Perkins3012柴油發動機威爾遜P850E柴油發電機配件水泵

詳細描述

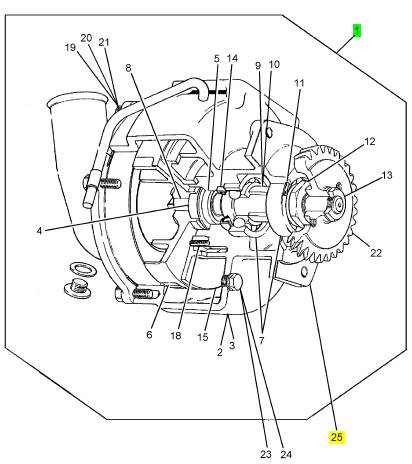

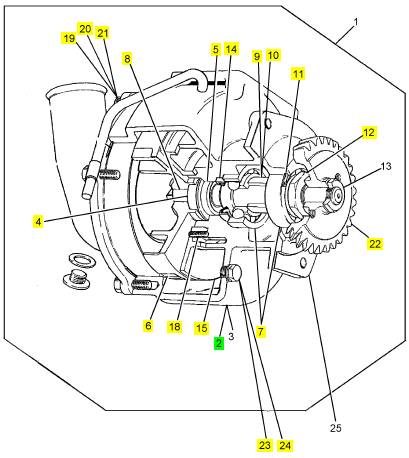

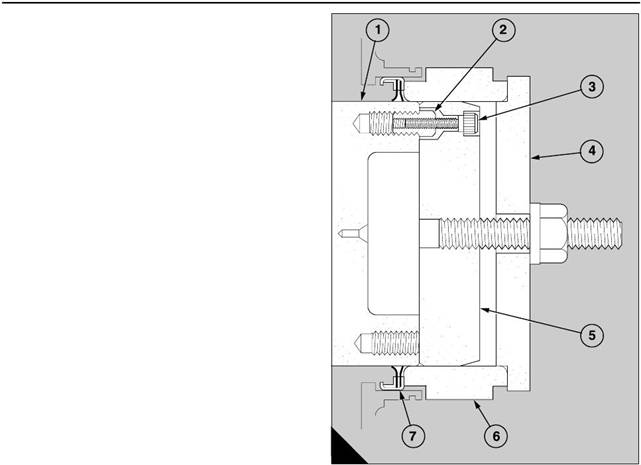

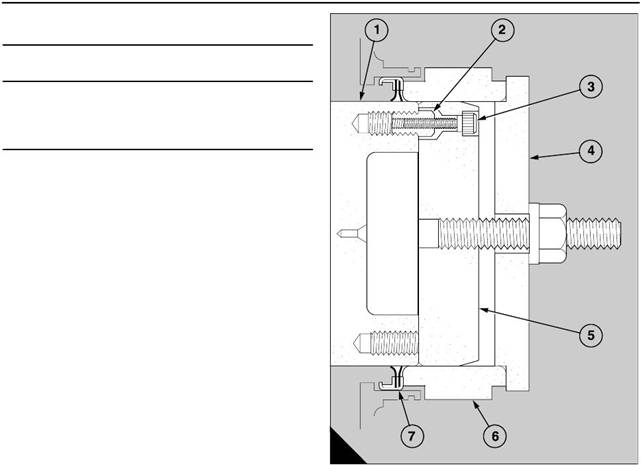

項目 零配件號碼 最近的部分號碼 描述

ST46076 1 ST46076I 栓塞

ST49851 1 ST49851 墊圈

1 CV14573/2 1 CV14573/2 水泵

25 CV1243 1 CV20206 密封墊

26 CVK533 1 CVK533 修理裝備 - 水的泵

27 CVK534 1 CVK534 修理裝備 - 水的泵

項目 零配件號碼 最近的部分號碼 描述

2 CV14576 1 CV14576 套

4 CV14309 1 CV20055 密封

5 CV14310 1 CV14310 計數器板

6 CV14574 1 CV14574 動葉輪

7 OE1376 2 OE1376 滾珠瓦

8 CV14575 1 CV14575 橋

9 CV1236 1 CV1236 間隔器

10 CV14053 1 CV14053 填隙用木片

11 ST48993 1 2721351 CIRCLIP

12 CV2235 1 CV2235 螺帽

13 CV2234 1 CV2234 螺帽

14 CV1234 1 CV1234 密封

15 CV1233 1 CV1233 圓盤

16 ST10965 1 ST10965 密封O型圈

17 CV5515 1 CV5515 肘管

18 ST46955 1 ST46955 螺旋

19 ST43502 5 ST43502 螺拴

20 ST43160 5 2134 A008 墊圈

21 ST43056 5 2131 A008 墊圈

22 CV1227 1 CV1227 水泵傳動機構

23 ST46076 1 ST46076I 栓塞

24 ST49891 1 ST49891 墊圈

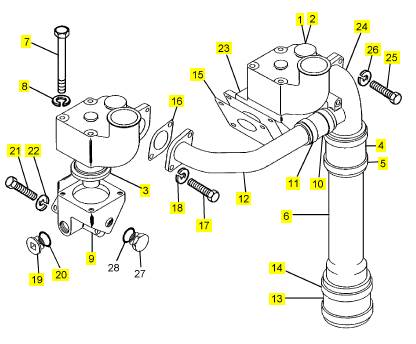

項目 零配件號碼 最近的部分號碼 描述

1 CV14258 2 CV14258 節溫器殼

2 CV13582 2 CV13582 密封

3 CV20747 2 CV20747 節溫器

4 ST91232 1 ST91232 水管

5 ST46411 2 ST46411 夾

6 CV14269 1 CV14269 水管

7 ST43515 8 ST43515 螺拴

8 2134 A008 8 2134 A008 墊圈

9 CV18442 1 CV18442 承接器

10 ST91204 1 ST91204 水管

11 ST46408 2 ST46408 夾

12 CV14263 1 CV14263 水管

13 ST91239 1 ST91239 水管

14 ST46412 2 ST46412 夾

15 CV19492 2 CV72491 密封墊

16 CV20383 2 CV20383 密封墊

17 2314 C045 3 2314 C045 固定螺釘

18 2134 A008 3 2134 A008 墊圈

19 ST20106 2 ST20106 栓塞

20 ST49856 2 ST49856 墊圈

21 ST43502 8 ST43502 螺拴

22 2134 A008 8 2134 A008 墊圈

23 CV14273 1 CV14273 承接器

24 CV14261 1 CV14261 連接

25 ST43511 1 ST43511 螺拴

26 2134 A008 1 2134 A008 墊圈

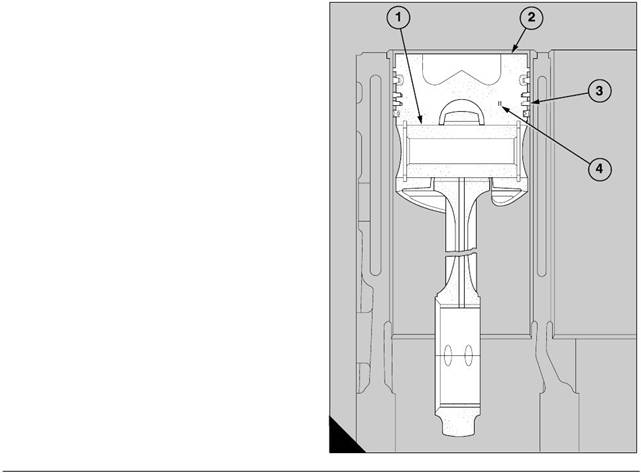

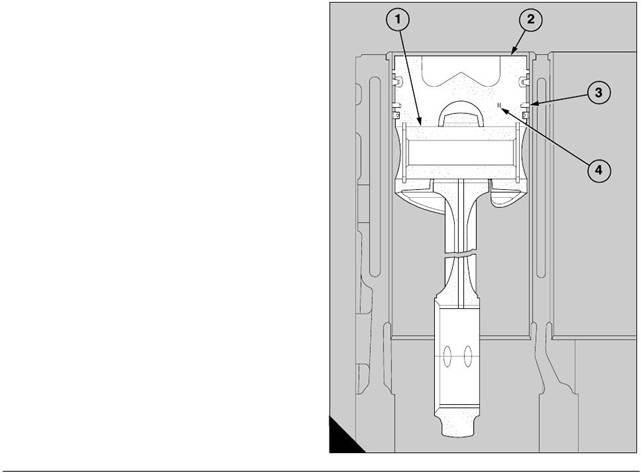

3 Insert the small end of the connecting rod into the

piston, and ensure that the cut-out in the lower wall of

the piston is on the opposite side to the larger c hamfer

in the bore of the big end.

4 Slide the gudgeon pin into the piston through the

small end bush and fit the second circlip into its

groove.

Caution: When the big-end bolts are to be fitted, the

flat surface, which is machined on the shoulder at the

centre of each bolt, must be away from the bore of the

big end. The half bearings will then engage correctly

in the bore of the connec ting rod. The shoulders of

new bolts do not have the flat surfaces and special

fitting instructions are not needed for them.

13

Perkins Engines Company Limited

69

This document has been printed from SPI². Not for Resale

![]() 13

13

Piston rings

To remove and to fit

Special tools:

Ring expander, 21825 793

13-5

To remove

1 Put the top face of the piston on the bench and use

the ring expander, 21825 793, with the location ring,

21825 874, to remove carefully each piston ring. Only

increase the ring gaps enough to ensure that the ends

of the rings do not damage the piston. Lift out the coil

spring from the groove for the oil control ring. Keep

the rings with their relevant piston.

To fit

1 Put the top face of the piston on the bench and

lubricate the grooves for the piston rings. Use the ring

expander, 21825 793, to fit carefully each piston ring

in the sequence given below. Only increase the ring

gaps enough to ensure that the ends of the rings do

not damage the piston.

2 Remove the coil spring from its oil control ring and

fit it around the bottom piston ring groove, with the

latch pin inside both ends of the spring, before the oil

control ring is fitted to the piston. Ensure that the

piston ring gap is at 180° to the latch pin.

The sequenc e of the assembly of the rings is:

Top - Barrel faced molybdenum

surface

Second - Chromium plated surface,

counterbore toward top of

piston

Third - 'Ferrox' treated surface,

counterbore toward top of

piston

Bottom - Composite chromium plated

oil control ring

70

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() Piston and rings

Piston and rings

Connecting rod

13

To inspect

13-6

To inspect

13-7

1 Soak the components in a solvent, such as ’Maxan’

or ’Ardrox 667’, to remove the carbon. Wash the

components in clean water and dry them with

compressed air.

2 Inspect the piston for wear, deep sc ratches, cracks

and further damage. Check that the wear in each

piston ring groove does not exceed the permissible

limits. If necessary, check the grooves by the use of

new piston rings.

3 Inspect the piston rings for wear, deep scratches

and signs of leakage. Discard the top ring if the

surface has large holes or cavities, or if there are

signs that the surface finish has started to break.

Compare the s urface with the surface of a new ring if

necessary.

4 Inspect the spring which is behind the oil control

ring. If the circumference of the spring is excessively

decreased, the spring and the oil control ring must be

renewed as a complete unit.

5 Check the gap of each piston ring in a new cylinder

liner, or in a portion of the original c ylinder liner which

is not worn. Discard a piston ring with a gap which

exceeds the limits given on page 73 or page 75.

Caution: When a new cylinder liner has been fitted,

the piston rings must also be renewed. When a new

piston ring is fitted into an original cylinder liner, the

bore of the cylinder liner must be honed or lapped to

break the glazed surface.

6 Check for cracks in the gudgeon pin and check also

its fit in the piston. The gudgeon pin should be a push

fit at 20°C (68°F). If the gudgeon pin is loose in its

bore, the assembly must be renewed.

Caution: An assembly of a piston and its gudgeon

pin must be renewed if the components do not

conform to the limits given in Fits and clearances at

the end of this section. If it is necessary to renew a

piston, it is also necessary to ensure that the

clearance is correct between the top of the new piston

and the top face of the cylinder bank by the use of the

height gauge, 21825 782, operation 13-3.

1 Clean the assembly of each connecting rod in

kerosene or a degreasing solution, and then check for

cracks in the rod, the big end cap and the big end

bolts.

Caution: It is recommended that the old bolts and

the old nuts of the assemblies of the connecting rods

should be discarded. Fit always new nuts to new

bolts and lubricate lightly the threads and the contact

faces before they are fitted to the connecting rods.

2 The bolts and the nuts of the assemblies of the

connecting rods must be inspected for signs of

distortion of the threads, for stress or for stretch, etc.

Renew all bolts which could be defective.

3 Check the small end bush for wear, for roughness

and for deep scratches. If a bush is damaged, it must

be renewed.

4 Inspect the half bearings of the big end for cracks,

for scratches and for contamination in the bearing

surfaces.

5 Check the alignment of the big end and of the small

end of the connecting rod. Do not try to correct a

connecting rod which is bent or twisted.

Perkins Engines Company Limited

71

This document has been printed from SPI². Not for Resale

13

13

Fits and clearances - Pistons and connecting rods

Pistons - 4 rings

Gudgeon pin in piston (A1)

(Gudgeon pin to be push fit at 20°C)

Bore in piston (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54,999 to 55,004 mm (2.1653 to 2.1655 in)

Gudgeon pin diameter (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54,995 to 55,000 mm (2.1652 to 2.1654 in)

Gudgeon pin in piston - clearance (new) . . . . . . . . . . . . . . . . . -0,001 to +0,009 mm (-0.00004 to +0.00036 in)

Top groove in piston

(wedge shaped for top ring CV 5907)

Diameter over 3,302 mm (0.1300 in) dia. Rollers . . . . . . . . . . . 136,073 to 135,855 mm (5.3572 to 5.3486 in)

Piston clearance at TDC (A2)

Top of piston below top face of crankcase. . . . . . . . . . . . . . . . . . . . . . . 0,310 to 0,380 mm (0.012 to 0.015 in)

(Machine top face of piston to obtain correc t clearance)

Piston rings

Clearances of piston rings in grooves (A3)

Top ring CV 5907 (wedge shaped - new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to ring gap dimensions

Second ring OE41689 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,0635 to 0,1016 mm (0.0025 to 0.0040 in)

Maximum permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,152 mm (0.006 in)

A

121

72

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

Clearances of piston rings in grooves (continued)

Refer to the illustration (A) on page 72.

13

Third ring OE 42641 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,0635 to 0,1143 mm (0.0025 to 0.0045 in)

Maximum permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,152 mm (0.006 in)

Oil control ring CV 5908 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,049 to 0,086 mm (0.0019 to 0.0034 in)

Maximum permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,152 mm (0.006 in)

Free length of coil spring (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . 423,96 to 426,34 mm (16.691 to 16.785 in)

Piston ring gaps measured with ring in new liner (A4)

Top ring CV 5907 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,50 to 0,70 mm (0.0196 to 0.0275 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,397 mm (0.055 in)

Second ring OE 41689 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,432 to 0,686 mm (0.017 to 0.027 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,524 mm (0.060 in)

Third ring OE 42641 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,432 to 0,686 mm (0.017 to 0.027 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,524 mm (0.060 in)

Oil control ring CV 5908 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,430 to 0,810 mm (0.0169 to 0.0319 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,016 mm (0.040 in)

Perkins Engines Company Limited

73

This document has been printed from SPI². Not for Resale

13

13

Pistons - 3 rings

Gudgeon pin in piston (A1)

(Gudgeon pin to be push fit at 20°C)

Bore in piston (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54,999 to 55,009 mm (2.1653 to 2.1657 in)

Gudgeon pin diameter (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54,995 to 55,000 mm (2.1652 to 2.1654 in)

Gudgeon pin in piston - clearance (new) . . . . . . . . . . . . . . . . . -0,001 to +0,014 mm (-0.00004 to +0.00055 in)

Top groove in piston

(wedge shaped for top ring CV 19329)

Diameter over 3,666 mm (0.1443 in) dia. rollers . . . . . . . . . . . . 135,155 to 135,405 mm (5.3211 to 5.3309 in)

Piston clearance at TDC (A2)

Top of piston below top face of crankcase. . . . . . . . . . . . . . . . . . . . . . . 0,310 to 0,380 mm (0.012 to 0.015 in)

(Machine top face of piston to obtain correc t clearance)

Piston rings

Clearances of piston rings in grooves (A3)

Top ring CV 19329 (wedge shaped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Refer to ring gap dimensions

Second ring CV 18638 (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,067 to 0,090 mm (0.0026 to 0.0035 in)

Maximum permissible worn c learance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,152 mm (0.006 in)

A

127

74

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

Clearances of piston rings in grooves (continued)

Refer to the illustration (A) on page 74.

13

Oil control ring CV 18639 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,048 to 0,085 mm (0.0019 to 0.0034 in)

Maximum permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,152 mm (0.006 in)

Free length of coil spring (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . 423,96 to 426,34 mm (16.691 to 16.785 in)

Piston ring gaps measured with ring in new liner (A4)

Top ring CV 18637 (wedge shaped - new) . . . . . . . . . . . . . . . . . . . . . . 0,35 to 0,55 mm (0.0138 to 0.0217 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,397 mm (0.055 in)

Second ring CV 18638 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,43 to 0,68 mm (0.017 to 0.027 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,524 mm (0.060 in)

Oil control ring CV 18639 (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,40 to 0,78 mm (0.016 to 0.031 in)

Maximum permissible worn gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,016 mm (0.040 in)

Perkins Engines Company Limited

75

This document has been printed from SPI². Not for Resale

13

13

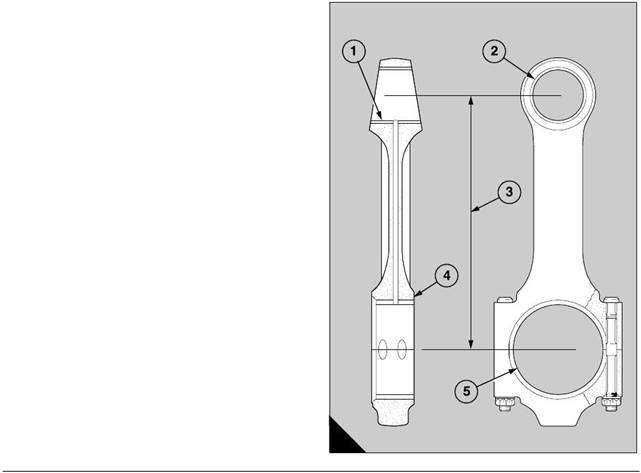

Connecting rods

Gudgeon pin in bush (A1)

Bore of bush. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55,035 to 55,050 mm (2.1667 to 2.1673 in)

(Bush pressed into position and bored to size)

Diameter of gudgeon pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54,995 to 55,000 mm (2.1652 to 2.1653 in)

Clearance (new). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,035 to 0,055 mm (0.0014 to 0.0022 in)

Permissible worn clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,067 mm (0.0026 in)

Bush in small end (A2)

Bore in connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60,00 to 60,03 mm (2.3622 to 2.3633 in)

Diameter of bush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60,072 to 60,097 mm (2.365 to 2.366 in)

Interference fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,042 to 0,097 mm (0.0017 to 0.0038 in)

Alignment of connecting rod (A3)

Parallel alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,025 mm (0.001 in)

(Meas ured between big end and small end, for each 25,40 mm (1.000 in) of test mandrel)

Distance between centres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273,05 to 272,95 mm (10.750 to 10.746 in)

End-float of big end (A4)

End-float. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,20 to 0,40 mm (0.008 to 0.016 in)

Permissible worn end-float. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,558 mm (0.022 in)

(End-float of each set of two big ends on common c rank pin)

Clearance on diameter of big end (A5)

Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,026 to 0,086 mm (0.001 to 0.003 in)

(Check that crank pin is within limits of ovality)

A

119

76

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

14

14

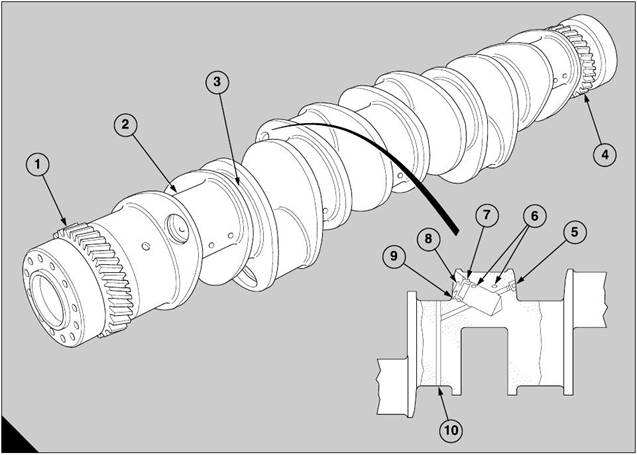

Crankshaft assembly

General description

14

Holes are drilled through the diameter of the main

journals. The holes are connected with holes in each

crank pin to supply lubricating oil to the big end

bearings of the connecting rods. The seventh main

journal at the rear of the crankshaft is not drilled.

For engines built up to build number 970208 the holes

are connected through each crankshaft web to the

reservoirs in the crank pins (A2). The oil flows to the

bearing surfaces of the crank pins from the reservoirs

The crankshaft is made from a forging of chromium

molybdenum steel. It is nitrided on all surfaces except

the tapped holes, the hole for the dowel and the end

faces at the front and the rear. The correct balance is

obtained when the crankshaft is machined, and there

is no requirement for further compensation when

assembled.

The 13 bearing s urfaces consist of seven main

journals and six crank pins. Each crank pin holds two

connecting rods.

The crankshafts of engines manufactured up to build

number 970209 have an oil reservoir in each crank

pin. Access to clean each reservoir is provided by a

steel plug (A8) which is retained by a s pring clip (A9).

The crankshafts of engines from build number

970209 have an arrangement of passages which

removes the requirement for oil reservoirs.

through two holes (A6) which are drilled in each crank

pin.

The small holes in the crankshaft webs are sealed

with special blanking plugs (A5).

The crank pin arrangement is 1 and 6, 2 and 5, 3 and

4. Each set of two crank pins is aligned 120 degrees

from the other two sets. This gives a firing order of

A6, B1, A3, B4, A5, B2, A1, B6, A4, B3, A2 and B5.

A helical gear (A4) with 45 teeth is machined around

the rear end of the crankshaft and is the primary drive

for the timing gears. The face at the rear of the

crankshaft has 16 equally spaced tapped holes to

receive the cap screws which retain the flywheel. A

dowel of the spring type is fitted in a hole in the face

to ensure an accurate alignment of the timing mark on

the flywheel.

A

199

Perkins Engines Company Limited

77

This document has been printed from SPI². Not for Resale

![]() 14

14

A helical gear (A1) with 45 teeth is machined around

the front end of the crankshaft. The gear drives the

lubricating oil pump through an idler gear. The face at

the front end is drilled and tapped for 12 equally

spaced bolts, which retain the vis cous damper and

the multiple groove pulley for the fan drive belts.

The main bearings have steel backs with bearing

surfaces of lead bronze. The bearing surfaces have

|

To remove and to fit

To remove

14-1

a fine top lay er of lead indium.

The upper half of each bearing has a central groove

for oil around the inner surface. A hole is drilled in the

centre of the groove and is aligned with a hole in the

crankcase which supplies the oil.

The lower halves of the bearings do not have

grooves.

One end of each half bearing has a location tag which

is pressed away from one edge. The tags fit in

recesses which are machined in the crankcase and in

the bearing caps.

The thrust washers have steel backs with faces of

lead bronze. They are made in two halves which are

interchangeable. Each half has a location tag at one

end. The upper halves are fitted in recesses which

are machined in the crankcase on each side of the

central main journal; the lower halves are fitted in

recesses which are machined in the bearing cap.

Lubricating oil is supplied from the central main

bearing across the face of each washer, in which

grooves are machined to assist the flow of oil.

1 Release the large lock nut on the tensioner of the

fan belts and turn the adjustment screw to loosen the

fan belts. Remove the fan belts.

2 Remov e two horizontally opposite bolts from the

crankshaft pulley. Make locally two suitable guide

studs and fit them into the bolt holes.

3 Remove the remainder of the twelv e bolts from the

crankshaft pulley. Lift away the pulley for the fan

belts, followed by the damper and then the alternator

pulley from the guide studs.

Caution: The damper is a heavy component and

must not be allowed to fall during removal, because

distortion of the casing can prevent its correct

operation.

To fit

1 Fit the guide studs into the horizontally opposite

bolt holes in the end fac e at the front of the crankshaft.

Fit the alternator pulley on the guide studs, followed

by the damper and then the pulley for the fan belts.

2 Insert ten bolts, with their spring washers, through

the bolt holes and tighten securely the assembly to

the crankshaft. Remov e the guide studs and fit the

two remaining bolts and their spring washers.

3 Tighten each bolt to 80 Nm (59 lbf ft).

78

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

14

14

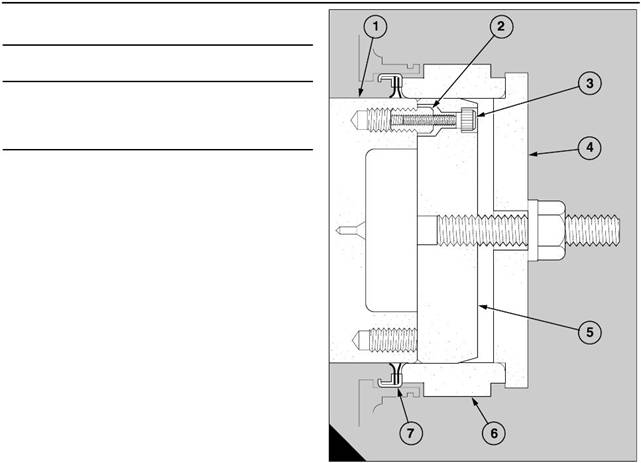

Front oil seal

To renew

Special tools:

Remover/replacer, 21825 905

14-2

To remove

1 Remove the crankshaft pulley, the damper and the

alternator pulley, operation 14-1.

2 Use the kit of the remover/replacer, 21825 905, to

remove and to replace the oil seal. Use the two short

setscrews in the kit to fit the top plate (A4) to the front

end of the crankshaft. Ensure that the counterbores

of the holes around the edge of the top plate are away

from the engine.

3 Use the centre punch in the kit, through the holes

around the edge, to either make three holes in the oil

seal, or to mark the centres in order to drill three holes

of a size which is s uitable to receive the three 40 mm

(1.5 in) long self-tapping sc rews in the kit.’

Caution: Three holes around the edge of the top

plate are marked ’A’ and three holes are marked ’B’.

Use the relevant group of holes which align centrally

A

129

with the metal of the seal.

4 Fit the three self-tapping screws through the holes

in the top plate into the holes in the seal. Do not

overtighten. Remove the setscrews which retain the

top plate and fit the three long screws of the kit.

Tighten evenly the screws against the end of the

crankshaft to pull out the seal. Remove the self-

tapping screws when the seal is withdrawn.

Perkins Engines Company Limited

79

This document has been printed from SPI². Not for Resale

14

14

To fit

1 Ensure that the crankshaft, the fan adaptor and the

oil seal are clean. Use the kit of the remover/replacer,

21825 905, to fit the new oil seal at the front end of the

crankshaft. Fit the four special studs (A2) into four

equally spaced bolt holes in the end face of the

crankshaft (A1). Tighten lightly each special stud and

hold the guide (A5) agains t the end face of the

crankshaft.

2 Insert the four cap screws (A3), through the four

small holes in the guide, into the special studs. DO

NOT tighten the cap screws.

3 Slide the collar (A6) over the guide and the

crankshaft to ensure the concentricity of the guide on

the crankshaft. Tighten the four cap screws and

remov e the c ollar.

4 Before the new oil seal (A7) is fitted, check the

guide and the crank shaft for dirt or a rough surface

finish which could damage the lip of the oil seal.

5 Apply a small amount of clean engine lubricating oil

to the guide and the flange of the crankshaft, remove

and discard the yellow inner sleeve, and slide the seal

onto the parallel section of the guide. The lip of the

seal is toward the crankcase.

6 Slide the collar onto the guide until the face of the

collar presses against the outer face of the oil seal.

Caution: This tool is used for both CV8/3008 and

46

A

129

CV12/3012 engines and the collar is marked to show

the correct assembly for each engine. It is important

that the collar is fitted correctly. For CV12/3012

engines, the edge of the shorter of the two shoulders

which are machined on the collar must be against the

oil seal.

7 Fit the top plate (A4) onto the central stud and

engage its shoulder in the collar. Lightly lubricate the

thread of the stud and also the thrust washer. Fit the

nut and the thrust washer to retain the top plate. Use

the correct spanner to tighten the nut until the larger

diameter of the collar is in contact with the face of the

housing. Remove the complete tool.

8 Fit the crankshaft pulley, the damper and the

alternator pulley, operation 14-1.

80

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

14

14

Rear oil seal

To renew

Special tools:

Remover/replacer, 21825 810

14-3

To remove

1 Remove the flywheel, operation 22-1.

2 Use the kit of the remover/replacer, 21825 810, to

remove and to replace the oil seal. Use the two short

setscrews in the kit to fit the top plate (A4) to the rear

end of the crankshaft. Ensure that the counterbores

of the holes around the edge of the top plate are away

from the engine.

3 Use the centre punch in the kit, through the holes

around the edge, to either make three holes in the oil

seal, or to mark the centres in order to drill three holes

of a size whic h is suitable to receive the three self-

tapping screws in the kit.

Caution: Three holes around the edge of the top

plate are marked ’A’ and three holes are marked ’B’.

Use the relevant group of holes which align centrally

with the metal of the seal.

A

129

4 Fit the three self-tapping screws through the holes

in the top plate into the holes in the seal. Do not

overtighten.

5 Remove the setscrews whic h retain the top plate

and fit the three long screws of the kit. Tighten evenly

the screws against the end of the crankshaft to pull

out the seal. Remove the self-tapping screws when

the seal is withdrawn.

To fit

1 Ensure that the crankshaft, the flywheel housing

and the oil seal are clean. Use the kit of the remover/

replacer, 21825 810, to fit the new oil seal at the rear

end of the crankshaft as follows:

Perkins Engines Company Limited

81

This document has been printed from SPI². Not for Resale