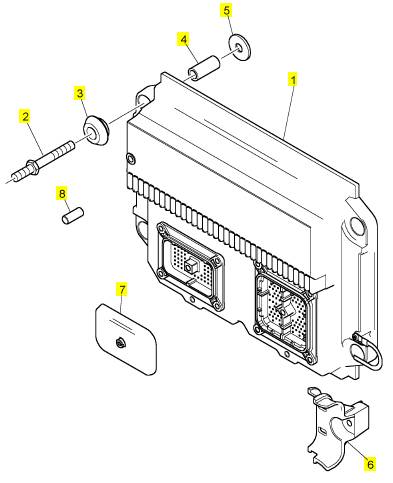

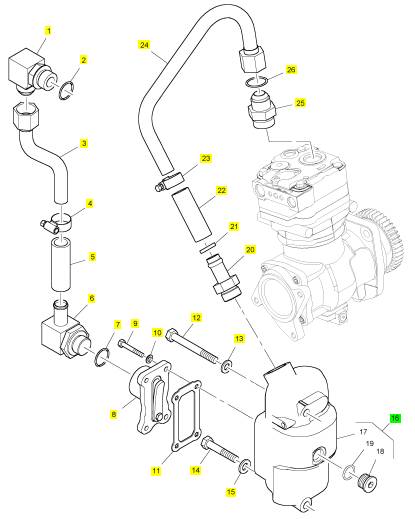

Perkins2206D柴油發動機CH12895引擎控制組件ECM

詳細描述

項目 零配件號碼 新件號 描述

1 CH12895 1 CH12895 引擎控制組件ECM

2 CH10297 4 CH10297 圖釘

3 CH10272 8 CH10272

4 CH10108 4 CH10108 間隔器

5 CH10279 8 CH10279 墊圈

6 CH11932 2 CH11932 托架

7 CH12655 1 CH12655 蓋

8 CH12370 4 CH12370 帽

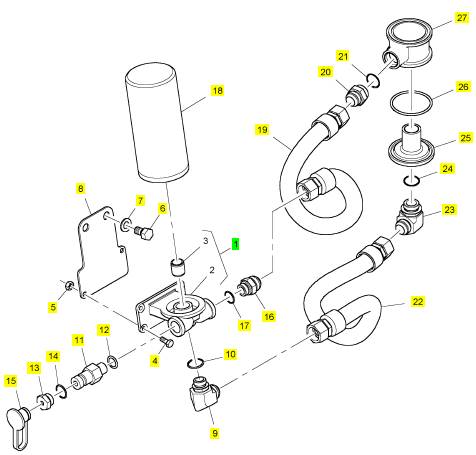

項目 零配件號碼 新件號 描述

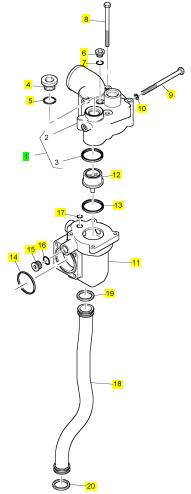

1 T401652 1 T401652 節溫器殼

4 CH12474 2 CH12474 栓塞

5 CH11621 2 CH11621 密封O型圈

6 CH10285 1 CH10285 栓塞

7 CH10161 1 CH10161 密封O型圈

8 CH12171 4 CH12171 螺拴

9 CH12175 4 CH12175 螺拴

10 CH10277 4 CH10277 墊圈

11 CH12167 1 CH12167 調整器

12 CH11620 1 CH11620 節溫器

13 CH12166 1 CH12166 密封墊 - 節溫器殼

14 CH12165 1 CH12165 密封墊 - 節溫器殼

15 CH10287 3 CH10287 栓塞

16 CH10146 3 CH10146 密封O型圈

17 CH12661 1 CH12661 密封O型圈

18 CH12168 1 CH12168 管

19 CH10201 1 CH10201 密封O型圈

20 CH10201 1 CH10201 密封O型圈

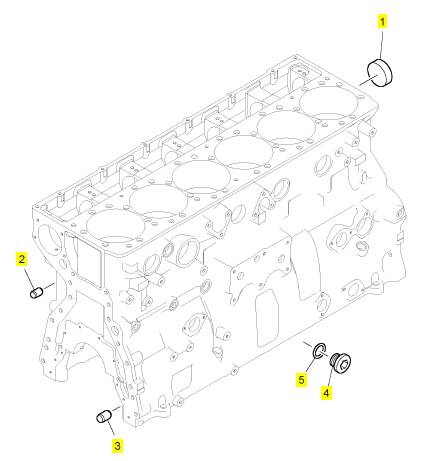

項目 零配件號碼 新件號 描述

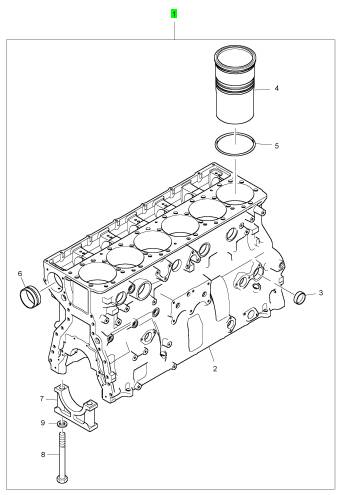

1 CH12684 1 CH12684 缸體組合 - O 圈

項目 零配件號碼 新件號 描述

2 1 缸體

3 CH11752 5 CH11752 栓塞

4 CH12489 6 CH12489 缸套 - 壓八配合

5 CH12488 6 T400359 密封墊 -油

6 CH12630 7 CH12630 凸輪軸襯套

7 7 軸承蓋

8 CH12631 14 CH12631 螺拴

9 CH12632 14 CH12632 墊圈

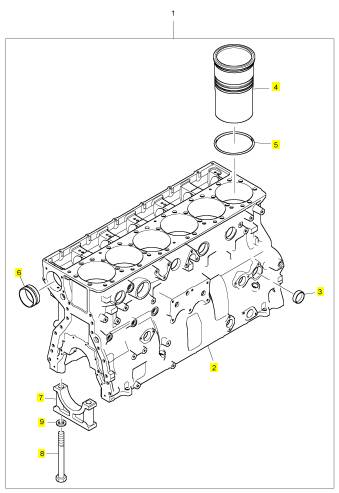

項目 零配件號碼 新件號 描述

1 CH10032 3 CH10032 栓塞

2 CH11713 2 CH11713 合釘

3 CH11714 6 CH11714 合釘

4 T400363 3 T400363 栓塞

5 T409314 3 T409314 密封O型圈

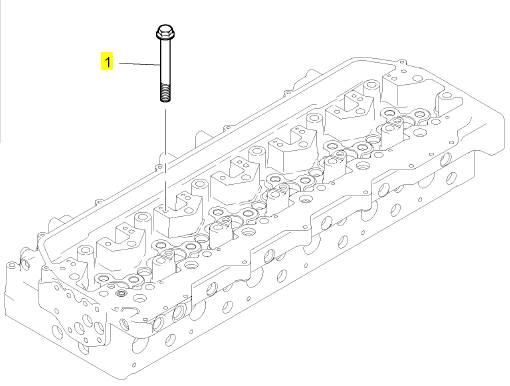

項目 零配件號碼 新件號 描述

1 CH12287 6 CH12287 螺拴

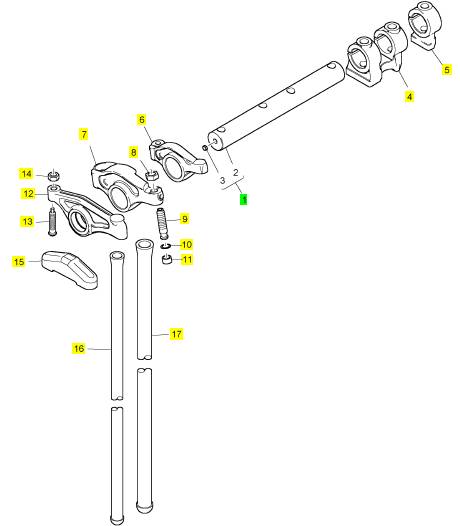

項目 零配件號碼 新件號 描述

1 CH12481 1 CH12481 軸

4 CH12484 1 CH12484 搖臂座

5 CH12483 2 CH12483 軸環

6 T400226 1 T400226 搖臂

7 CH12511 1 CH12511 搖臂

8 CH12509 1 CH12509 螺帽

9 CH12512 1 CH12512 螺旋

10 CH10229 1 CH10229 密封O型圈

11 CH12702 1 CH12702 樞

12 CH12514 1 CH12514 搖臂

13 CH12513 2 CH12513 螺旋

14 CH11865 2 CH11865 螺帽

15 CH12278 12 CH12278 結軸塊

16 CH12795 12 CH12795 PUSHROD

17 CH12808 6 CH12808 PUSHROD

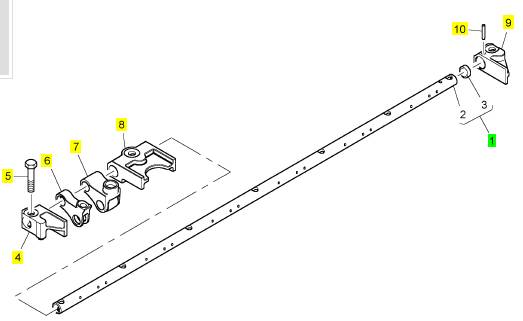

項目 零配件號碼 新件號 描述

1 CH12586 1 CH12586 軸

4 CH12590 1 CH12590 托架

5 CH11807 7 CH11807 螺拴

6 CH12587 12 CH12587 滾子

7 CH12585 6 CH12585 滾子

8 CH12589 5 CH12589 托架

9 CH12588 1 CH12588 托架

10 CH12591 1 CH12591 合釘

項目 零配件號碼 新件號 描述

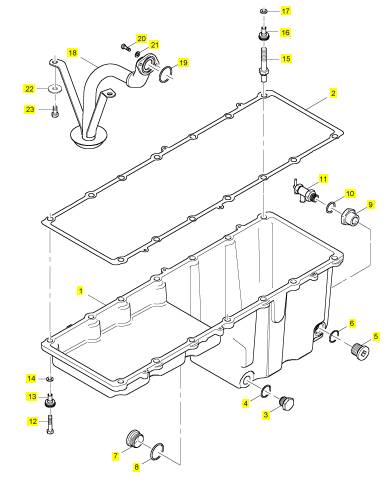

1 CH12117 1 CH12117 油底殼

2 CH12118 1 CH12118 密封墊 -油底殼

3 CH11571 1 CH11571 排泄栓塞

4 CH11573 1 CH11573 密封O型圈

5 T400251 1 T400251 栓塞

6 T400544 1 T400544 密封O型圈

7 T400251 1 T400251 栓塞

8 T400544 1 T400544 密封O型圈

9 T401275 1 T401275 承接器

10 T406205 1 T406205 密封O型圈

11 2461 A503 1 2461 A503 關閉閥

12 CH12124 13 CH12124 螺拴

13 CH12119 13 CH12119 密封墊

14 CH10113 13 CH10113 墊圈

15 CH12657 1 CH12657 圖釘

16 CH12119 1 CH12119 密封墊

17 CH10113 1 CH10113 墊圈

18 T400250 1 T400250 管 - 油的吸入

19 CH10098 1 CH10098 密封O型圈

20 CH10041 2 CH10041 螺拴

21 T401636 2 T401636 墊圈

22 CH10099 2 CH10099 墊圈

23 CH12122 2 CH12122 螺拴

項目 零配件號碼 新件號 描述

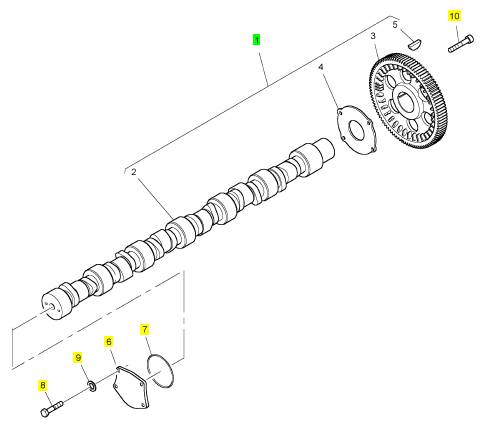

1 CH12436 1 CH12436 凸輪軸

6 CH12435 1 CH12435 蓋

7 CH12437 1 CH12437 密封O型圈

8 CH11815 4 CH11815 螺拴

9 CH10277 4 CH10277 墊圈

10 CH12438 4 CH12438 螺拴

項目 零配件號碼 新件號 描述

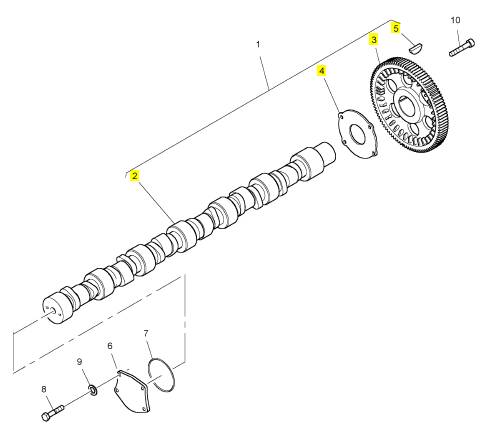

2 1 凸輪軸

3 CH12520 1 CH12520 凸輪軸傳動機構

4 CH12519 1 CH12519 推力墊圈

5 CH10005 1 CH10005 半圓鍵

項目 零配件號碼 新件號 描述

1 T401701 1 T401701 燃油濾清器

項目 零配件號碼 新件號 描述

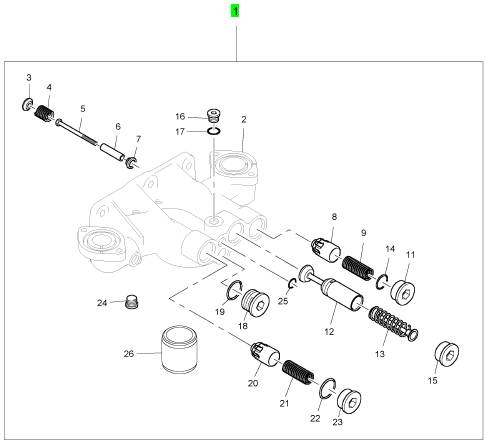

1 T401729 1 T401729 承接器

2 T400248 1 T400248 密封O型圈

3 T401731 1 T401731 管

4 T401735 2 T401735 搖臂座

5 T401734 1 T401734 水管

6 T401730 1 T401730 承接器

7 T400248 1 T400248 密封O型圈

8 T401725 1 T401725 閥

9 T401736 4 T401736 螺拴

10 CH10303 4 CH10303 墊圈

11 T401724 1 T401724 密封墊

12 T401732 1 T401732 螺拴

13 CH11819 1 CH11819 墊圈

14 T401737 1 T401737 螺拴

15 CH11819 1 CH11819 墊圈

16 T401723 1 T401723 管集箱箱

20 T401726 1 T401726 連接器

21 T400248 1 T400248 密封O型圈

22 T401733 1 T401733 水管

23 T401735 2 T401735 搖臂座

24 T401728 1 T401728 管

25 T401727 1 T401727 承接器

26 T401291 1 T401291 密封O型圈

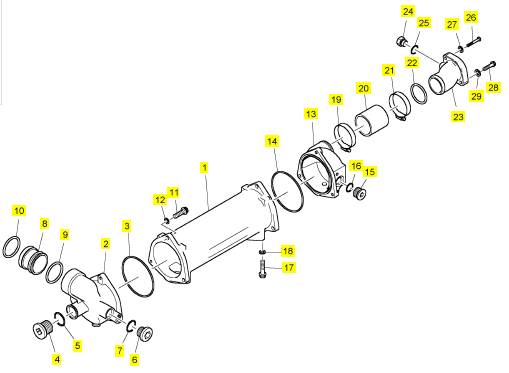

項目 零配件號碼 新件號 描述

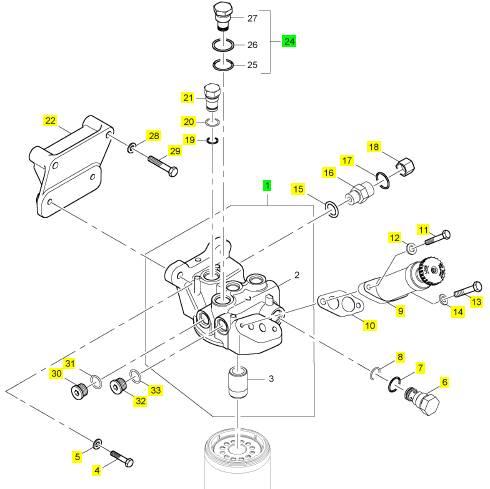

1 T400172 1 T400172 機油冷卻器

2 T400162 1 T400162 端帽

3 T400173 1 T400173 密封O型圈

4 CH10291 1 CH10291 栓塞

5 CH12240 1 CH12240 密封O型圈

6 CH12474 1 CH12474 栓塞

7 CH11621 1 CH11621 密封O型圈

8 CH10395 1 CH10395 聯結器

9 CH12238 1 CH12238 密封O型圈

10 CH12238 1 CH12238 密封O型圈

11 CH11565 6 CH11565 螺拴

12 CH10277 6 CH10277 墊圈

13 T400175 1 T400175 端帽

14 T400173 1 T400173 密封O型圈

15 CH11375 1 CH11375 栓塞

16 CH10119 1 CH10119 密封O型圈

17 CH12447 4 CH12447 螺拴

18 CH10277 4 CH10277 墊圈

19 T400174 1 T400174 搖臂座

20 CH12662 1 CH12662 水管

21 T400174 1 T400174 搖臂座

22 CH12231 1 CH12231 密封O型圈

23 T401049 1 T401049 水肘管

24 CH10285 1 CH10285 栓塞

25 CH10161 1 CH10161 密封O型圈

26 CH10140 1 CH10140 螺拴

27 CH10277 1 CH10277 墊圈

28 CH12447 1 CH12447 螺拴

29 CH10277 1 CH10277 墊圈

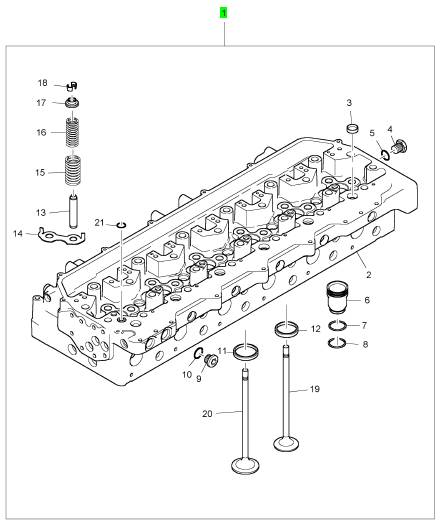

項目 零配件號碼 新件號 描述

1 CH12455 1 CH12455 汽缸蓋組合

(1) CH12455 1 CH12455 汽缸蓋裝備 -EXCH

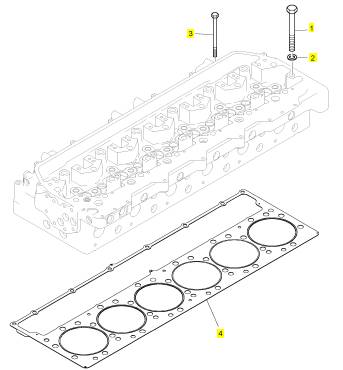

項目 零配件號碼 新件號 描述

1 CH12569 26 CH12569 汽缸蓋螺拴

2 CH12571 26 CH12571 墊圈

3 CH12570 8 CH12570 螺拴

4 CH12454 1 CH12454 密封墊 - 汽缸蓋

項目 零配件號碼 新件號 描述

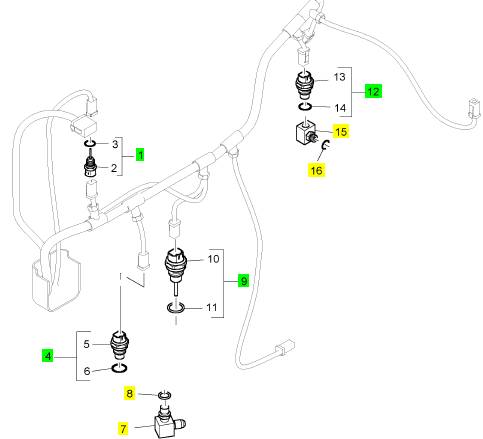

1 KRP1688 1 KRP1688 溫度感應傳感器

4 KRP1699 1 KRP1699 油壓感應傳感器裝備

7 T401655 1 T401655 肘管

8 T409314 1 T409314 密封O型圈

9 KRP1687 1 KRP1687 溫度感應傳感器

12 KRP1693 1 KRP1693 氣壓感應傳感器裝備

15 CH12642 1 CH12642 承接器

16 CH11880 1 CH11880 密封O型圈

項目 零配件號碼 新件號 描述

2 CH12652 1 CH12652 氣壓感應傳感器

3 CH11880 1 CH11880 密封O型圈

3 CH10133 1 CH10133 密封O型圈

項目 零配件號碼 新件號 描述

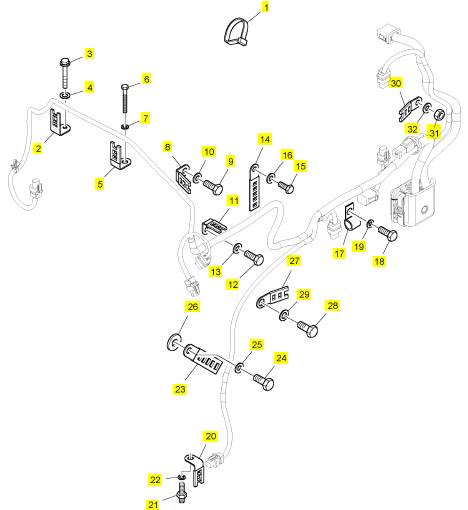

1 CH10054 13 CH10054 纜拉桿

2 T401576 2 T401576 接線夾

3 CH12286 2 CH12286 螺拴

4 CH10303 2 CH10303 墊圈

5 CH10420 1 CH10420 接線夾

6 CH11814 1 CH11814 公制的螺拴

7 CH10277 1 CH10277 墊圈

8 CH10072 1 CH10072 夾

9 CH12203 1 CH12203 螺拴

10 CH11819 1 CH11819 墊圈

11 CH10420 1 CH10420 接線夾

12 CH12203 1 CH12203 螺拴

13 CH11819 1 CH11819 墊圈

14 T401660 1 T401660 接線夾

15 CH12203 1 CH12203 螺拴

16 CH11819 1 CH11819 墊圈

17 T401662 1 T401662 接線夾

18 CH12203 1 CH12203 螺拴

19 CH11819 1 CH11819 墊圈

20 CH10420 1 CH10420 接線夾

21 CH12671 1 CH12671 圖釘

22 CH10277 1 CH10277 墊圈

23 T401660 1 T401660 接線夾

24 CH11299 1 CH11299 螺拴

25 CH11819 1 CH11819 墊圈

26 T401297 1 T401297 墊圈

27 T401661 1 T401661 接線夾

28 CH10922 1 CH10922 螺拴

29 CH10099 1 CH10099 墊圈

30 T410794 1 T410794 接線夾

31 CH11865 1 CH11865 螺帽

32 CH11819 1 CH11819 墊圈

項目 零配件號碼 新件號 描述

1 T401716 1 T401716 燃料過濾器

4 CH12612 2 CH12612 螺拴

5 CH11819 2 CH11819 墊圈

6 CH10836 1 CH10836 閥

7 T400188 1 T400188 密封O型圈

8 T400684 1 T400684 密封O型圈

9 CH10439 1 CH10439 汽酒共騰泵

10 CH10008 1 CH10008 密封墊

11 CH10246 1 CH10246 螺拴

12 CH10086 1 CH10086 墊圈

13 CH11565 1 CH11565 螺拴

14 T401636 1 T401636 墊圈

15 T408416 1 T408416 密封O型圈

16 T407241 1 T407241 連接器

17 CH11880 1 CH11880 密封O型圈

18 T409325 1 T409325 帽

19 T400857 1 T400857 密封O型圈

20 T400695 1 T400695 密封O型圈

21 T400694 1 T400694 栓塞

22 T401715 1 T401715 托架

23 T400188 1 T400188 密封O型圈

24 CH12017 1 CH12017 非回路閥

28 CH11819 2 CH11819 墊圈

29 ST43558 2 ST43558I 螺拴

30 CH10287 1 CH10287 栓塞

31 T406205 1 T406205 密封O型圈

32 CH10287 1 CH10287 栓塞

33 T406205 1 T406205 密封O型圈

項目 零配件號碼 新件號 描述

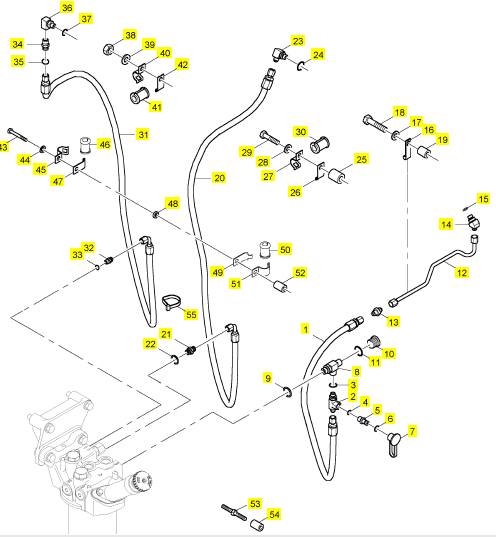

1 T401702 1 T401702 水管

2 T401708 1 T401708 承接器

3 CH11880 1 CH11880 密封O型圈

4 CH11880 1 CH11880 密封O型圈

5 CH11410 1 CH11410 栓塞

6 CH11880 1 CH11880 密封O型圈

7 CH11411 1 CH11411 灰塵盾

8 T401711 1 T401711 承接器

9 T406205 1 T406205 密封O型圈

10 CH10286 1 CH10286 栓塞

11 CH11880 1 CH11880 密封O型圈

12 T401717 1 T401717 管

13 T401704 1 T401704 承接器

14 T400646 1 T400646 承接器

15 CH11880 1 CH11880 密封O型圈

16 T401703 1 T401703 管夾

17 CH11819 1 CH11819 墊圈

18 CH11807 1 CH11807 螺拴

19 T401448 1 T401448 間隔器

20 T401714 1 T401714 水管

21 CH11595 1 CH11595 連接器

22 T406205 1 T406205 密封O型圈

23 CH10841 1 CH10841 連接

24 CH11880 1 CH11880 密封O型圈

25 T401448 1 T401448 間隔器

26 T400658 1 T400658 托架

27 T400659 1 T400659 托架

28 CH11819 1 CH11819 墊圈

29 CH11807 1 CH11807 螺拴

30 T400660 1 T400660 襯套

31 T401714 1 T401714 水管

32 CH10026 1 CH10026 連接

33 CH11880 1 CH11880 密封O型圈

34 CH10026 1 CH10026 連接

35 CH11880 1 CH11880 密封O型圈

36 T401713 1 T401713 肘管

37 CH10133 1 CH10133 密封O型圈

38 CH11865 1 CH11865 螺帽

39 CH11819 1 CH11819 墊圈

40 T400659 1 T400659 托架

41 T400660 1 T400660 襯套

42 T400658 1 T400658 托架 &, amp;, nbsp;

43 T401705 1 T401705 螺拴

44 CH10255 1 CH10255 墊圈

45 T400659 1 T400659 托架

46 T400660 1 T400660 襯套

47 T400658 1 T400658 托架

48 T401712 1 T401712 間隔器

49 T400658 1 T400658 托架

50 T400660 1 T400660 襯套

51 T400659 1 T400659 托架

52 T401707 1 T401707 間隔器

53 T401720 1 T401720 桿

54 T401706 1 T401706 間隔器

55 CH10054 2 CH10054 纜拉桿

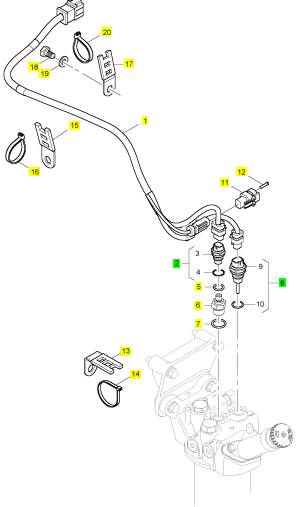

項目 零配件號碼 新件號 描述

1 T401709 1 T401709 線束

2 KRP1699 1 KRP1699 油壓感應傳感器裝備

5 T409314 1 T409314 密封O型圈

6 T400689 1 T400689 承接器

7 T406205 1 T406205 密封O型圈

8 KRP1687 1 KRP1687 溫度感應傳感器

11 28170044 1 28170044 電力有關連接器

12 2900 A011 2 2900 A011 銷

13 CH10420 1 CH10420 接線夾

14 CH10054 1 CH10054 纜拉桿

15 T410794 1 T410794 接線夾

16 CH10054 1 CH10054 纜拉桿

17 T410794 1 T410794 接線夾

18 CH12203 1 CH12203 螺拴

19 CH11819 1 CH11819 墊圈

20 CH10054 1 CH10054 纜拉桿

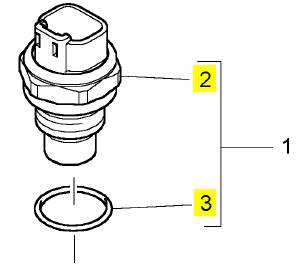

項目 零配件號碼 新件號 描述

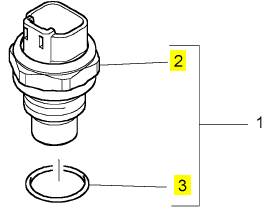

2 1 感應傳感器

3 CH10132 1 CH10132 密封O型圈

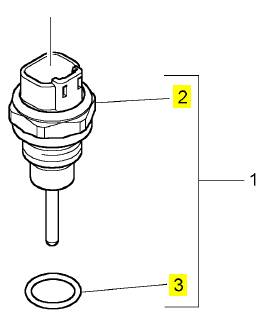

項目 零配件號碼 新件號 描述

2 1 溫度感應傳感器

3 T406205 1 T406205 密封O型圈

3 CH10230 1 CH10230 密封O型圈

項目 零配件號碼 新件號 描述

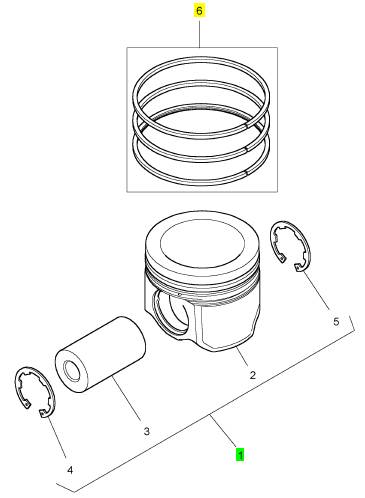

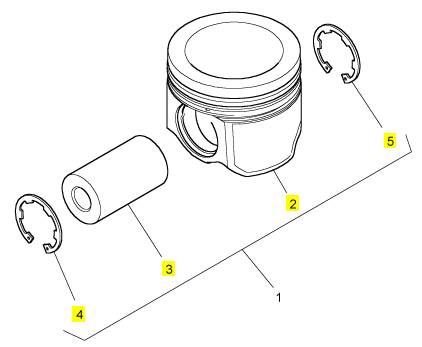

1 T401573 6 T401573 活塞裝備

6 T401572 6 T401572 活塞環裝備

項目 零配件號碼 新件號 描述

1 T401573 6 T401573 活塞裝備

6 T401572 6 T401572 活塞環裝備

項目 零配件號碼 新件號 描述

2 1 活塞

3 CH12332 1 CH12332 軸頭銷

4 CH12331 1 CH12331 CIRCLIP

5 CH12331 1 CH12331 CIRCLIP

項目 零配件號碼 新件號 描述

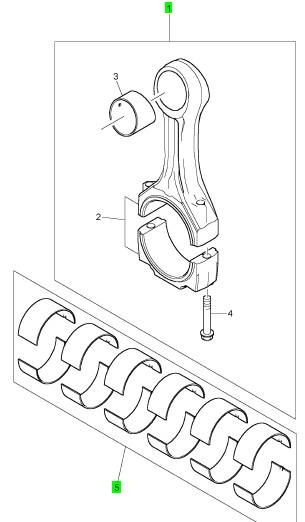

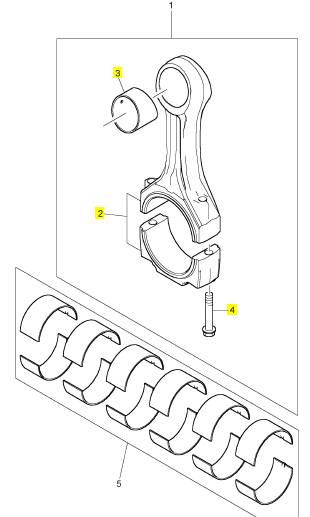

1 CH12635 6 CH12635 連桿組合

5 KRP3023 1 KRP3023 大頭軸承裝備

(5) KRP3023/051 1 KRP3023/051 大頭 BRG 裝備 -U/S

(5) KRP3023/076 1 KRP3023/076 大頭 BRG 裝備 -U/S

項目 零配件號碼 新件號 描述

2 1 連桿

3 1 連桿小的一端襯套

4 CH12499 2 CH12499 連桿螺拴

項目 零配件號碼 新件號 描述

1 T401692 1 T401692 燃油濾清器

4 CH11299 2 CH11299 螺拴

5 CH11865 2 CH11865 螺帽

6 T401694 2 T401694 螺拴

7 T401001 2 T401001 墊圈

8 T401700 1 T401700 板

9 T401696 1 T401696 承接器

10 T400544 1 T400544 密封O型圈

11 CH10822 1 CH10822 工具

12 T409314 1 T409314 密封O型圈

13 T401693 1 T401693 承接器

14 T400544 1 T400544 密封O型圈

15 2658 A101 1 2658 A101 帽

16 T401697 1 T401697 承接器

17 T400544 1 T400544 密封O型圈

18 4587260 1 4587260 濾油器

19 T401695 1 T401695 水管 -油

20 T401698 1 T401698 承接器

21 T400762 1 T400762 密封O型圈

22 T401695 1 T401695 水管 -油

23 T401699 1 T401699 承接器

24 T400762 1 T400762 密封O型圈

25 T401691 1 T401691 蓋

26 T401690 2 T401690 密封O型圈

27 T401689 1 T401689 承接器

項目 零配件號碼 新件號 描述

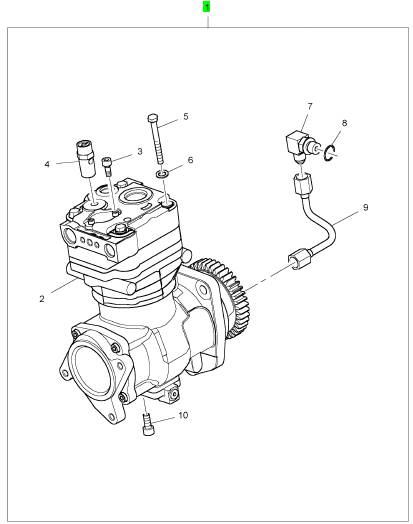

1 T400315 1 T400315 壓縮機

項目 零配件號碼 新件號 描述

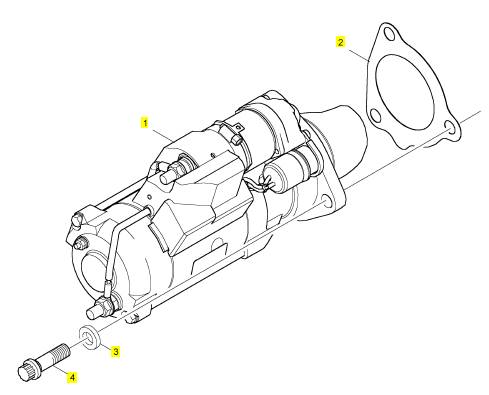

1 T400318 1 T400318 啟動馬達

2 CH10310 1 CH10310 密封墊

3 T400724 3 T400724 墊圈

4 T400720 3 T400720 螺拴

項目 零配件號碼 新件號 描述

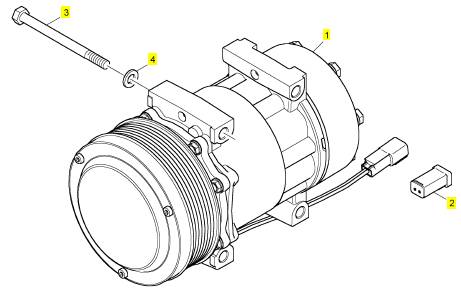

1 2488 A298 1 2488 A298 壓縮機

2 T401634 1 T401634 栓塞

3 T401635 4 T401635 螺拴

4 T401636 4 T401636 墊圈

項目 零配件號碼 新件號 描述

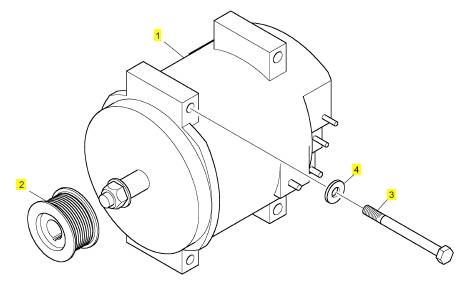

1 T400313 1 T400313 交流充電發電機

2 T401641 1 T401641 皮帶輪

3 T401642 4 T401642 螺拴

4 T407566 4 T407566 墊圈

項目 零配件號碼 新件號 描述

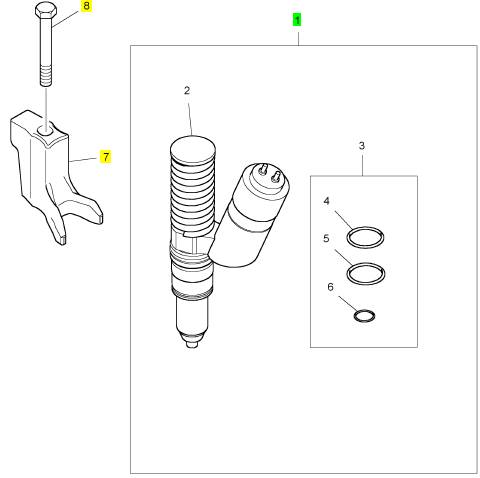

1 T401643 6 T401643 噴油器

(1) T401643R 6 T401643R 噴油器

7 CH12324 6 CH12324 噴油器搖臂座

8 CH12326 6 CH12326 螺拴

|

|

|

customer connector and the 70 pin customer

connector to 2.25 ± 0.25 N·m (20 ± 2 lb in).

Expected Result:

The ECM connector is secure and the allen head

screws are properly torqued.

Results:

• OK – The ECM connectors and the customer

connector is properly connected. Proceed to Test

Step 8.

• Not OK – The allen head screws for the ECM

connector or the customer connector is damaged.

Repair: Repair the connector or replace the

connector, as required. Verify that the repair

eliminates the fault.

STOP.

Test Step 8. Perform the “Wiggle Test”

on the Electronic Service Tool

A. Select the “Wiggle Tes t” from the diagnostic tests

on the electronic serv ice tool.

B. Choose the appropriate group of parameters to

monitor.

C. Press the “Start” button. Wiggle the wiring harness

in order to reproduce intermittent faults.

If an intermittent fault exists, the status will be

highlighted and an audible beep will be heard.

Expected Result:

No intermittent faults were indicated during the

“Wiggle Test”.

Results:

harness and connectors appear to be OK. If you

were sent from another procedure, return to the

procedure and c ontinue testing. If this test has

resolved the fault, return the engine to service.

STOP.

indicated.

Repair: Repair the harness or the connector. Verify

that the repair eliminates the fault.

STOP.

i02568609

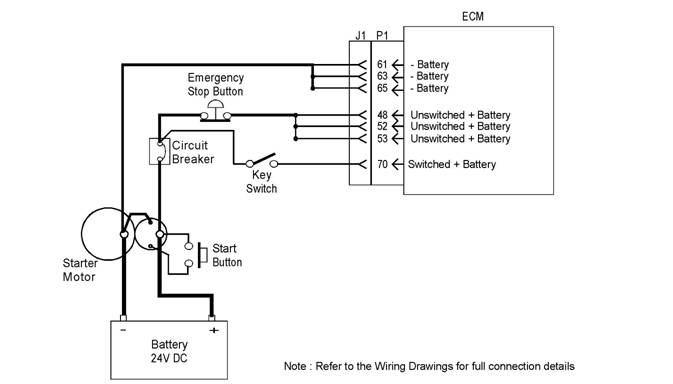

Electrical Power Supply Circuit

- Test

System Operation Description:

Use this procedure to troubleshoot any suspec ted

faults with the electrical power supply.

This procedure covers the following diagnostic codes:

• 0168-02 Electrical System Voltage erratic,

intermittent, or incorrect

This procedure tests whether proper voltage is being

supplied to the Electronic Control Module (ECM).

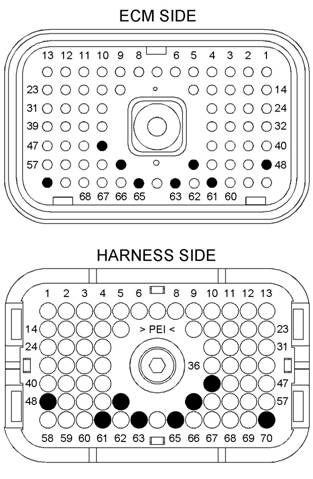

Unswitched battery voltage is supplied through the

customer connector to the ECM at P1-48, P1-52, and

P1-53. The negative battery is s upplied to the ECM

at P1-61, P1-63, and P1-65. The ECM receives the

input from the keyswitch at P1-70 when the keyswitch

is in the ON position or the START position. When

the ECM detects battery voltage at this input, the

ECM will power up. When battery voltage is removed

from this input, the ECM will power down.

The cause of an intermittent power supply to the ECM

can occur on either the positive side or the negative

side of the battery circuit. Both sides are routed from

the ECM to the battery. The three connections for

the unswitched +Battery s hould be routed through a

dedicated protective device (circuit breaker).

The engine ECM requires the keyswitch to be in the

ON position in order to maintain communications with

the electronic service tool.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]()

![]() KENR6224

KENR6224

95

Troubleshooting Section

|

Schematic diagram for the electrical power supply

Connectors and the Wiring

A. Check all circuit breakers.

B. Check the battery.

C. Turn the keyswitch to the OFF position.

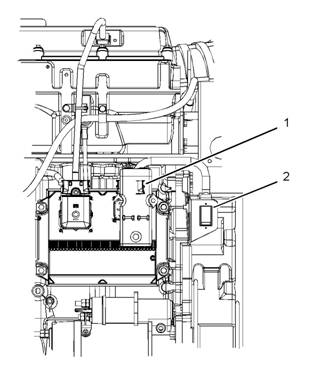

g01286846

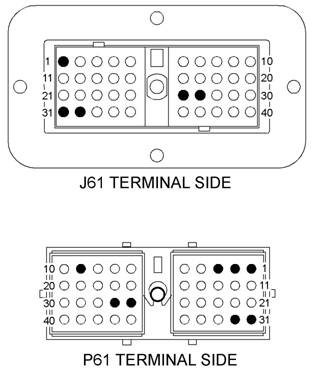

Illustration 34

Left side view

(1) J1/P1 ECM connectors

(2) P61 customer connector

g01286858

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() 96

96

Troubleshooting Section

KENR6224

D. Thoroughly inspect connectors (1) and (2).

Inspect the connections for the battery and

the connections to the keyswitch. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for details.

Illustration 36

g01216338

Illustration 35

g01104383

J61 and P61 terminals that are associated with the electrical

power supply

(1) +Battery

(26) Keyswitch

(27) Shutdown

(31) +Battery

(32) +Battery

E. Perform a 45 N (10 lb) pull test on each of the

wires that are associated with the electrical power

supply.

F. Check the allen head screw on each ECM

P1 terminals that are assoc iated with the electrical power supply

(P1-44) Shutdown

(P1-48) +Battery

(P1-52) +Battery

(P1-53) +Battery

(P1-61) −Battery

(P1-63) −Battery

(P1-65) −Battery

(P1-70) Keys witch

connector for the proper torque. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for the correct torque values.

G. Check the harnes s and wiring for abrasions and

for pinc h points from the battery to the ECM. Also,

check the harness and wiring for abrasions and

for pinch points from the key switch to the ECM.

Expected Result:

All connectors, pins, and sockets are completely

coupled and/or inserted, and the harness and wiring

are free of corrosion, of abrasion and of pinch points.

Results:

• OK – The connectors and wiring are OK. Proceed

to Test Step 2.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

97

Troubleshooting Section

•

Not OK

wiring.

– There is a fault in the connectors or

B. Load test the batteries.

Expected Result:

|

|

|

replace the connectors or wiring. Ensure that all of

the seals are properly in place and ensure that the

connectors are completely coupled.

STOP.

Test Step 2. Check the Battery Voltage at

the ECM

A. Disconnect the J1/P1 ECM connector.

B. Turn the keyswitch to the ON position.

C. Measure the voltage between P1-52 (Unswitched

Positive Battery) and P1-63 (Negative Battery).

D. Measure the voltage between P1-48 (Unswitched

Positive Battery) and P1-61 (Negative Battery).

E. Measure the voltage between P1-53 (Unswitched

Positive Battery) and P1-65 (Negative Battery).

F. Measure the voltage between P1-70 (Keyswitch)

and P1-63 (Negative Battery).

Expected Result:

The meas ured voltage is between 22.0 VDC and 27.0

VDC with no suspected intermittent faults at this time.

Results:

• OK – The ECM is receiving the correct voltage.

Repair: If an intermittent condition is suspected,

refer to the Troubleshooting Guide, “Electrical

Connectors - Inspect”.

STOP.

Step 3.

•

Repair: Check the circuit protection for the

circuit and for the wiring. Trace the wiring for the

keyswitch from the ECM through the keyswitch

circuit to the batteries. Find the fault and repair the

fault.

Verify that the repairs eliminate the fault.

STOP.

Test Step 3. Check the Batteries

A. Measure the no-load battery voltage at the battery

posts.

The batteries pass the load test. The measured

voltage is the minimum specification for a 24V

system.

Results:

• OK – The batteries are OK.

Repair: Check the wiring between the batteries

and the ECM for shorts.

Check the connectors between the batteries and

the ECM for moisture and/or corrosion.

Repair the wiring and/or the connectors.

Verify that the repair eliminates the fault.

STOP.

• Not OK – The battery voltage is low or the battery

did not pass the load test.

Repair: Recharge or replace the faulty batteries.

Verify that the repair eliminates the fault.

STOP.

i02568670

Engine Pressure Sensor Open

or Short Circuit - Test

System Operation Description:

Use this procedure to troubleshoot any suspect faults

with the following sensors:

• Engine oil pressure sensor

• Inlet manifold pressure sensor

• Atmospheric pres sure sensor

This procedure covers the following diagnostic codes:

• 0100-03 Engine Oil Pressure Sensor voltage

above normal

• 0100-04 Engine Oil Pressure Sensor voltage below

normal

• 0273-03 Turbocharger Outlet Pressure Sensor

voltage above normal

This document has been printed from SPI². Not for Resale

![]() 98

98

Troubleshooting Section

KENR6224

•

•

•

0273-04 Turbocharger Outlet Pres sure Sensor

voltage below normal

0274-03 Atmospheric Pressure Sensor voltage

above normal

0274-04 Atmospheric Pressure Sensor voltage

below normal

The troubleshooting procedures for the diagnostic

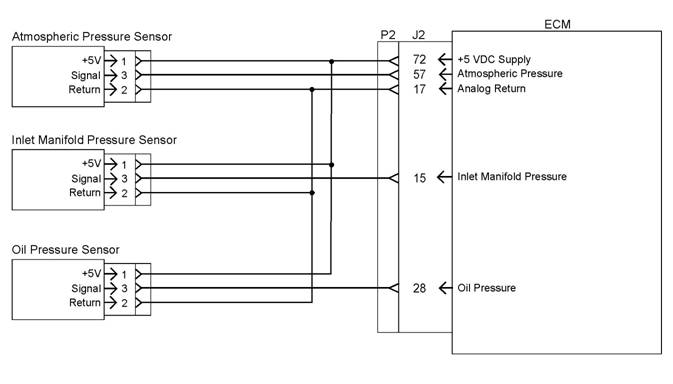

codes of each pressure sensor are identical. The

Engine Control Module (ECM) sends a 5 volt supply

to terminal 1 of each sensor. The sensor common

connection is connected to terminal 2 of each sensor.

The signal voltage from terminal 3 of each sensor is

sent to the appropriate terminal at the J2/P2 ECM

connector.

Pull-up Voltage

The ECM continuously outputs a pull-up voltage

on the circuit for the sensor signal wire. The ECM

uses this pull-up voltage in order to detect an open

in the signal circuit. When the ECM detects the

presence of a voltage that is above a threshold on the

signal circuit, the ECM will generate an open circuit

diagnostic code (03) for the sens or.

If the sensor is disconnected at the s ensor connector,

the presence of pull-up voltage at the sensor

connector indicates that the wires from the sensor

connector to the ECM are not open or shorted to

ground. If the sensor is disconnected at the sensor

connector, the absence of pull-up voltage at the

sensor connector indicates an open in the signal wire

or a short to ground. If the sensor is disconnected at

the sensor connec tor and the voltage at the sensor

connector is different from pull-up voltage, the signal

wire is shorted to another wire in the harness.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() KENR6224

KENR6224

99

Troubleshooting Section

Illustration 37

Schematic for the engine pressure sensors

g01284368

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() 100

100

Troubleshooting Section

KENR6224

|

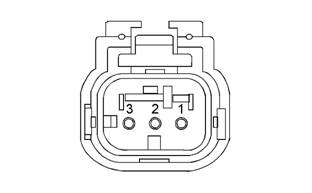

Sensor connector

(1) +5 VDC

(2) Common

(3) Signal

Connectors and Wiring

Electrical

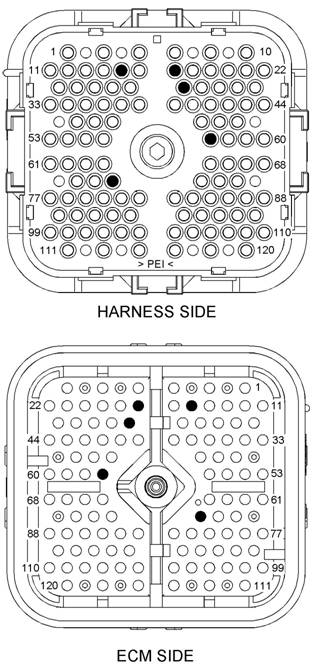

g01287356

Illustration 38

P2 ECM connector

(P2-15) Signal from the inlet manifold pressure sensor

(P2-17) Sensor common

(P2-28) Signal from the oil pressure sensor

(P2-57) Atmospheric pressure sensor signal

(P2-72) +5 Volt sensor supply

g01287043

A. Turn the keyswitch to the OFF position.

B. Thoroughly inspect the J1/P1 ECM connector and

the J2/P2 ECM connector. Thoroughly inspect the

connectors for each analog sensor. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for details.

C. Perform a 45 N (10 lb) pull test on each of the

wires that are associated with the active diagnostic

code.

D. Check the allen head screw on each ECM

connector for the proper torque. Refer to the

Troubleshooting Guide, “Electrical Connectors -

Inspect” for the correct torque values.

E. Check the harness and wiring for abrasions and

for pinch points from each sensor back to the

ECM.

Expected Result:

All connectors, pins, and sockets are completely

coupled and/or inserted. The harness and wiring are

free of corrosion, of abrasion, and of pinch points .

Results:

• OK – The harnes s and wiring are OK. Proceed

to Test Step 2.

• Not OK – There is a fault in the connectors and/or

wiring.

This document has been printed from SPI². Not for Resale