Perkins2306柴油發動機威爾遜P550柴油發電機配件傳感器

詳細描述

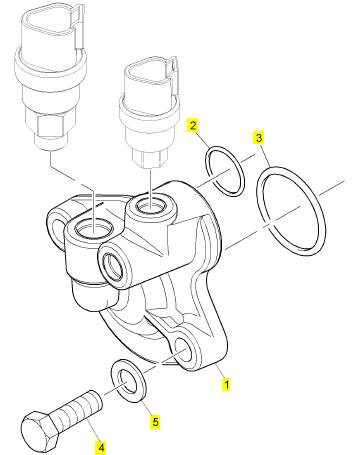

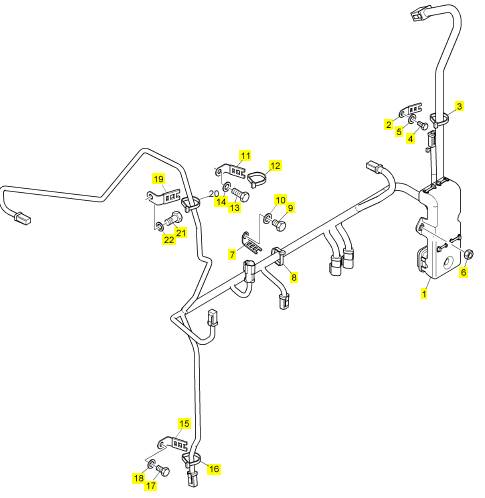

項目 零配件號碼 新件號 描述

1 CH10907 1 CH10907 承接器

2 CH10875 1 CH10875 密封O型圈

3 CH10228 1 CH10228 密封O型圈

4 CH10567 2 CH10567 螺拴

5 CH10541 2 CH10255 墊圈

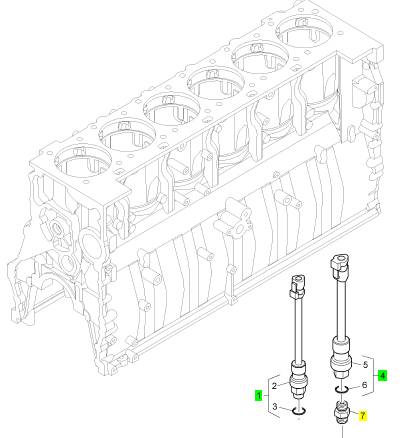

項目 零配件號碼 新件號 描述

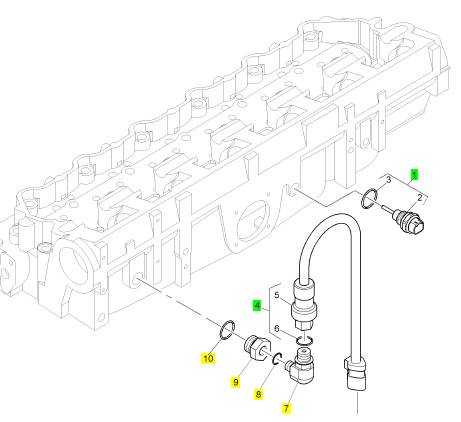

1 KRP1560 1 KRP1560 氣壓感應傳感器裝備

4 KRP1559 1 KRP1559 油壓感應傳感器裝備

7 CH10873 1 CH10873 連接器

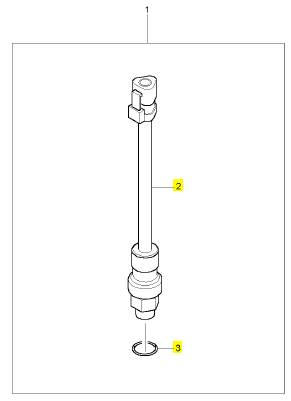

項目 零配件號碼 新件號 描述

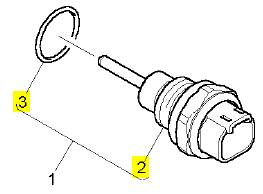

2 1 感應傳感器

3 CH10380 1 CH10380 密封O型圈

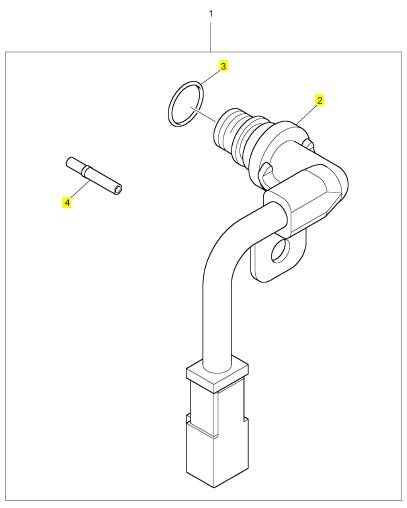

項目 零配件號碼 新件號 描述

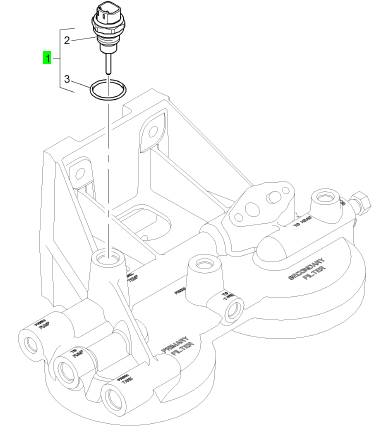

2 1 速度感應傳感器

3 CH10380 1 CH10380 密封O型圈

4 CH11170 2 2900 A016 套筒

項目 零配件號碼 新件號 描述

1 KRP1556 1 KRP1556 氣溫感應傳感器裝備

4 KRP1558 1 KRP1558 氣壓感應傳感器裝備

7 CH10706 1 CH10706 肘管

8 CH10132 1 CH10132 密封O型圈

9 CH10702 1 CH10702 承接器

10 CH10704 1 CH10704 密封O型圈

項目 零配件號碼 新件號 描述

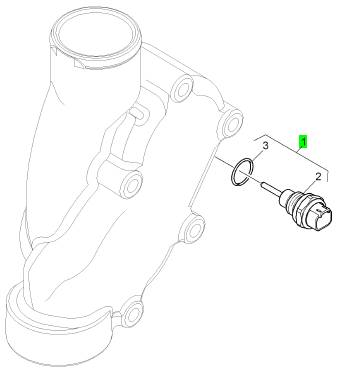

2 1 溫度感應傳感器

3 CH10871 1 CH10871 密封O型圈 圈

項目 零配件號碼 新件號 描述

1 KRP1557 1 KRP1557 感應傳感器

項目 零配件號碼 新件號 描述

1 KRP1557 1 KRP1557 感應傳感器

項目 零配件號碼 新件號 描述

1 CH10972 1 CH10972 線束

2 CH10071 2 T410794 夾

3 CH10054 2 CH10054 纜拉桿

4 CH10794 2 CH11897 螺拴

5 CH10541 2 CH10255 墊圈

6 CH10290 2 CH10798 螺帽

7 CH10799 2 CH10799 夾

8 CH10054 2 CH10054 纜拉桿

9 CH10797 2 CH10797 螺拴

10 CH10100 2 CH10100 墊圈

11 CH10072 1 CH10072 夾

12 CH10054 1 CH10054 纜拉桿

13 CH10537 1 CH11895 螺拴

14 CH10541 1 CH10255 墊圈

15 CH10072 2 CH10072 夾

16 CH10054 2 CH10054 纜拉桿

17 CH10794 2 CH11897 螺拴

18 CH10541 2 CH10255 墊圈

19 CH10072 1 CH10072 夾

20 CH10054 1 CH10054 纜拉桿

21 CH10796 1 CH10796 螺拴

22 CH10277 1 CH10277 墊圈

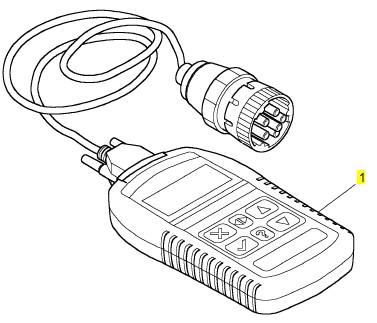

項目 零配件號碼 新件號 描述

1 27610337 1 27610337 電子的診斷工具

7.

8.

9.

Turn the flywheel counterclockwise in order to

put the dial indicator at position (D). Write the

measurement in the chart.

Add the lines together in each column.

Subtract the smaller number from the larger

number in column B and column D. Place this

number on line III. The result is the horizontal

eccentricity (out of round). Line III in column C is

the vertical eccentricity.

Vibration Damper - Check

i02553546

Illustration 50

(1) Adapter

(2) Vibration damper

(3) Bolts

(4) Crankshaft pulley

g01287000

Illustration 49

Graph for total eccentricity

(1) Total vertical ecc entricity

(2) Total horizontal eccentricity

(3) Acceptable value

(4) Unacceptable value

g00286046

|

|

vibration damper will increase vibrations. This will

result in damage to the crankshaft.

Replace the damper if any of the following conditions

exist:

from the damper.

excessive heat.

• The damper is bent.

10. Find the intersection of the eccentricity lines

(vertical and horizontal) in Illustration 49.

11. If the point of the intersection is in the “Acceptable”

range, the bore is in alignment. If the point of

intersection is in the “Not acceptable” range, the

flywheel hous ing must be c hanged.

•

•

The bolt holes are worn or there is a loose fit for

the bolts.

The engine has had a crankshaft failure due to

torsional forces.

NOTICE

Inspect the viscous vibration damper for signs of leak-

ing and for signs of damage to the case. Either of

these conditions can cause the weight to contact the

case. This contact can affec t damper operation.

This document has been printed from SPI². Not for Resale

![]()

![]()

![]()

![]() 54

54

Testing and Adjusting Section

KENR6231

Ele ct ri ca l

System

i02555153

When it is possible, make a test of the charging

unit and voltage regulator on the engine, and use

wiring and components that are a permanent part of

the system. Off-engine testing or bench testing will

give a test of the charging unit and voltage regulator

Battery -

Test

operation. This testing will give an indication of

needed repair. After repairs are made, perform a test

in order to prove that the units have been repaired to

the original c ondition of operation.

Most of the tests of the electric al system can be done

on the engine. The wiring insulation must be in good

condition. The wire and cable connections must be

clean, and both components must be tight.

Test

Tools

For

The

Charging

System

Never disconnect any charging unit circuit or bat-

tery circuit cable from the battery when the charg-

ing unit is operated. A spark can cause an explo-

sion from the flammable vapor mixture of hydro-

gen and oxygen that is released from the elec-

trolyte through the battery outlets. Injury to per-

sonnel can be the result.

The battery circuit is an electrical load on the charging

unit. The load is variable because of the condition of

the charge in the battery.

NOTICE

The charging unit will be damaged if the connections

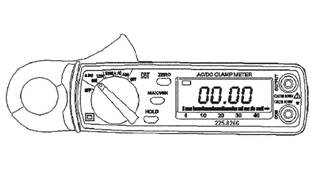

Illustration 51

Typical example of an ammeter

g01012117

between the battery and the charging unit are broken

while the battery is being charged. Damage occurs

because the load from the battery is lost and because

there is an increase in charging voltage. High voltage

will damage the charging unit, the regulator, and other

electrical components.

See Special Ins truction, SEHS7633, “Battery Test

Procedure” for the correct procedures to use to

test the battery. This publication also contains the

specifications to use when you test the battery.

i02554905

Charging System - Test

The condition of charge in the battery at each

regular inspection will show if the charging system is

operating correctly. An adjustment is necessary when

the battery is constantly in a low condition of charge

or a large amount of water is needed. A large amount

of water would be more than one ounce of water per

a cell per a week or per every 100 service hours.

The ammeter is a self-contained instrument that

measures electric al currents without breaking

the circuit and without disturbing the conductor’s

insulation.

The ammeter contains a digital display that is used

to monitor current directly within a range between 1

ampere and 1200 amperes. The multimeter should

be used under only one condition:

• the readings are less than 1 ampere.

A lever opens the ammeter’s jaws over a conductor.

The conductor’s diameter can not be larger than

19 mm (0.75 inch).

The spring loaded jaws clos e around the conductor

for measuring the current. A trigger switch controls

the ammeter. The trigger s witch can be locked into

the ON position or into the OFF position.

After the trigger has been working and the trigger is

turned to the OFF position, the reading appears in

the digital display for five seconds. This accurately

measures currents in areas with a limited access.

For example, these areas include areas that are

beyond the operator’s sight. For DC operation, an

ammeter contains a zero control, and batteries inside

the handle supply the power.

This document has been printed from SPI². Not for Resale

![]()

![]() KENR6231

KENR6231

55

Testing and Adjusting Section

Illustration 52

Typical example of a digital multimeter

g00283566

Electric

Starting

i02554920

System - Test

Most of the tests of the elec trical system can be

done on the engine. The wiring insulation must be

in good c ondition. The wire and cable connections

must be clean, and both components must be tight.

The battery must be fully charged. If the on-engine

test shows a defect in a component, remove the

component for more testing.

The starting system consists of the following four

components:

• Keyswitch

• Start relay

• Starting motor solenoid

• Starting motor

Trouble with the starting system could be caused

by the battery or by charging system problems. If

the battery is suspect, refer to Troubleshooting,

“Battery”. If the starting system is suspect, refer to

Troubleshooting, “Engine Will Not Crank”.

This document has been printed from SPI². Not for Resale

![]() 56

56

Index

Section

KENR6231

Index

A

Air in Fuel - Test..................................................... 23

Air Inlet and Exhaust System .......................... 12, 31

Turbocharger ..................................................... 13

Valves And Valve Mechanism............................ 13

Air Inlet and Exhaust System - Inspect.................. 31

Air Inlet Restriction............................................. 31

B

Basic Engine.................................................... 17, 47

Camshaft............................................................ 18

Crankshaft.......................................................... 18

Cylinder Block Assembly ................................... 17

Cylinder Head Assembly.................................... 18

Pistons, Rings And Connecting Rods ................ 18

Battery - Test ......................................................... 54

Belt Tension Chart ................................................. 22

C

Charging System - Test ......................................... 54

Test Tools For The Charging Sys tem................. 54

Connecting Rod Bearings - Inspect....................... 47

Cooling System ............................................... 16, 41

Cooling System - Check (Overheating) ................. 41

Cooling System - Inspect....................................... 42

Cooling System - Test............................................ 43

Checking the Filler Cap...................................... 44

Test For The Water Temperature Gauge ........... 45

Testing The Radiator And Cooling System For

Leaks................................................................ 44

Cylinder Block - Inspect......................................... 47

Cylinder Liner Projection - Inspect......................... 48

E

Electric Starting System - Test............................... 55

Electrical System............................................. 18, 54

Charging System Components .......................... 19

Engine Electrical System ................................... 19

Grounding Practices .......................................... 18

Starting System Components ............................ 20

Electronic Control System Components .................. 6

Electronic Unit Injector - Adjust ............................. 24

Electronic Unit Injector - Test................................. 24

Engine Crankcase Pressure (Blowby) - Test ......... 35

Engine Oil Pressure - Test..................................... 37

Measuring Engine Oil Pressure ......................... 37

Reason for High Engine Oil Pressure ................ 39

Reasons for Low Engine Oil Pressure............... 38

Engine Valve Lash - Inspect/Adjust ....................... 35

Valve Lash Adjustment ...................................... 36

Valve Lash Check .............................................. 35

Excessive Bearing Wear - Inspect......................... 39

Excessive Engine Oil Consumption - Inspect ........ 39

Engine Oil Leaks into the Combustion Area of the

Cylinders .......................................................... 39

Engine Oil Leaks on the Outside of the Engine .. 39

Exhaust Temperature - Test................................... 34

F

Finding Top Center Position for No. 1 Piston......... 25

Flywheel - Inspect.................................................. 50

Bore Runout (Radial Eccentricity) of the

Flywheel........................................................... 51

Face Runout (Axial Eccentricity) of the

Flywheel........................................................... 50

Flywheel Housing - Inspect ................................... 51

Bore Runout (Radial Eccentricity) of the Flywheel

Housing............................................................ 52

Face Runout (Axial Eccentricity) of the Flywheel

Housing............................................................ 51

Fuel Quality - Test.................................................. 26

Fuel System....................................................... 8, 23

Electronic Unit Injector ........................................ 11

Electronic Unit Injector Mechanism.................... 10

Fuel System Electronic Control Circuit ................ 9

Fuel System - Inspect ............................................ 23

Fuel System - Prime .............................................. 26

Fuel System Pressure - Test ................................. 27

Checking Fuel Pressure..................................... 28

Fuel Pressure Readings .................................... 28

High Fuel Press ure ............................................ 27

Low Fuel Pressure ............................................. 27

G

Gear Group (Front) - Time..................................... 28

Setting Backlash For Camshaft And Adjustable

Idler Gear ......................................................... 29

General Information................................................. 4

Cold Mode Operation........................................... 5

Starting the Engine .............................................. 5

I

Important Safety Information ................................... 2

Increased Engine Oil Temperature - Inspec t ......... 40

L

Lubrication System .......................................... 14, 37

Lubrication System Components ....................... 14

Oil Flow In The Engine....................................... 16

This document has been printed from SPI². Not for Resale

![]() KENR6231

KENR6231

Index

57

Section

M

Main Bearings - Inspect......................................... 47

P

Piston Ring Groove - Inspect................................. 47

Inspect the Clearance of the Piston Ring........... 47

Inspect the Piston and the Piston Rings ............ 47

Inspect the Piston Ring End Gap....................... 47

S

Systems Operation Sec tion ..................................... 4

T

Table of Contents..................................................... 3

Testing and Adjusting ............................................ 22

Testing and Adjusting Section ............................... 22

Turbocharger - Inspect .......................................... 32

Inspection of the Compressor and the Compressor

Housing............................................................ 33

Inspection of the Turbine Wheel and the Turbine

Housing............................................................ 33

V

Vibration Damper - Check ..................................... 53

W

Water Pump - Test ................................................. 46

Water Temperature Regulator - Test ..................... 45

This document has been printed from SPI². Not for Resale

![]() 58

58

Index

Section

KENR6231

This document has been printed from SPI². Not for Resale

![]() KENR6231

KENR6231

Index

59

Section

This document has been printed from SPI². Not for Resale

Copyright © 2005 Perkins Engines Company Limited

All Rights Reserved

Printed in U.K.

This document has been printed from SPI². Not for Resale