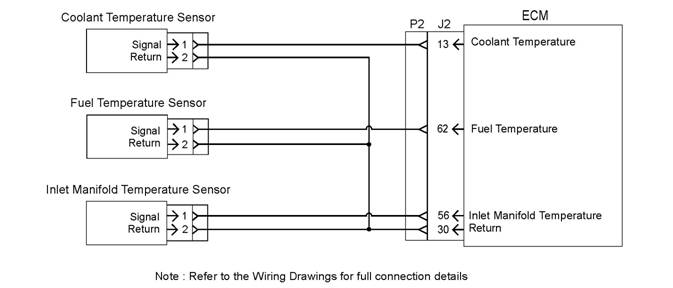

i02569910

Sensor

If the sensor is disconnected at the sensor connector,

the presenc e of pull-up voltage at the sensor

connector indicates that the wires from the sensor

connector to the ECM are not open or shorted to

Open or Short Circuit - Test

System Operation Description:

Use this procedure to troubleshoot any suspect faults

with the following sensors:

• Intake manifold air temperature sensor

• Coolant temperature sensor

• Fuel temperature sensor

This procedure covers the following diagnostic codes :

• 0110-03 Engine Coolant Temperature Sensor

voltage above normal

• 0110-04 Engine Coolant Temperature Sensor

voltage below normal

• 0172-03 Intake Manifold Air Temperatu, re Sensor

voltage above normal

• 0172-04 Intake Manifold Air Temperature Sensor

voltage below normal

• 0174-03 Fuel Temperature Sensor voltage above

normal

• 0174-04 Fuel Temperature Sensor voltage below

normal

The troubleshooting procedures for the diagnostic

codes of each temperature sensor are identical.

The temperature sensors are passiv e sensors that

have two terminals. The temperature sens ors do not

require supply voltage from the Electronic Control

Module (ECM).

Pull-up Voltage

The ECM continuously outputs a pull-up voltage

on the circuit for the sensor signal wire. The ECM

uses this pull-up voltage in order to detect an open

in the signal circuit. When the ECM detects the

presence of a voltage that is above a threshold on the

signal circuit, the ECM will generate an open circuit

diagnostic code (03) for the sens or.

ground. If the sensor is disconnected at the sensor

connector, the absence of pull-up voltage at the

sensor connec tor indicates an open in the signal wire

or a short to ground. If the sensor is disconnected at

the sensor connector and the voltage at the sensor

connector is different from pull-up voltage, the signal

wire is shorted to another wire in the harness.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

111

Troubleshooting Section

|

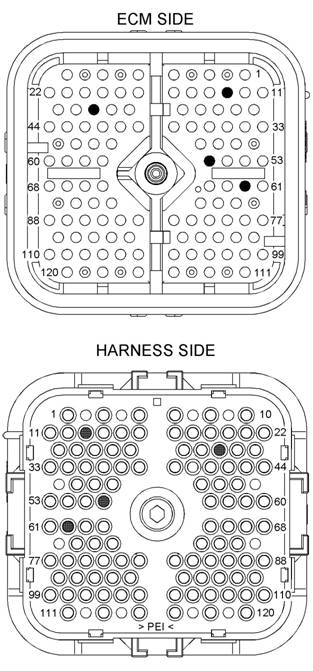

Schematic for the engine temperature sensors

Connectors and the Wiring

A. Turn the keyswitch to the OFF position.

g01287472

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 112

112

Troubleshooting Section

KENR6224

Illustration 44

P2 ECM connector

(P2-13) Engine coolant temperature

(P2-30) Return

(P2-56) Intake manifold air temperature

(P2-62) Fuel temperature

g01146245

|

wires that are associated with the temperature

sensors.

D. Check the allen head screw on each ECM

connector for the proper torque. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for the correct torque values.

E. Check the harness and wiring for abrasions and

for pinch points from each sensor to the ECM.

Expected Result:

All connectors, pins, and sockets are completely

coupled and/or inserted. The harness and wiring are

free of corrosion, of abrasion, and of pinc h points .

Results:

• OK – The connectors and wiring are OK. Proceed

to Test Step 2.

• Not OK – There is a fault in the connectors and/or

wiring.

Repair: Repair the connectors or wiring and/or

replace the connectors or wiring. Ensure that all of

the seals are properly in place and ensure that the

connectors are completely coupled.

Verify that the repair eliminates the fault.

STOP.

Codes

A. Connect the electronic service tool to the

diagnostic connector.

B. Turn the keyswitch to the ON position.

C. Monitor the active diagnostic code screen on the

electronic service tool. Check and record any

active diagnostic codes.

Note: Wait at least 15 seconds in order for the

diagnostic codes to bec ome ac tive.

D. Look for an 03 diagnostic code or an 04 diagnostic

code.

Expected Result:

B. Thoroughly inspect the ECM connectors and the

connectors for the suspect sensor. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for details.

|

Results:

•

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

113

Troubleshooting Section

•

•

Repair: The fault may have been related to

a faulty connection in the harness. Carefully

reinspect the connectors and wiring. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for additional information.

STOP.

Not OK – An 03 diagnostic code is active at this

time. Proceed to Test Step 3.

Not OK – An 04 diagnostic code is active at this

time. Proceed to Test Step 6.

E. Turn the keyswitch to the OFF position.

F. Reconnect the P2 connector.

Expected Result:

Each check of the resistance is greater than 20,000

Ohms.

Results:

• OK – Each check of the resistance is greater than

20,000 Ohms. Proceed to Test Step 5.

|

A. Disconnect the suspect sensor at the sensor

connector.

B. Turn the keyswitch to the ON position.

C. Measure the voltage between terminal C (signal)

and terminal B (return) at the s ensor connector.

•

Not OK – At least one check of the resistanc e is

less than 20,000 Ohms.

Repair: The low resistance measurement indicates

a short circuit between two or more wires. Repair

the connectors or wiring and/or replace the

connectors or wiring.

STOP.

|

|

Expected Result:

The voltage is 5.5 ± 0.5 VDC.

Results:

pull-up voltage is present at the suspect sensor

connector.

Repair: The open circuit is in the sensor or the

wire between the sensor and the sensor connector.

Replace the sensor. Do not install the sensor in

the engine. Verify that no diagnostic codes are

active for the sus pect sensor before permanently

installing the sensor.

STOP.

Proceed to Test Step 4.

Test Step 4. Check the Signal Wire for a

Short Circuit

A. Turn the keyswitch to the OFF position.

B. Disconnect the P2 connector.

C. Measure the resistance between the terminal

for the sensor signal wire at the ECM and the

remaining terminals on the P2 connector.

D. Measure the resis tance between the terminal for

the sensor signal wire at the ECM and engine

ground.

|

A. Turn the keyswitch to the OFF position.

B. Install a jumper wire between terminal B and

terminal C on the connector for the suspect

sensor. Connect the jumper on the harness side

of the connector.

C. Turn the keyswitch to the ON position.

D. Wait at least 15 seconds for activation of the 04

diagnostic code.

Note: Monitor the “Active Diagnostic Codes” screen

on the electronic service tool before installing the

jumper wire and after installing the jumper wire.

E. Remove the jumper wire. Check for an 04

diagnostic code again.

F. Turn the keyswitch to the OFF position.

Expected Result:

An 04 diagnostic code is active when the jumper wire

is installed. An 03 diagnostic code is active when the

jumper wire is removed.

Results:

• OK – The engine harness and the ECM are okay.

This document has been printed from SPI². Not for Resale

![]() 114

114

Troubleshooting Section

KENR6224

•

Repair: Temporarily connect a new sensor to the

harness, but do not install the new sensor in the

engine. Verify that there are no active diagnostic

codes for the sensor. If there are no active

diagnostic codes for the sensor, permanently

install the new sensor. Clear any logged diagnostic

codes.

STOP.

Not OK – The 03 diagnostic code remains active

with the jumper in place. There is an open circuit

between the ECM and the sensor connector.

Proceed to Test Step 7.

|

A. Turn the keyswitch to the OFF position.

B. Check the operation of the ECM by creating an

open circuit at the ECM.

a. Remove the signal wire for the suspect s ensor

from the P2connector.

b. Remove the sensor return from terminal P2-30.

Note: Disconnecting the sensor return from the ECM

will generate an 03 diagnostic code for all sensors

|

|

A. Turn the keyswitch to the OFF position.

B. Disconnect the sus pect sensor from the harness

at the sensor connec tor.

C. Turn the keyswitch to the ON pos ition. Wait at

least 15 sec onds for activation of the diagnostic

codes.

D. Access the “Active Diagnostic Codes” screen on

the electronic service tool and check for an active

03 diagnostic code for the suspect sensor.

E. Turn the keyswitch to the OFF position.

Expected Result:

An 03 diagnostic code is now active for the suspect

sensor.

Results:

disconnecting the sensor. An 03 diagnostic code

bec ame active after the sensor was disconnected.

Repair: Temporarily connect a new sensor to the

harness, but do not install the new sensor in the

engine. Verify that there are no active diagnostic

codes for the sensor. If there are no active

diagnostic codes for the sensor, permanently

install the new sensor. Clear any logged diagnostic

codes.

Verify that the repair eliminates the fault.

STOP.

• Not OK – The 04 diagnostic code is still present.

Leave the sensor disconnected. Proceed to Test

Step 7.

|

the original diagnostic code. Delete the logged

diagnostic codes when you are finished.

c. Turn the keyswitch to the ON position. Monitor

the “Active Diagnostic Code” screen on the

electronic service tool. Wait at least 15 seconds

for activation of the code.

An 03 diagnostic code s hould be active for the

suspect sensor.

C. Check the operation of the ECM by creating a

short at the ECM.

a. Install a wire jumper between the terminals for

the sensor signal and the sensor return.

b. Monitor the “Active Diagnostic Code” screen

on the electronic service tool. Wait at least 15

seconds for activation of the code.

An 04 diagnostic code should be active when

the wire jumper is installed.

c. Remove the wire jumper and reconnect all

wires.

Expected Result:

An 03 diagnostic code is active when the sensor

signal wire is removed from the ECM connector. An

04 diagnos tic c ode is active when the signal wire is

connected to the sensor return.

Results:

in the wiring between the ECM and the sensor

connector.

Repair: If the code is active for more than one

sens or, the fault is most likely in the return wire for

the sensor. Repair the return wire for the sensor

or replace the harness.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

115

Troubleshooting Section

•

If the code is only active for one sensor, the fault is

most likely in the signal wire for the sensor. Repair

the signal wire for the sensor.

STOP.

Not OK – One of the following conditions exists:

The 03 diagnostic code is not active when the

sensor signal wire is disconnected. The 04

diagnostic code is not active when the wire jumper

is installed.

Repair: Replace the ECM. Refer to the

Troubleshooting Guide, “Replacing the ECM”.

Verify that the fault is eliminated.

STOP.

The “Oil Pressure” lamp indicates low engine oil

pressure. The severity of the fault is indicated by the

“Warning”, “Action Alert” or “Shutdown” lamps.

The “Action Alert” output indicates an engine fault

that is suffic iently severe so that the engine should be

shut down. The “Action Alert” output would normally

be used by the operator in order to open the circuit

breaker for the generator and the output would be

used to stop the engine.

Indicator Lamp

i02570763

Circuit - Test

System Operation Description:

The ECM has sev en available outputs that indicate

the operating status of the engine:

• Overspeed

• Coolant temperature

• Oil pressure

• Diagnostics

• Warning

• Action alert

• Shutdown

The outputs can be used to drive indicator lamps or

other controls. Each output provides a connection to

either the battery positive terminal or to the battery

negative terminal at a maximum current of 0.3 amp

when the output is ON. Each output gives an open

circuit when the output is OFF.

The “Diagnostics” output indicates that a fault exists

on the electronic system rather than with the engine.

The electronic s ervice tool should be used to

diagnose the fault.

The “Overspeed” output indicates that an overspeed

fault exists. The severity of the fault is indicated by

the “Warning”, “Action Alert” or “Shutdown” lamps.

The “Coolant Temperature” lamp indicates a high

coolant temperature fault. The severity of the fault

is indicated by the “Warning”, “Action Alert” or

“Shutdown” lamps.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 116

116

Troubleshooting Section

KENR6224

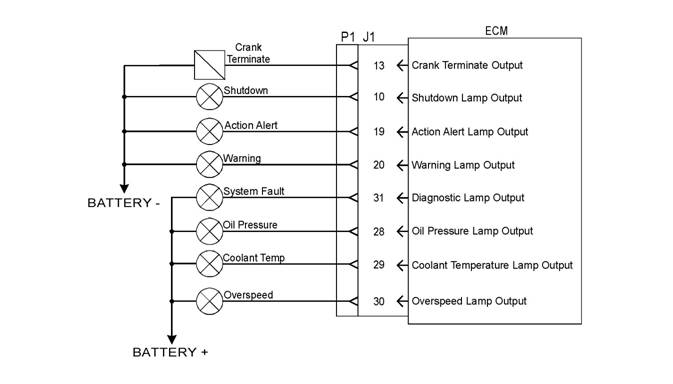

Illustration 45

Schematic diagram for the indicator outputs

Note: Outputs from the ECM can be used to operate

lamps or relays.

g01287870

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() KENR6224

KENR6224

117

Troubleshooting Section

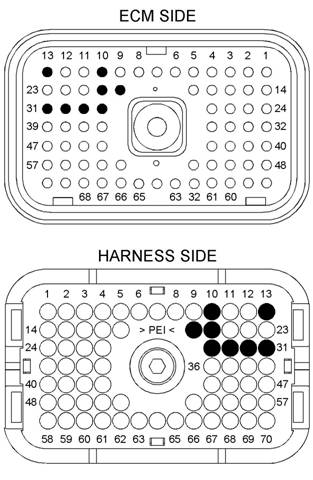

Illustration 46

Connections on the P1/J1 connector

(10) Shutdown lamp

(13) Engine running output

(19) Action alert lamp

g01287923

Illustration 47

Connections on the OEM connector

(3) Diagnostics lamp

(4) Warning lamp

(5) Action alert lamp

(8) Oil pressure lamp

(9) Overspeed lamp

(11) Engine running output

(16) Shutdown lamp

(17) Coolant temperature lamp

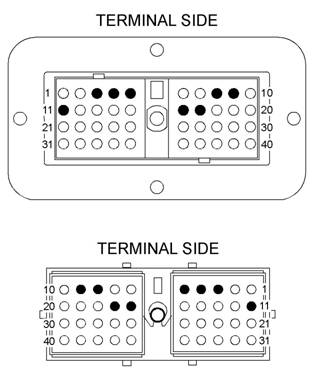

Test Step 1. Inspect the

Electrical

g01287960

(20) Warning lamp

(28) Oil pressure lamp

(29) Coolant temperature lamp

Connectors

and the Wiring

(30) Overspeed lamp

(31) Diagnostics lamp

A. Replace any indicator lamps that are blown.

B. Check the wiring in order to determine if status

indicators are present. Check that the status

indicators are controlled by the ECM. Refer to 45.

Some indicators may obtain engine status through

a data link.

Note: If status indicators are not directly controlled

by the ECM, stop this test.

C. Thoroughly inspect connector J1/P1, the wiring for

the indicator circuit and the connectors. Refer to

the Troubleshooting Guide, “Electrical Connectors

- Inspect”.

D. Perform a 45 N (10 lb) pull test on each wire that

is ass ociated with the status indicators.

E. Check that the Allen head screw that secures

the ECM connec tor is correctly tightened to a

maximum torque of 3 N·m (26.5 lb in).

This document has been printed from SPI². Not for Resale

![]() 118

118

Troubleshooting Section

KENR6224

F.

Check the harness and wiring from the status

indicators to the ECM for abrasion and pinch

points. All connectors, pins and sockets should be

completely mated or inserted. The harness and

the wiring should be free of corrosion, abras ion or

pinch points.

B. Turn the keyswitch to the OFF position.

C. Disconnect the ECM connector J1/P1.

D. Turn the keyswitch to the ON position.

E. Connect the jumper wire between the following

|

|

|

The lamps turn on and the lamps turn off per the

above description.

Results:

• OK – The connectors and wiring are OK. Proceed

to Test Step 2.

• Not OK – There is a fault in the connectors and/or

wiring.

Repair: Repair the connectors or wiring and/or

replace the connectors or wiring. Ensure that all of

the seals are properly in place and ensure that the

connectors are completely coupled.

Verify that the repair eliminates the fault.

STOP.

Short Circuit

A. Disconnect the control wire at the suspect

indicator lamp or the relay.

B. Attempt to start the engine and check the status

indicators .

Expected Result:

The short circuit has been eliminated.

Results:

• OK – - The short circuit is no longer present.

Repair: Repair the indicator or replace the

indicator.

STOP.

indicator. Proceed to Test Step 3.

with a Jumper Wire

A. Fabric ate a jumper wire that is 100 mm (4.0 inch)

in length with a Deutsch connector socket on both

ends.

|

lamp.

• Pin 10 and Battery +

• Pin 13 and Battery +

• Pin 19 and Battery +

• Pin 20 and Battery +

• Pin 28 and Battery -

• Pin 29 and Battery -

• Pin 30 and Battery -

• Pin 31 and Battery -

Expected Result:

Each lamp should illuminate only when the jumper is

inserted on the applicable pins in the ECM connector

P1.

Results:

• OK – The harness and indicators operate correctly.

Repair: Reconnect all connectors and recheck

the operation of the indicators. If the fault returns,

replace the ECM.

STOP.

• Not OK – There is a fault in the indic ator circuit.

Repair: Recheck electrical connections and the

wiring for damage, corrosion, or abrasion. Repair

the connectors and the wiring or replace the

connectors and the wiring.

Proceed to Test Step 4.

Circuit

A. Turn the keyswitch to the OFF position.

B. Remove the control wire for the suspect indicator

from the ECM connector P1. Refer to the

Troubleshooting Guide.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

119

Troubleshooting Section

C. Attempt to start the engine and chec k the status

indicators .

Expected Result:

All other indicator lamps operate c orrectly. The

suspect indicator lamp remains off.

Results:

• OK – The short is in the harness.

Repair: Repair the harness or replace the harness .

Verify that the fault is eliminated.

STOP.

• Not OK – The short circuit is present when the

circuit is disconnected from the ECM.

Repair: Dis connect the ECM connector J1/P1

and check for damage or corrosion. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect”.

If the fault is not eliminated, replace the ECM.

Refer to the Troubleshooting Guide, “Replacing

the ECM”.

STOP.

i02570748

Injector Solenoid Circuit - Test

System Operation Description:

Use this procedure to troubleshoot any suspect faults

with the injector solenoids.

Use this procedure for the following diagnostic codes:

• 0001-11 Cylinder #1 Injector other failure mode

• 0002-11 Cylinder #2 Injector other failure mode

• 0003-11 Cylinder #3 Injector other failure mode

• 0004-11 Cylinder #4 Injector other failure mode

• 0005-11 Cylinder #5 Injector other failure mode

• 0006-11 Cylinder #6 Injector other failure mode

• You have been directed to this procedure from the

Troubleshooting Guide, “Troubleshooting without a

Diagnostic Code”.

Perform this procedure under conditions that are

identical to the conditions that exist when the fault

occurs. Typically, faults with an injector solenoid

occur when the engine is warm and/or when the

engine is under vibration (heavy loads).

These engines have Electronic Unit Injectors (EUI)

that are mechanically actuated and electronically

controlled. The Engine Control Module (ECM) sends

a 105 volt pulse to each injector solenoid. The pulse

is sent at the proper time and for the correct duration

for a given engine load and speed. The solenoid

is mounted on top of the fuel injector body. The

105 volt pulse can be individually cut out to aid in

troubleshooting faults that involve misfires.

If an open circuit is detected in the solenoid circuit,

a diagnostic code is generated. The ECM continues

to try to fire the injector. If a short is detected, a

diagnostic code is generated. The ECM will disable

the s olenoid circ uit. The ECM will periodically try

to fire the injector. If the short circuit remains this

sequence of events will be repeated until the fault

is corrected.

An injector trim file must be programmed into the

ECM for each cylinder. Refer to the Troubleshooting

Guide, “Injector Trim File”.

Cylinder Cutout Test

The “Cylinder Cutout Test” is used in order to

determine the individual cylinder performance while

the engine is running. As one or more cylinders are

cut out during the test, the “Fuel Position” of each

injector is used in order to evaluate the performance

of the remaining cy linders that are firing. As the

different cylinders are cut out, a comparison of

the change in “Fuel Position” is used to identify

cylinders that are weak or misfiring. One reason for a

cylinder that is weak or misfiring is an injector that is

malfunctioning mechanically.

During the test, when a good injector is cut out, the

“Fuel Position” of the remaining injectors will increase.

This increase in the “Fuel Position” is caused by the

remaining injectors that are compensating for the cut

out injector. If a malfunctioning injector is cut out, the

“Fuel Position” for the remaining injectors will not

change. This is the result of the smaller quantity of

fuel that is needed to compensate for the power loss

from the malfunctioning injector. The “Cylinder Cutout

Test” is used to isolate a malfunctioning injector in

order to avoid replacement of injectors that are in

good repair.

Note: Prior to running the “Cylinder Cutout Test”, all

active diagnostic codes must be corrected.

Injector Solenoid Test

This document has been printed from SPI². Not for Resale