Perkins3012柴油發動機威爾遜P850E柴油發電機配件交流充電發電機

詳細描述

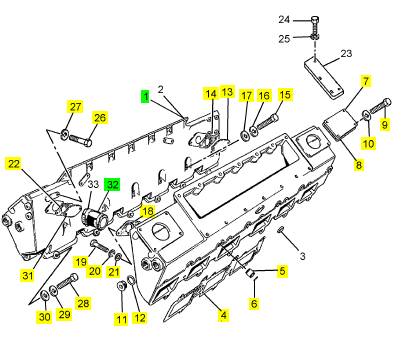

項目 零配件號碼 最近的部分號碼 描述

1 CV12081/2 2 CV12081/2 進氣岐管

4 CV20233 4 CV20233 密封墊 - IND 的岐管

5 CV507 12 CV507 線橋

6 ST10928 24 ST10928 密封O型圈

7 CV12997 2 CV12997 切片板

8 CV19492 2 CV72491 密封墊

9 2314 C045 4 2314 C045 固定螺釘

10 2134 A008 4 2134 A008 墊圈

11 ST20133 8 ST20133I 栓塞

12 ST49891 8 ST49891 墊圈

13 CV13201 2 CV13201 切片板 U11497X

14 CV20379 2 CV20379 密封墊 U11497X

15 ST43563 12 ST43563 螺拴

16 2134 A010 12 2134 A010 墊圈

17 2131 A010 12 2131 A010 墊圈

18 CV20379 1 CV20379 密封墊 U11497X

19 2314 C045 8 2314 C045 固定螺釘 U11497X

20 2134 A008 8 2134 A008 墊圈 U11497X

21 2131 A008 8 2131 A008 墊圈 U11497X

22 CV20379 1 CV20379 密封墊 U11497X

26 ST44452 2 ST44452 固定螺釘

27 ST49940 2 ST49940 墊圈

28 2314 C053 28 2314 C053 螺旋

29 2134 A010 28 2134 A010 墊圈

30 2131 A010 28 2131 A010 墊圈

31 CV13201 2 CV13201 切片板 U11497X U9736W

32 U5MH0050 1 U5MH0050 水管裝備 U9735W

項目 零配件號碼 最近的部分號碼 描述

1 CV13851 1 CV13851 進氣岐管

3 CV20211 2 CV20211I 密封墊

4 CV13852 1 CV13852 進氣岐管

6 ST20133 2 ST20133I 栓塞

7 ST49891 2 ST49891 墊圈

8 2314 C045 28 2314 C045 固定螺釘

9 2134 A008 28 2134 A008 墊圈

10 2131 A008 28 2131 A008 墊圈

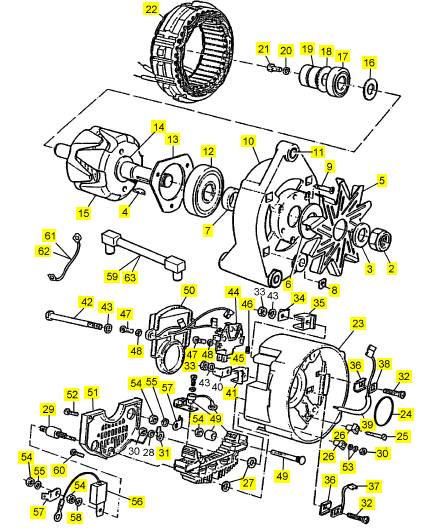

項目 零配件號碼 最近的部分號碼 描述

1 OD20798 1 CV70291 交流充電發電機

項目 零配件號碼 最近的部分號碼 描述

2 OD20441 1 OD20441 螺帽

3 OD21655 1 OD21655 墊圈

3 OD17226 1 OD21655 墊圈

4 OD17253 1 OD17253 鍵

5 OD19835 1 OD19835 風扇

6 OD19797 1 OD19797 墊圈

7 OD20543 1 OD20543 距離塊

8 OD20838 4 OD20838 螺帽

9 OD20839 3 OD20839 螺旋

10 OD20841 1 OD20841 殼

11 OD20840 1 OD20840 襯套

12 OD19798 1 OD19798 滾珠瓦

13 OD20842 1 OD20842 承件

14 OD20843 1 OD20843 距離塊

15 OD19800 1 OD19800R 轉子

(15) OD19800R 1 OD19800R 轉子

16 OD20844 1 OD20844 距離塊

17 OD19799 1 OD19799 滾珠瓦

18 OD20845 1 OD20845 轉向裝置

19 OD20846 1 OD20846 圈

20 OD20847 1 OD20847 墊圈

21 OD20848 1 OD20848 螺旋

22 OD19778 1 OD19778 固定子

23 OD20895 1 OD20895 殼

24 OD20849 1 OD20849 密封O型圈

25 OD20850 2 OD20850 螺旋

26 OD20851 2 OD20851 絕緣體

27 OD20852 2 OD20852 間隔器

28 OD20847 1 OD20847 墊圈

29 OD20854 2 OD20854 終點

30 OD20855 2 OD20855 螺帽

31 OD20856 1 OD20856 終點

32 OD20857 2 OD20857 終點

33 OD19784 2 OD19784 螺帽

34 OD20858 1 OD20858 終點

35 OD20859 1 OD20859 守衛

36 OD20860 2 OD20860 終點

37 OD20861 1 OD20861 纜

38 OD20862 1 OD20862 纜

39 OD20863 1 OD20863 鞘

40 OD20864 1 OD20864 終點

41 OD20866 1 OD20866 守衛

42 OD20867 4 OD20867 螺拴

43 OD19785 6 OD19785 墊圈

44 OD20868 1 OD20868 夾持工具

45 OD19442 2 OD19442 刷

46 OD20869 2 OD20869 彈簧

47 OD20870 4 OD20870 螺旋

48 OD20847 4 OD20847 墊圈

49 OD20871 1 OD20871 整流器

50 OD20896 1 OD20896 調整器

51 OD20872 1 OD20872 蓋

52 OD20873 2 OD20873 螺旋

53 OD20874 2 OD20874 墊圈

54 OD20875 4 OD20875 螺帽

55 OD20876 3 OD20876 墊圈

56 OD20877 1 OD20877 電容器

57 OD20878 2 OD20878 終點

58 OD20879 2 OD20879 墊圈

59 OD20880 1 OD20880 振動乘用馬

60 OD20881 1 OD20881 螺旋

61 OD20897 1 OD20897 纜

62 OD20898 1 OD20898 鞘

63 OD20899 1 OD20899 襯套

Crankshaft gear - idler gear for lubricating oil pump

Crankshaft gear - idler gear for lubricating oil pump

15

Clearanc e (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,20 mm (0.004 to 0.008 in)

Idler gear for lubricating oil pump - gear of lubricating oil pump

Clearanc e (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,10 to 0,39 mm (0.004 to 0.015 in)

Idler gears on axles

Main idler gear (A)

Bore of gear (new) (A1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,000 to 50,025 mm (1.9685 to 1.9695 in)

Diameter of bush (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,089 to 50,127 mm (1.9720 to 1.9735 in)

Interference (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,064 to 0,127 mm (0.0025 to 0.0049 in)

Bore of bush (new) (A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44,983 to 45,034 mm (1.7709 to 1.7729 in)

Axle diameter (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44,910 to 44,950 mm (1.7681 to 1.7697 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,033 to 0,124 mm (0.0013 to 0.0048 in)

Permissible worn clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,199 mm (0.0078 in)

Double idler gear (B)

Bore of gear (B1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,000 to 50,025 mm (1.9685 to 1.9695 in)

Diameter of bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,089 to 50,127 mm (1.9720 to 1.9735 in)

Interference (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,064 to 0,127 mm (0.0025 to 0.0049 in)

Bore of bush (B2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44,983 to 45,034 mm (1.7709 to 1.7729 in)

Diameter of axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44,910 to 44,950 mm (1.7681 to 1.7697 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,033 to 0,124 mm (0.0013 to 0.0048 in)

Permissible worn clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,199 mm (0.0078 in)

A

144

B

145

Perkins Engines Company Limited

102

This document has been printed from SPI². Not for Resale

15

15

Idler gear for coolant pump (A)

Bore of gear (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,000 to 34,025 mm (1.3385 to 1.3395 in)

Diameter of bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,087 to 34,125 mm (1.3420 to 1.3435 in)

Interference (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,062 to 0,125 mm (0.0024 to 0.0049 in)

Bore of bush (A2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,985 to 30,112 mm (1.1805 to 1.1855 in)

Diameter of axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,947 to 29,960 mm (1.1790 to 1.1795 in)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,025 to 0,165 mm (0.001 to 0.006 in)

Idler gear for oil pump (B)

Bore of gear (B1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,000 to 34,025 mm (1.3385 to 1.3395 in)

Diameter of bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34,087 to 34,125 mm (1.3420 to 1.3435 in)

Interference (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,062 to 0,125 mm (0.0024 to 0.0049 in)

Bore of bush (B2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,985 to 30,112 mm (1.1805 to 1.1855 in)

Diameter of axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29,947 to 29,960 mm (1.1790 to 1.1795 in)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,025 to 0,165 mm (0.001 to 0.006)

B

147

A

146

103

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

End float of idler gears

Refer to the illustrations (A and B) on page 102.

Main idler gear (A)

15

Length of axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56,150 to 56,200 mm (2.2106 to 2.2126 in)

Width of hub (A3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,875 to 51,000 mm (2.0029 to 2.0079 in)

Thicknes s of thrust washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,450 to 2,500 (0.0965 to 0.0984

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *0,100 to 0,425 mm (*0.004 to 0.017 in)

Double idler gear (B)

Length of axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56,150 to 56,200 mm (2.2106 to 2.2126 in)

Width of hub (B3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50,875 to 51,000 mm (2.0029 to 2.0079 in)

Thicknes s of thrust washers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,450 to 2,500 mm (0.0965 to 0.0984 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *0,100 to 0,425 mm (*0.004 to 0.017 in)

* These dimensions are relevant if the thrust

was hers are not completely flat

Caution: The thrust washers must be renewed if there is a reduction in the size of the grooves in the thrust

faces and the depths of the grooves are less than the nominal depth of 0,18 to 0,38 (0.007 to 0.015 in).

Refer to the illustrations (A and B) on page 103.

Idler gear of coolant pump (A)

Length of axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35,200 to 35,300 mm (1.3858 to 1.3897 in)

Width of hub (A3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32,450 to 32,500 mm (1.2775 to 1.2795 in)

Thickness of thrust washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,450 to 2,500 mm (0.0965 to 0.0984 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,200 to 0,400 mm (0.0078 to 0.0157 in)

Idler gear of lubricating oil pump (B)

Length of axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35,200 to 35,300 mm (1.3858 to 1.3897 in)

Width of hub (B3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32,450 to 32,500 mm (1.2775 to 1.2795 in)

Thickness of thrust washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,450 to 2,500 mm (0.0965 to 0.0984 in)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,200 to 0,400 mm (0.0078 to 0.0157 in)

Perkins Engines Company Limited

104

This document has been printed from SPI². Not for Resale

16

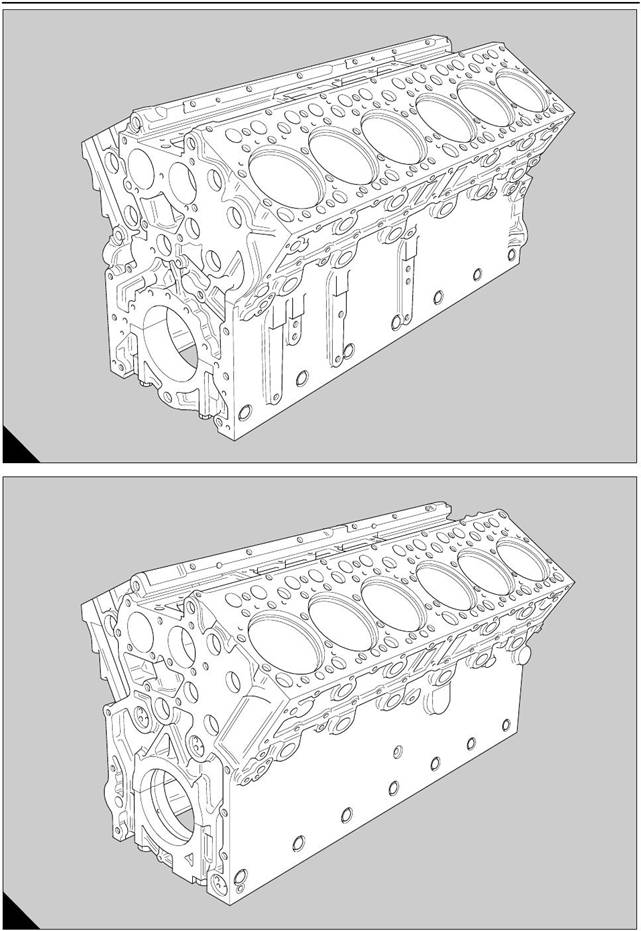

Crankcase and cylinder liners

General description

16

The crankcase (A and B) is a monobloc casting made

from high quality cast iron. The casting is dipped in a

special sealing compound to prevent contamination

and to seal all surfaces which are not machined. The

first illustration (A) shows the front of the crankcase

and the second illustration (B) shows the rear of the

crankcase.

The top of the crankcase has two banks of six

cy linders which make a ’V’ arrangement at an

included angle of 60 degrees. The cylinder banks are

not symmetrical on the crankcase and ’B’ bank is

nearer to the front of the engine. The bores of the

cy linders are machined to receive dry cylinder liners.

Galleries in the casting of the cylinder block supply a

flow of coolant around each c ylinder bore. Small

holes are drilled through each flame face to supply

coolant to the cylinder heads.

The crankcase has housings for seven main

bearings. Each assembly of the main bearings is

retained by a bearing cap made from a steel forging.

The bearing c aps at the centre and at each end of the

engine are fitted with four bolts. Each of the remainder

of the bearing caps are assembled with two bolts.

To ensure that the bearing caps are rigid, side bolts

are fitted through the side walls of the crankcase into

location pads on each side of the bearing caps. All oil

galleries are drilled to ensure that the bores are

accurate and clean.

The twelve dry liners are a fine clearance fit in the

crankcase. They have flanges at the upper ends and

are retained in their respective cylinder bores by the

four cylinder heads.

Each liner is made of cast iron by a centrifugal

process. The degree of hardness is varied along its

length and the internal diameter is machined by

special processes to obtain a surface finish which will

reduce wear and consumption of oil. The upper face

of each bank of cylinders has bores for 24 tappets.

The camshaft bearings are rolled bushes, of the split

type, and are pre-finished. They have steel bac ks

and bearing surfac es of lead bronze. The bearings do

not need normally a special procedure except to

ensure that they are cleaned thoroughly during the

overhaul.

Perkins Engines Company Limited

105

This document has been printed from SPI². Not for Resale

16

16

A

254

B

255

Perkins Engines Company Limited

106

This document has been printed from SPI². Not for Resale

![]()

|

Crankcase

a build stand

Special tools:

Strap wrench, 21825 825

16-1

7 Disconnect and remove the exhaust pipes.

8 Disconnect the electrical system between the stop

solenoid, the coolant temperature switch and the oil

pressure switch, and the main control panel.

9 Remove the radiator, operation 21-1.

10 Fit the lift plate CV 8012 to the flywheel housing

with two bolts and the spring washers.

11 Use the universal lift adaptor VP 8364 and a

suitable hoist to hold the assembly of the engine.

Build stand - engine VP 5908 which also includes:

Mounting brackets - crankcase

’B’ bank rear VP 5597

’A’ bank rear VP 5598

’A’ bank front VP 6836

’B’ bank front VP 6837

Universal lift adaptor VP 8364

Lift plate CV 8012

To fit to a build stand

To obtain access to the crankcase and further main

components, the engine must be disconnected from

its driven unit and fitted in a build stand. Instructions

to disconnect the driven unit are to be found in the

publication of the relevant manufacturer. To fit the

engine in a build stand, proceed as follows:

1 Disconnect the batteries.

2 Close the valves and disconnect the pipes for the

fuel supply and the fuel return. Remove and discard

the two filter canisters.

3 To drain the cooling system, remove the drain plugs

from the radiator, from the outlet pipe of the coolant

pump, from the front of ’A’ bank and from the rear of

’B’ bank of the crankcase.

4 Drain the lubricating oil from the engine by the

removal of the drain plug from the base of the sump.

5 Drain the engine lubricating oil from the heat

exchanger by the removal of the drain plug at the rear

end. Put a container below the filter canisters to

receive the oil which drains from the heat exchanger.

6 Lubricating oil which remains in the heat exchanger

can be drained by the removal of the three filter

canisters. Use the strap wrench, 21825 825, to

remov e and discard the filter canisters.

12 Disconnect the support brackets from the flywheel

housing, and the front mountings from the base

frame.

If not relevant to the job, the front mountings may be

retained on the fan adaptor.

13 Lift the assembly of the engine from the mountings

and lower it on to the floor of the workshop with

suitable wooden supports beneath the flywheel

housing.

Before the engine is fitted in the build stand and

subsequently dismantled, clean it thoroughly and

ensure that the cooling and lubrication systems are

drained completely.

14 Remove the air filters and their support brackets,

and the inlet ducts for the turbochargers.

15 If relevant to the job, releas e the three bolts which

retain the starter motor. Withdraw the starter motor.

16 Remove the fan, operation 21-8.

17 If relevant to the job, remove the fan belts and the

tensioner pulley, operation 21-9.

18 If relevant to the job, remove the crankshaft pulley,

the damper and the alternator pulley, operation 14-1.

Caution: The damper is a heavy component and

must not be allowed to fall during removal, because

distortion of the casing can prevent its correct

operation.

107

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

19 Remove the front covers of the coolant galleries

19 Remove the front covers of the coolant galleries

and fit the four mounting brackets to the crankcase as

To remove from a build stand

16

follows:

l VP 6836:

l VP 6837:

l VP 5598:

l VP 5597:

at the front of ’A’ bank over the front

coolant gallery

at the front of ’B’ bank over the front

coolant gallery

on the bosses at the rear of ’A’ bank

on the bosses at the rear of ’B’ bank

1 If relevant, fit the lift plate CV 8012 to the flywheel

housing with two bolts and spring washers.

2 Remove the eight bolts and nuts, whic h retain the

mounting brackets to the arms of the build stand, and

use the universal lift adaptor VP 8364 and a suitable

hoist to remove the engine from the build stand.

Lower the engine on to the floor of the workshop with

suitable wooden s upports beneath the flywheel

housing.

Caution: Ensure that the plug in the boss at the rear

of ’A’ bank has been removed before the mounting

bracket VP 5598 is fitted.

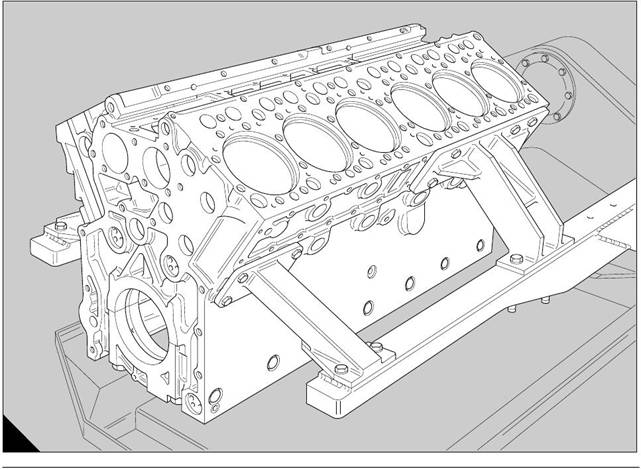

20 Use the lift adaptor VP 8364 to put the engine in

the build stand VP 5908 with the flywheel at the outer

end. Fit the eight bolts, which retain the mounting

brackets, through the arms of the build stand as

shown (A), fit the nuts and tighten sec urely. Remove

the universal lift adaptor.

3 Clean thoroughly the blanking plug which was

removed from the rear of ’A’ bank. Apply some

’Loc tite 542’ to the blanking plug and ensure that it is

fitted to the boss when the mounting bracket VP 5598

is removed.

4 Remove the four mounting brackets from the

crankcase and use new joints to fit the front covers of

the coolant galleries.

5 If relevant, fit the crankshaft pulley, the damper and

the alternator pulley, operation 14-1.

A

256

Perkins Engines Company Limited

108

This document has been printed from SPI². Not for Resale

|

6 If relevant, fit the assembly of the tensioner pulley

and fit loosely the fan belts, operation 21-9.

7 Fit the fan and tighten the fan belts, operation 21-9.

8 If relevant, fit the front mountings to the fan adaptor.

9 Fit the starter motor and retain it with the three

bolts.

10 Fit the inlets of the turbochargers, the air filters

and their support brackets.

11 Use the universal lift adaptor VP 8364 to lift the

assembly of the engine over the base frame and

lower carefully the engine. Connect the support

brackets to the flywheel housing and the front

mountings to the base frame. Remove the lift

adaptor.

12 Fit the radiator, operation 21-1.

13 Connect the electrical system between the main

control panel and the stop solenoid, the coolant

temperature switch and the oil pressure switch.

14 Install and connect the exhaust pipes.

15 Fit the drain plugs in the base of the lubricating oil

sump and at the rear end of the heat exchanger.

16 Fill the filter canisters with clean engine lubricating

oil and fit them on to the adaptors of the bracket for

the filter head, until the seal on each canister is just in

contact with its face. Tighten by hand each canister a

further 1 /4 turns. Do NOT overtighten.

17 If the engine lubricating oil can be used again,

return it to the sump of the engine and fill the sump

with new and clean oil to the ’Full’ mark on the

dipstick, if necessary.

|

|

bank and to the rear of ’B’ bank of the crankcase, to

the outlet pipe of the coolant pump and to the radiator.

Check that the drain plugs are secure and fill the

cooling system. Add more coolant, of the same

specification as that already in use, if neces sary.

Check for leakage in the system.

19 Fit two new fuel filter canisters on to the adaptors

of the filter head, until the seal on each canister is just

in contact with its face. Tighten by hand each canister

the pipes and open the valves for the fuel supply and

the fuel return. Check for leakage in the sys tem.

20 Release the two bolts and the spring washers

which retain the lift plate CV 8012 on the flywheel

housing and remove the lift plate.

21 Connect the engine to its driven unit, in

accordance with the instructions which are to be

found in the publication of the relevant manufacturer.

22 Connect the batteries.

109

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() To dismantle and to assemble

To dismantle and to assemble

16-2

11 Remove the fan adaptor, operation 21-10.

16

Special tools:

Retainers, 21825 844

Lift adaptor – crankcase

VP 9967 Dial gauge and holder, 21825 786

Check plate, 21825 787

To dismantle

1 Fit the assembly of the engine in the build stand,

operation 16-1.

It is recommended that the smaller items, (for

example, low-pressure fuel pipes, clips, brackets ,

etc.) have labels to indicate their location and their

purpose, and are put in containers with relevant

engine parts.

2 Disconnect and remove the coolant pipes from

between the coolant gallery of 'A' bank, the coolant

pump and the heat exchanger.

3 Disconnect and remove the coolant pipe from

between the front cover of the coolant gallery on 'B'

bank and the outlet of the heat exchanger.

4 Disconnect and remove the pipe between the

coolant pump and the thermos tat housings.

5 Remove the fuel injectors, operation 20-7.

6 Remove the fuel injection pump, operation 20-8.

7 Remove the cylinder heads, operation 12-9.

8 Remove the two blanking plates and the mounting

for the fuel injection pump from the 'V' of the

crankcase.

9 Lift out the tappets and make temporary marks to

indicate their positions when the crankcase is

assembled.

10 Hold the cylinder liners with the retainers, 21825

844.

12 Remove the flywheel and the flywheel housing,

operation 22-4.

13 Remove the timing case, operation 15-5.

14 Remove the camshafts, operation 17-1.

15 Remove the lubricating oil sump, operation 19-1

or, for new engines, operation 19-5.

16 For early engines, remove the sump adaptor,

operation 19-3.

17 Remove the lubricating oil pump, operation 19-7.

18 Remove the assemblies of the pistons and the

connecting rods, operation 13-3 paragraph 8.

19 Remove the crankshaft, operation 14-4 paragraph

12 to 14.

20 Remove the piston cooling jet assemblies.

21 Remove the retainers. Withdraw carefully each

liner and put it with its own assembly of piston and

connecting rod.

22 Remove the rear covers of the coolant galleries,

the fuel filter head, operation 20-3, and the heat shield

for the filter head.

23 If the camshaft bearings are to be renewed, the

cup plugs at the front ends of the camshaft bores

must be removed.

24 If the crankcase is to be tested under pressure,

remove the eight bolts and nuts, which retain the

mounting brackets to the arms of the build stand. Use

a hoist and a suitable rope sling to remove the

crankcas e from the build stand.

25 Remove the four mounting brackets from the

crankcas e.

Perkins Engines Company Limited

110

This document has been printed from SPI². Not for Resale

16

16

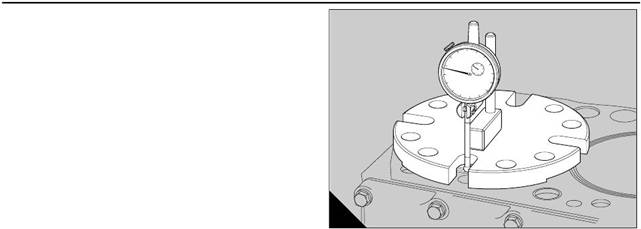

To assemble

1 If the crankcase has been tested under pressure

and it is acceptable, fit the four mounting brack ets to

the crankcase. Use a hoist and a suitable rope sling

to lift the crankcase and put it in the build stand VP

5908. Ensure that the end of the crankcase to which

the timing case is fitted is furthest from the build

stand.

Note: The weight of the crankcase is approximately

620 kg (1367 lb).

2 Fit each piston cooling jet assembly onto the

relevant studs in the crankcase, fit the spring washers

and nuts on the studs and lightly tighten the nuts.

A

257

Caution:

Check that the top faces of the banks of the

cylinders and all of the cylinder liners are clean. The

number of its respective cylinder is etched on each

cylinder liner, and the numbers should be toward the

centre of the engine when the cylinder liners are

ins erted.

3 Insert each cylinder liner in its respective cylinder

bore. Use the check plate, 21825 786, and the dial

gauge and holder, 21825 787, to check the protrusion

of the cylinder liners above the top faces of both

banks of cylinders. Ensure that the check plate and

the holder for the dial gauge are clean.

4 Put the check plate over the first cylinder liner and

put the holder of the dial gauge on the checking plate.

Put the button of the dial gauge on the top face of the

bank of cylinders and set the dial gauge to zero (A).

Caution: The check plate may be held on the top

face of the bank of cylinders by two of the bolts which

retain a cylinder head, if the top face is not horizontal.

111

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

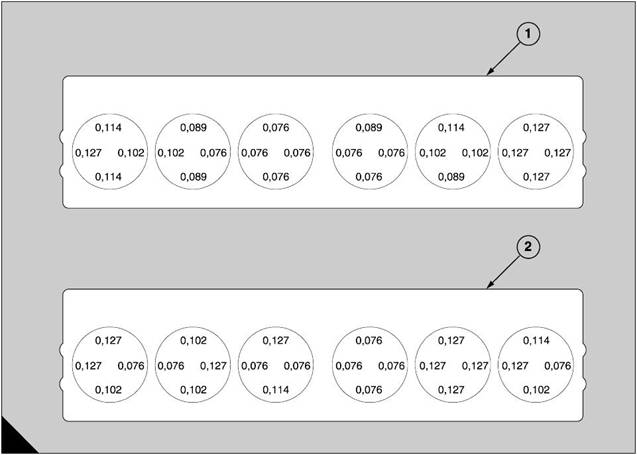

5 Put carefully the button of the dial gauge onto the

5 Put carefully the button of the dial gauge onto the

top face of the flange of the first cylinder liner, at four

different locations. Each correct location for the

button is shown (A). Make a note of the deflection,

from zero, for each location.

6 Move the check plate to the other cylinder liners in

rotation and check their protrusions. Compare the

readings which have been obtained with the

protrusions shown (A).

Caution:

l The protrusion for each cylinder liner must be

between 0,076 mm and 0,127 mm (0.003 in and

0.005 in).

l The variation of protrusion around the

circumference of a liner must not exceed 0,025

mm (0.001 in).

l The variation of protrusion between the nearest

points of two cylinder liners which are next to each

other must not exceed 0,025 mm (0.001 in).

l The maximum difference in the protrusions under

one cylinder head must not exceed 0.051 mm

(0.002 in).

l Banks shown as A1 will be acceptable. Banks

shown as A2 are not acceptable.

16

7 Renew a cylinder liner if its protrusion is not correct.

Inspect the seat of the flange of the new cylinder liner,

operation 16-5. Check its protrusion also.

8 When their protrusions have been checked, make

temporary marks to indicate the exact position of each

flange in the crankcase and remove the cylinder

liners. Immediately before the work proceeds, clean

the top of each bank of cylinders, degrease and dry

the cylinder liners and the recesses for the flanges of

the cylinder liners.

9 Apply a bead of ’Hylomar PL 32/M’ (medium grade)

to the seat under the flange of each c ylinder liner.

Remove the surplus from the faces on the side. Allow

the compound to partially dry, align the temporary

marks and insert, without rotation, each cylinder liner

in its bore in the crankcase. Do not subsequently

allow the ’Hylomar’ seal to be broken.

10 Use the bolts of the cylinder heads to fit eight

retainers, 21825 844, to ensure that the cylinders

liners remain in their positions when the assemblies of

the pistons and the connecting rods are fitted.

A

130

Perkins Engines Company Limited

112