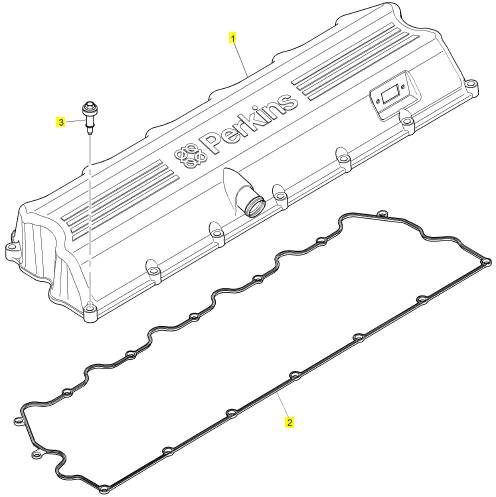

Perkins2306柴油發動機威爾遜P550柴油發電機配件

詳細描述

項目 零配件號碼 新件號 描述

1 CH11453 1 CH11512 CYL 蓋 ASSY

2 CH11353 1 CH11353 密封墊 - 搖臂室蓋

3 CH10955 14 CH10955

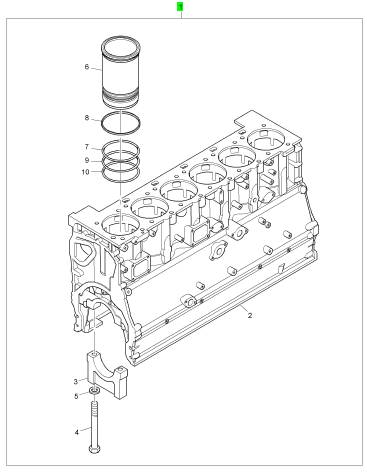

項目 零配件號碼 新件號 描述

1 CH11178 1 檢查歷史 缸體組合

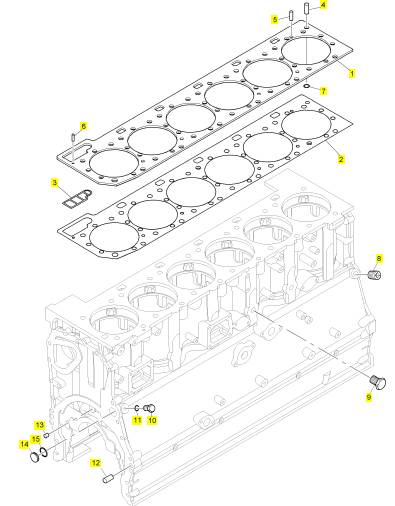

項目 零配件號碼 新件號 描述

1 CH10662 1 CH10662 間隔器

2 1 密封墊

3 1 密封墊

4 CH10661 1 CH10661 合釘

5 CH10656 1 CH10656 合釘

6 CH10659 1 CH10659 合釘

7 CH10660 1 CH10660 密封O型圈

8 CH10221 5 CH10221 栓塞

9 CH10568 2 CH11963 栓塞

10 CH10664 1 CH10664 栓塞

11 CH10667 1 CH10667 密封O型圈

12 CH10658 2 CH10658 合釘

13 CH10663 1 CH10663 栓塞

14 CH10666 2 CH10666 栓塞

15 CH10657 2 CH10657 密封O型圈

Troubleshoot ing

Event Code

with

an

Event Codes

i02564763

Event codes alert the operator that an abnormal

engine operating condition such as low oil pressure or

high coolant temperature has been detected. When

the event code is generated, the event is active.

Active Event Codes

An active event code represents a fault with engine

operation. Correct the fault as soon as possible.

Active event codes are listed in ascending numerical

order. The code with the lowest number is listed first.

Illustration 11 is an example of the operating range of

a temperature sensor. Do not use the illustration to

troubleshoot temperature sensors.

Illustration 11

g01138880

Example of the typical operating range of a temperature sensor

(1) This area represents the normal operating range of the

parameter. The normal output voltage of the sensor is between

0.2 VDC and 4.2 VDC.

(2) In this area, the temperature above 107 °C (225 °F) is higher

than normal. The output voltage of the sensor will generate an

event code. The sensor does not have an electronic fault.

(3) In these areas, the output voltage of the sensor is too high

or too low. The voltage is outside of the normal range. The

elec tronic fault will generate a diagnostic code. Refer to

Troubleshooting, “Troubleshooting with a Diagnostic Code” for

additional information on diagnostic codes.

Events are represented in two formats. In the first

format, the “E” means that the code is an event

code. The “XXX” represents a numeric identifier for

the event code. This is followed by a description of

the code. If a warning, a derate, or a shutdown is

applicable, the numeric identifiers are different. Refer

to the following example:

• E004 Engine Overs peed Shutdown

In the second format, the “E” means that the

code is an event code. The “XXX-X” represents a

numeric identifier for the event code. The fourth “X”

identifies the event as a warning, an ac tion alert, or

a shutdown. This is followed by a description of the

code. Refer to the following example:

This document has been printed from SPI². Not for Resale

![]() 68

68

Troubleshooting Section

KENR6224

•

•

•

E360-1 Low Oil Pressure Warning

E360-2 Low Oil Pressure Action Alert

E360-3 Low Oil Pressure Shutdown

Troubleshooting

For basic troubleshooting of the engine, perform the

following steps in order to diagnose a fault:

1. Obtain the following information about the fault:

The definition for a warning, an action alert and a

shutdown are defined below:

Warning – This condition represents a serious fault

with engine operation. However, this c ondition does

not require an action alert or a s hutdown.

Action Alert – For this condition, the OEM control

panel may shut down the engine.

Shutdown – For this condition, the ECM should shut

down the engine.

Logged Event Codes

•

•

•

•

The event and the time of the event

Determine the conditions for the event. The

conditions will include the engine rpm and the

load.

Determine if there are any systems that were

installed by the dealer or by the customer that

could cause the event.

Determine whether any additional events

occurred.

When the ECM generates an event code, the ECM

logs the code in permanent memory. The ECM has

an internal diagnostic clock. The ECM will record

the following information when an event code is

generated:

• The hour of the first occurrence of the code

• The hour of the last occurrence of the code

• The number of occurrences of the code

Logged events are listed in chronological order. The

most recent event code is listed first.

This information can be helpful for troubleshooting

intermittent faults. Logged codes can als o be used to

review the performance of the engine.

Clearing Event Codes

2.

3.

4.

Verify that the fault is not due to normal engine

operation. Verify that the fault is not due to error of

the operator.

Narrow the probable cause. Consider the operator

information, the conditions of operation, and the

his tory of the engine.

Perform a visual inspection. Inspect the following

items:

• Fuel supply

• Oil level

• Oil supply

• Wiring

• Connectors

A code is cleared from memory when one of the

following conditions occur:

• The code does not recur for 100 hours.

• A new code is logged and there are already ten

codes in memory. In this case, the oldest code is

cleared.

• The service technician manually clears the code.

Always clear logged event codes after investigating

and correcting the fault which generated the code.

Be sure to check the connectors. This is very

important for faults that are intermittent. Refer to

Troubleshooting, “Electrical Connectors - Inspect”.

If these steps do not resolve the fault, identify the

procedures in this manual that best describe the

event. Check each probable cause according to the

tests that are recommended.

Trip Points for the Monitoring

System

The monitoring system determines the level of action

that is taken by the ECM in response to a condition

that can damage the engine. When any of these

conditions occur, the appropriate event code will trip.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

69

Troubleshooting Section

Table 11 contains the conditions that are monitored

and the default trip points for each condition.

Each condition has an associated parameter. The

settings for each parameter can be viewed with the

electronic service tool. The trip points for some of

the parameters may be adjustable with the electronic

service tool.

Table 11

Event Code

E162

-1

Parameter

High Boost Pressure

Warn Operator (1)

On

State

Trip Point

300 kPa (43.5 psi)

Delay Time

30 seconds

-2

E360

-1

-2

-3

E361

-1

-2

-3

E362

-1

-2

-3

E363

-1

-2

Acti on Alert (2)

Low Engine Oil Pressure

Warn Operator (1)

Acti on Alert (2)

Engine Shutdown (3)

High Engine Coolant Temperature

Warn Operator (1)

Acti on Alert (2)

Engine Shutdown (3)

Engine Overspeed

Warn Operator (1)

Acti on Alert (2)

Engine Shutdown (3)

High Fuel Supply Temperature

Warn Operator (1)

Acti on Alert (2)

Always On

On

Always On

Always On

On

Always On

Always On

On

Always On

Always On

On

Always On

None

300 kPa (43.5 psi)

None

None

104 °C (2190 °F)

105 °C (221 °F)

108 °C (226 °F)

2000 RPM

2050 RPM

2140 RPM

60 °C (140 °F)

68 °C (154 °F)

5 seconds

60 seconds

2 seconds

2 seconds

60 seconds

10 seconds

10 seconds

1 second

1 second

0 second

60 seconds

60 seconds

E368

-1

-2

High Engine Intake Manifold Air Temperature

Warn Operator (1) On

Acti on Alert (2) Always On

75 °C (167 °F)

78 °C (172 °F)

60 seconds

10 seconds

E162 High

Boost Pressure

i02564844

Possible Performance Effect:

E162-1 (Warning)

None

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects one of

the following conditions:

• Engine overload

System Response:

The event code will be logged.

E162-2 (Action Alert)

The engine may be shut down by the OEM control

panel.

Troubleshooting:

The engine may be overloaded.

Reduce the load on the engine.

This document has been printed from SPI². Not for Resale

![]() 70

70

Troubleshooting Section

KENR6224

Results:

• OK – STOP.

E360 Low Engine

i02564766

Oil Pressure

b. Oil pump gears that have too much wear will

cause a reduction in oil pressure. Repair the

engine oil pump.

C. The inlet screen of the oil suction tube for the

engine oil pump can have a restriction. This

restriction will cause cavitation and a loss of

engine oil pres sure. Check the inlet screen on

the oil pickup tube and remove any material that

may be restricting engine oil flow. Low engine oil

pressure may also be the result of the oil pickup

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects a fault

with the engine oil pressure. Information on default

settings and ranges for this event can be found in

Troubleshooting, “Event Codes”.

System Response:

The event code will be logged.

Possible Performance Effect:

E360-1 (Warning)

None

E360-2 (Action Alert)

The engine may be shut down by the OEM control

panel.

E360-3 (Shutdown)

The engine will shut down.

Troubleshooting:

There may be a fault in the lubrication system for

the engine.

Check the Engine’s Lubrication System

A. Check the engine oil level. If the oil lev el is below

the s upply tube for the oil pump, the oil pump will

not have the ability to supply enough lubrication to

the engine components. If the engine oil level is

low, add engine oil in order to obtain the correct

engine oil level.

B. Check the following faults that may occur to the

engine oil pump:

a. Air leakage in the supply side of the oil pump

will also cause cavitation and loss of oil

pressure. Check the supply side of the oil pump

and make necessary repairs.

tube that is drawing in air. Check the joints of the

oil pickup tube for cracks or a damaged O-ring

seal.

D. If the engine oil bypass valves are held in the

open position, a reduction in the oil pressure can

be the result. This may be due to debris in the

engine oil. If the engine oil bypass valves are

stuck in the open position, remove each engine

oil bypass valve and clean each bypass valve in

order to correct this fault. You must also clean

each bypass valve bore.

E. Engine oil that is c ontaminated with fuel or coolant

will cause low engine oil pressure. High engine

oil level in the crankcase can be an indication of

contamination.

F. Excessive clearance at engine bearings will

cause low engine oil pres sure. Check the engine

components for excessive bearing clearance.

G. An oil line that is open, broken, or disconnected

will cause low engine oil pressure.

Expected Result:

An inspection of the lubrication system for the engine

indicated a fault.

Results:

• OK – There is a fault in the lubrication system for

the engine.

Repair: Repair the fault. Ensure that the repair

eliminates the fault.

STOP.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

71

Troubleshooting Section

E361

High

Engine

i02564767

Coolant

D. Check the water temperature regulator. A water

temperature regulator that does not open, or a

water temperature regulator that only opens part

of the way can cause overheating.

Temperature

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects a fault

in the engine cooling sy stem. Information on default

settings and ranges for this event can be found in

Troubleshooting, “Event Codes”.

System Response:

The event code will be logged.

Possible Performance Effect:

E361-1 (Warning)

• There are no performance effects.

E361-2 (Action Alert)

• The engine may be shut down by the OEM control

panel.

E361-3 (Shutdown)

• The engine will be shut down.

Troubleshooting:

There may be a fault in the engine cooling system.

Check the Engine’s Cooling System

A. Verify that the cooling sy stem is filled to the proper

lev el. If the coolant level is too low, air will get into

the cooling system. Air in the cooling system will

cause a reduction in coolant flow.

B. Check the radiator or the heat exchanger for a

restriction to coolant flow.

a. Check for debris or damage between the fins

of the radiator core. Debris between the fins of

the radiator core restricts air flow through the

radiator core.

b. Check internally for debris, dirt, or deposits on

the radiator core. Debris, dirt, or deposits will

restrict the flow of coolant through the radiator.

C. Check the concentration of the Extended Life

Coolant (ELC). Make sure that the coolant

mixture meets recommendations. Refer to the

Operation and Maintenance Manual, “Fluid

Recommendations”.

E. Check the water pump. A water pump with a

damaged impeller does not pump enough coolant.

Remove the water pump and check for damage

to the impeller.

F. If the cooling system for this application is

equipped with a fan, check the operation of the

fan. A fan that is not turning at the correct speed

can cause improper air speed across the radiator

core. The lack of proper air flow across the

radiator c ore can cause the coolant not to cool to

the proper temperature differential.

G. Check for air in the cooling system. Air can enter

the cooling s ystem in different ways. The most

common causes of air in the cooling system are

the incorrect filling of the cooling system and

combustion gas leakage into the cooling system.

Combustion gas can get into the system through

inside cracks, a damaged cylinder head, or a

damaged cylinder head gasket.

H. Check the cooling system hoses and clamps.

Damaged hoses with leaks can normally be seen.

Hoses that have no visual leaks can soften during

operation. The soft areas of the hose can become

kink ed or crushed during operation. These areas

of the hose can restrict the coolant flow. Hoses

become soft and/or get cracks after a period of

time. The inside of a hose can deteriorate, and the

loose particles of the hos e can restrict the coolant

flow.

I. If the cooling system for this application is

equipped with an expansion tank, check the s hunt

line for the expansion tank. The shunt line must be

submerged in the expansion tank. A res triction of

the shunt line from the expansion tank to the inlet

of the jacket water pump will c ause a reduction in

water pump efficiency. A reduction in water pump

efficiency will result in low coolant flow.

J. If the cooling system for this application

is equipped with an aftercooler, check the

aftercooler. A restriction of air flow through the air

to air aftercooler c an cause overheating. Check

for debris or deposits which would prevent the free

flow of air through the aftercooler.

K. Check for a restriction in the air inlet system. A

restriction of the air that is coming into the engine

can cause high cylinder temperatures. High

cylinder temperatures cause higher than normal

temperatures in the cooling system.

L. Check for a restriction in the exhaust system.

A restriction of the air that is coming out of the

engine can c ause high cylinder temperatures.

This document has been printed from SPI². Not for Resale

![]() 72

72

Troubleshooting Section

KENR6224

M. Consider high ambient temperatures. When

ambient temperatures are too high for the rating

of the cooling system, there is not enough of a

temperature difference between the ambient air

and c oolant temperatures.

N. Consider high altitude operation. The cooling

capability of the cooling system is reduced at

higher altitudes. A pressurized cooling system that

is large enough to keep the coolant from boiling

must be used.

O. The engine may be running in the lug condition.

When the load that is applied to the engine is

too large, the engine will run in the lug condition.

When the engine is running in the lug condition,

engine rpm does not increase with an increase of

fuel. This lower engine rpm causes a reduction in

coolant flow through the s ystem.

Expected Result:

A thorough inspection of the cooling system revealed

a fault.

Results:

• OK – There is a fault in the cooling sy stem.

Repair: Repair the fault. Ensure that the repair

eliminates the fault.

STOP.

i02564769

E362 Engine Overspeed

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects an

overspeed condition. Information on default settings

and ranges for this event can be found in the

Troubleshooting Guide, “Event Codes”.

System Response:

The event code will be logged.

Possible Performance Effect:

E362-1 (Warning)

None

E362-2 (Action Alert)

The engine may be shut down by the OEM control

panel.

E362-3 (Shutdown)

The engine will be shut down.

Troubleshooting:

The operator may be operating the machine

incorrectly.

The governor gain may be set incorrectly.

Talk to the Operator

Determine the events that caused the overspeed of

the engine.

If necessary, adjust the gains on the governor.

Results:

• OK – STOP.

i02564853

E363 High Fuel Supply

Temperature

Conditions Which Generate This Code:

The temperature of the fuel has exceeded the trip

point. Information on default settings and ranges for

this event code can be found in the Troubleshooting

Guide, “Event Codes”.

System Response:

The event code is logged.

Possible Performance Effect:

E363-1 (Warning)

None

E363-2 (Action Alert)

The OEM control panel may shut down the engine.

Troubleshooting:

Check the Fuel System

Check the fuel system. If equipped, check the fuel

cooler.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

73

Troubleshooting Section

Expected Result:

A thorough inspection of the fuel s ystem revealed a

fault.

Results:

a.

Verify that the cooling system is filled to the

proper level. If the coolant level is too low,

air will get into the cooling system. Air in the

cooling system may cause cavitation. This will

cause a reduction in coolant flow which can

damage a cooling s ys tem.

•

OK

– There is a fault in the fuel system.

b. Check the quality of the coolant. Follow

the recommendations in the Operation and

Repair: Make the necessary repairs. Verify that

the repair eliminates the fault.

STOP.

i02565203

E368 High Intake Manifold Air

Temperature

c.

Maintenance Manual.

Check for adequate coolant flow through

the radiator. Check the inlet temperature of

the coolant at the radiator inlet. Compare

the reading to the regulated temperature.

If the temperature is OK, c heck the outlet

temperature of the coolant at the radiator

outlet. A high temperature differential indicates

an insufficient flow rate.

Conditions Which Generate This Code:

The Electronic Control Module (ECM) detects a fault

in the inlet manifold air temperature. Information on

default settings and ranges for this event can be

found in the Troubleshooting Guide, “Event Codes ”.

System Response:

The event code will be logged.

Possible Performance Effect:

E368-1 (Warning)

None

E368-2 (Action Alert)

The OEM control panel may shut down the engine.

Troubleshooting:

Inlet manifold air temperature can be high for the

following reasons:

• Engine cooling system

• High ambient air temperature

• High inlet air restriction and/or high altitude

• Restriction in the exhaust system

• Faulty inlet manifold temperature sensor and/or

circuit

Perform the following Inspect ions

A. Check for Cooling System Faults

d. Check for air in the cooling system. Air can

enter the cooling system in different ways . The

most common causes of air in the cooling

system are the incorrect filling of the cooling

system and combustion gas leakage into

the cooling system. Combustion gas can get

into the system through a cracked cylinder

liner, damaged cylinder liner seals, a crac ked

cylinder head, or a damaged c ylinder head

gasket.

e. Check the cooling system hoses and clamps.

Damaged hoses with leak s can normally be

seen. Hoses that have no visual leaks can

soften during operation. The soft areas of the

hose can become kinked during operation.

These areas can also collapse during

operation. These areas of the hose can restrict

the coolant flow. Hoses become soft and/or get

cracks after a period of time. The inside of a

hose can deteriorate, and the loose particles of

the hose can restrict the coolant flow.

f. Check the water pump. A water pump with

a damaged impeller does not pump enough

coolant. Remove the water pump and check for

damage to the impeller.

g. Check the water temperature regulator. A water

temperature regulator that does not open, or a

water temperature regulator that only opens

part of the way can cause overheating.

h. If the cooling system is equipped with an

aftercooler, chec k the aftercooler. A restriction

of air flow through the air to air aftercooler can

cause overheating of the engine. Check for

debris or deposits which would prevent the free

flow of air through the aftercooler.

This document has been printed from SPI². Not for Resale

![]() 74

74

Troubleshooting Section

KENR6224

i.

The engine may be running exc essively in the

lug condition. When the load that is applied to

the engine is too large, the engine will run in

the lug condition. When the engine is running in

the lug condition, engine rpm does not increase

with an increase of fuel. This lower engine rpm

causes a reduction in coolant flow through the

system. The lug condition causes excess heat

from the increase in fuel consumption.

Expected Result:

A fault has been found in the cooling system and/or

the related engine systems.

Results:

• OK – A thorough inspection revealed a fault.

Repair: Repair the fault. Ensure that the repair

B. Check for High Ambient Air Temperature

a. Determine if the ambient air temperature

is within the design specifications for the

cooling system. When ambient temperatures

are too high for the rating of the cooling

system, there is not enough of a temperature

difference between the ambient air and coolant

temperatures.

b. Determine the cause of the high air

temperature. Correct the situation, when

possible.

C. Check for High Inlet Air Restriction and/or

High Altitude Operation

a. When inlet air pressure is low, the turbocharger

works harder in order to achieve the desired

inlet manifold pressure. This increases inlet air

temperature.

b. Measure the inlet air pressure while the engine

is operating under load. For specific data, refer

to the Technical Data Sheets for the engine.

c. Check for plugged air filters. Check for

obstructions to the air inlet. A restriction of

the air that enters the engine can c ause

high cylinder temperatures. High cylinder

temperatures cause higher than normal

temperatures in the cooling system.

d. Replace the air filters and/or remove the

obstruction from the air inlet.

e. Consider high altitude operation. The cooling

capability of the cooling system is reduced at

higher altitudes. A pres surized cooling system

that has been designed for the higher altitudes

must be used. Ensure that the engine is

configured for high altitude operation.

D. Check for Exhaust System Restriction

Check for a restriction in the exhaust system.

A restriction of the air that is coming out of the

engine can cause high cylinder temperatures.

eliminates the fault.

STOP.

This document has been printed from SPI². Not for Resale

![]() KENR6224

KENR6224

75

Troubleshooting Section

Diagnosti c

Tests

Functional

5

i02565206

Volt Engine Pressure Sensor

Supply

Circuit - Test

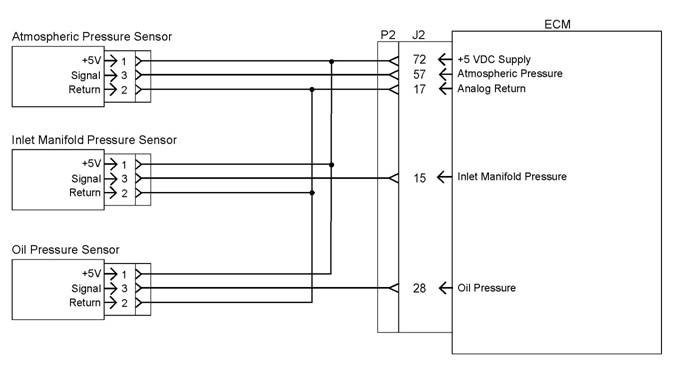

System Operation Description:

The Electronic Control Module (ECM) creates a

regulated voltage of 5.0 ± 0.2 VDC that is supplied

to terminal 1 of the harness connectors for these

sensors:

• Inlet manifold pressure sensor

• Atmospheric pressure sensor

• Engine oil pressure sensor

This procedure covers the following diagnostic codes :

• 262-03 5 Volt Sensor DC Power Supply voltage

above normal

• 262-04 5 Volt Sensor DC Power Supply voltage

below normal

A +5 V diagnostic code is probably caused by a short

circuit to ground or a short circuit to another voltage

source in the harness. The next likely cause is a faulty

sensor. The least likely cause is a fault in the ECM.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]() 76

76

Troubleshooting Section

KENR6224

Illustration 12

Schematic for the 5 volt supply

Test Step 1. Inspect the

Electrical

g01284368

Connectors and the Wiring

A. Turn the keyswitch to the OFF position.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6224

KENR6224

77

Troubleshooting Section

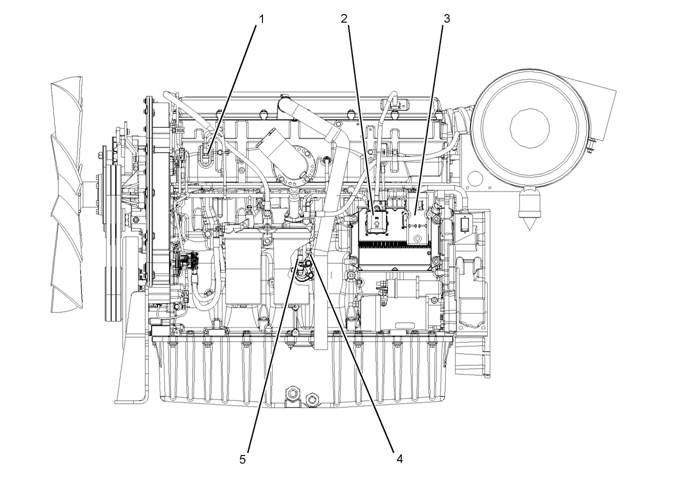

Illustration 13

Left side view

(1) Inlet manifold pressure sensor

(2) J2/P2 connector

(3) J1/P1 connector

(4) Engine oil pres sure sensor

(5) Atmospheric pressure sensor

g01284496

B. Thoroughly inspect connectors (3) and (4).

Thoroughly inspect the connectors for each

pressure sensor. Refer to Troubleshooting,

“Elec trical Connectors - Inspec t”.

This document has been printed from SPI². Not for Resale