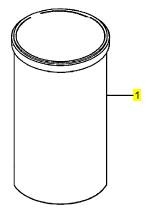

Perkins3012柴油發動機威爾遜P850E柴油發電機配件CV72010缸套

詳細描述

項目 零配件號碼 最近的部分號碼 描述

1 CV72010 12 CV72010 缸套

1 CV19912 12 CV72010 缸套

(1) CV11401 12 CV11401 缸套

(1) CV11402 12 CV11402 缸套 -特大號

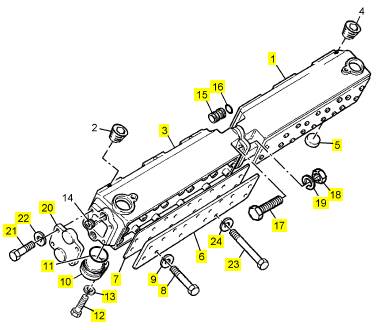

項目 零配件號碼 最近的部分號碼 描述

1 CV12310 2 CV12310 岐管

3 CV12310 2 CV12310 岐管

5 ST43325 2 ST43325 栓塞

6 CV8927 4 CV8927 板

7 CV20227 4 CV20227 密封墊

8 ST44456 16 ST44456 螺拴

9 ST43161 16 2134 A010 彈簧塾圈

10 CV13396 2 CV13396 栓塞

11 ST10935 2 ST10935 封閉砂條

12 ST44441 2 2314 C045 固定螺釘

13 ST43160 2 2134 A008 墊圈

15 CV12311 12 CV12311 線橋

16 ST10890 24 ST10890 封閉砂條

17 ST44458 8 2314 C053 固定螺釘

18 ST44606 6 2318 A209 公制的螺帽

19 ST43161 8 2134 A010 彈簧塾圈

20 CV12560 2 CV12560 帽

21 ST43551 8 ST43551 螺拴

22 ST43161 8 2134 A010 彈簧塾圈

23 ST43574 48 ST43574 螺拴

24 ST43161 48 2134 A010 彈簧塾圈

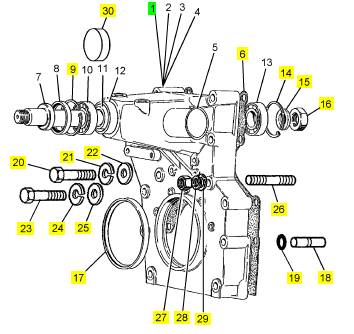

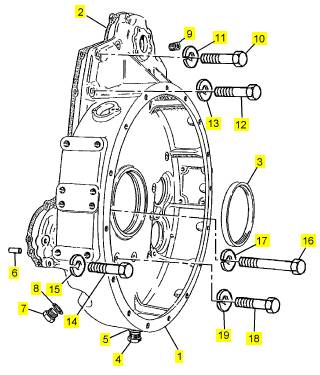

項目 零配件號碼 最近的部分號碼 描述

1 CV9278/1 Z 1 CV9278/1 Z 殼

6 CV20362 1 CV20362 密封墊

9 ST49007 1 ST49007 CIRCLIP

14 ST49007 1 ST49007 CIRCLIP

15 CV5533 1 CV5533 墊圈

16 CV5324 1 CV5324 螺帽

17 CV17402 1 CV17402 密封 -前面端油

18 CV1305 2 CV1305 合釘

19 CV1306 2 CV1306 密封O型圈

20 ST43712 5 ST43712 螺拴

21 ST43164 5 ST43164 墊圈

22 2131 A016 5 2131 A016 墊圈

23 ST43515 9 ST43515 螺拴

24 2134 A008 9 2134 A008 墊圈

25 2131 A008 9 2131 A008 墊圈

26 CV7617 1 CV7617 圖釘

27 2318 A222 1 2318 A222 螺帽

28 ST43164 2 ST43164 墊圈

29 2131 A016 2 2131 A016 墊圈

30 CV14151 2 CV14151 栓塞

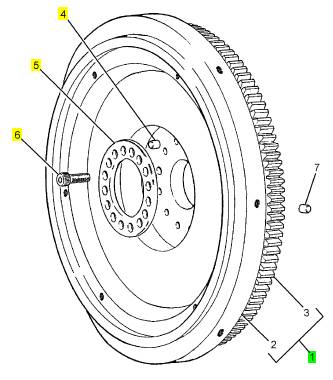

項目 零配件號碼 最近的部分號碼 描述

1 CV14445/1 1 CV14445/1 飛輪組合

4 CV6460 1 CV6460 銷

5 CV2481 1 CV2481 圈

6 ST46709 16 ST46709 CAPSCREW

項目 零配件號碼 最近的部分號碼 描述

1 CV14092 1 飛輪殼

2 CV20222 1 CV20222 密封墊

3 CV17404 1 CV17404 密封 -背面端油

4 ST46079 1 ST46079 栓塞

5 ST49891 1 ST49891 墊圈

6 CV6461 2 CV6461 銷

7 OE25649 1 OE25649 栓塞

8 ST49853 1 ST49853 墊圈

9 ST20704 2 ST20704 栓塞

10 ST43652 1 ST43652 螺拴

11 ST43163 1 ST43163 墊圈

12 ST43603 8 ST43603 公制的螺拴

13 2134 A012 8 2134 A012 墊圈

14 ST43602 2 ST43602 螺拴

15 2134 A012 2 2134 A012 墊圈

16 ST43620 2 ST43620 螺拴

17 2134 A012 2 2134 A012 墊圈

18 ST43605 9 ST43605 螺拴

19 2134 A012 9 2134 A012 墊圈

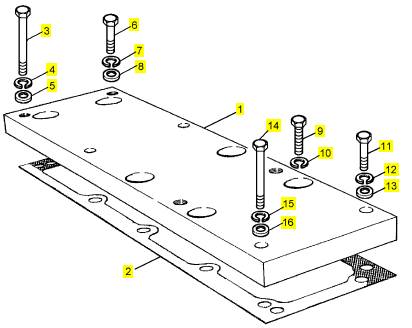

項目 零配件號碼 最近的部分號碼 描述

1 CV1499 1 CV1499 架設板

2 CV19541 1 CV19541 密封墊

3 ST43580 2 ST43580 螺拴

4 2134 A010 2 2134 A010 墊圈

5 2131 A010 2 2131 A010 墊圈

6 ST43552 2 ST43552 螺拴

7 2134 A010 2 2134 A010 墊圈

8 2131 A010 2 2131 A010 墊圈

9 ST44456 6 ST44456 螺拴

10 2134 A010 6 2134 A010 墊圈

11 ST43557 2 ST43557 螺拴

12 2134 A010 2 2134 A010 墊圈

13 2131 A010 2 2131 A010 墊圈

14 ST43583 2 ST43583 螺拴

15 2134 A010 2 2134 A010 墊圈

16 2131 A010 2 2131 A010 墊圈

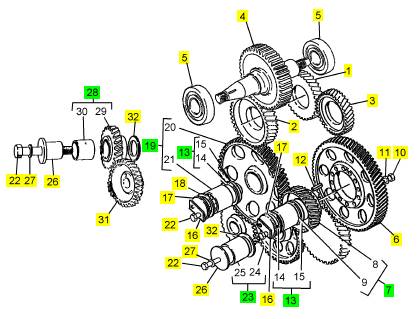

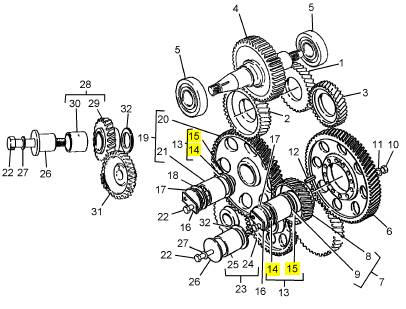

項目 零配件號碼 最近的部分號碼 描述

1 1 凸輪軸傳動機構

2 1 凸輪軸傳動機構

3 1 凸輪軸傳動機構

4 1 高壓油泵傳動機構

5 2 推拔瓦

6 CV70056 1 CV70056 混合傳動機構

6 CV7866 1 CV70056 混合傳動機構

7 CV7868 1 CV7868Z 混合傳動機構

10 CV17071 12 CV17071 固定螺釘

11 ST43056 12 2131 A008 墊圈

12 ST45778 1 ST45778 彈簧銷

13 CV13003 2 CV13003Z 車橋

16 CV8666 2 CV8666 鎖定板

17 CV11604 2 CV11604 推力板

18 CV430 4 CV430 止推片

19 CV1412 1 CV1412Z 惰輪傳動機構

22 CV12174 6 CV12174 螺拴

23 CV1414 1 CV1414Z 惰輪傳動機構

26 CV329 2 CV329 車橋

27 ST43058 2 2131 A012 墊圈

28 CV1415 1 CV1415 惰輪傳動機構

31 1 油泵傳動機構

32 CV1381 2 CV1381 止推片

項目 零配件號碼 最近的部分號碼 描述

14 CV12820 1 CV12820 車橋

15 CV2491 1 CV2491 間隔器

Clean all of the components; use a cleaning fluid

which can be diluted with water and refer to section 10

for relevant information. To remove heavy carbon

deposits from most components: soak them in

solutions of ’Maxan’ or ’Ardrox 667’.

Caution: Do not use the ’Maxan’ or ’Ardrox’

processes on the valve springs or the surface finish

will be damaged.

If cup plugs were removed, before the cylinder head

was cleaned, they must be renewed before the

cy linder head is given a test under pressure. Apply

’Loc tite 575’ to the new cup plugs and insert them into

their correct locations in the cylinder head. Us e the

relevant kit of remov al/replacer tools for the cup

plugs.

Make, locally, enough seals to close all of the

openings for coolant and fit them to the cylinder head.

Connect a pipe from a supply of air to the coolant

galleries. Apply air at a pressure of 207 kN/m² (30 lbf/

in²).

Caution: Do NOT exceed 207 kN/m² (30 lbf/in²) as

damage may be caused.

Put the cylinder head in a tank of water which is at a

temperature of 60°C (140°F) and inspect for bubbles

from around all the cup plugs and injector sleeves.

Renew plugs or sleeves which are not fully sealed.

Remove the seals from the openings for coolant.

Inspect the flame face for s igns of damage. If

necessary, the face may be reconditioned by surface

grinding, in four stages, to a maximum of 0,51 mm

(0.020 in). Information about work done must be

etched on an area of the flame face which is not under

the gasket of the cylinder head.

Caution: When a cylinder head flame face has been

machined, the valve seats must be re-cut to maintain

the correct distance between the valve faces and the

flame face of the cylinder head. See fits and

clearances on page 60.

Perkins Engines Company Limited

45

This document has been printed from SPI². Not for Resale

12

12

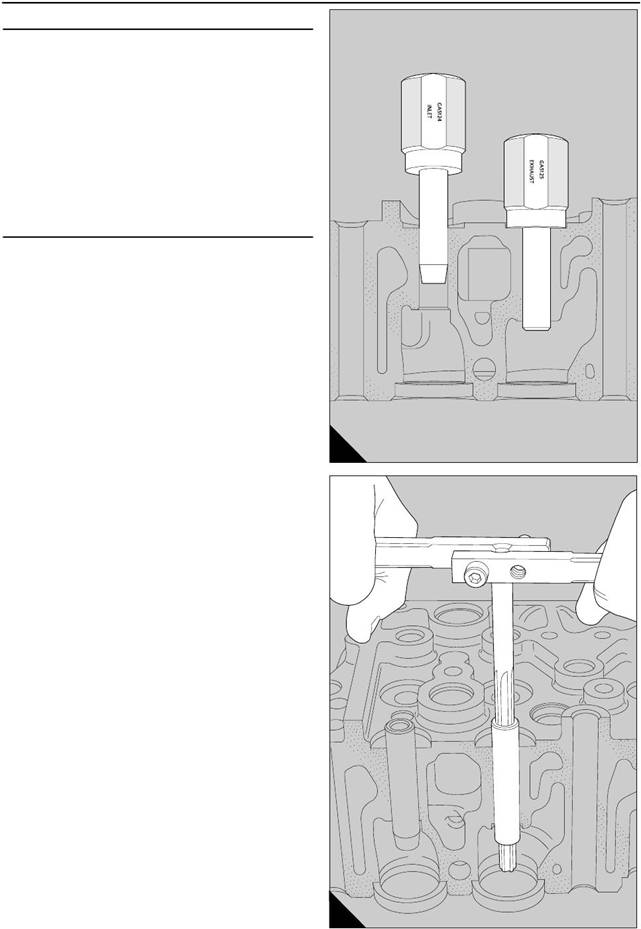

To correct a valve seat

Special tools:

Valve seat tool, 21825 841

Valve seat cutter, 21825 842

12-12

It is recommended that all the valve guides are

inspected, and renewed as necessary, before the

work is begun on the v alve seat inserts. Ensure that

the bores of the guides are within the limits given at

the end of this section.

1 Inspect the inserts for erosion and cracks. If it is

necessary to correct the inserts, lightly lap the faces

of the valve seats and their relevant valves. To correct

the faces of more badly damaged valve seats, use the

valve seat tool, 21825 841, and the cutter, 21825 842,

together with the relevant pilot. To use the tool, fit the

guide (A) and proceed as s hown (B). Ensure that the

cutter is correct for the angle of the v alve seat, which

is giv en on page 60. The surface finish of the valve

seat will be improved if a compressed air supply is

used to remove debris during this operation.

Warning! Ensure that eye protection is used during

the above operation.

Caution: During the correction of a valve seat it is

important to remove only the minimum amount of

material.

2 After the inspection and correction of a valve seat

and the relevant valve, fit the valve into the guide and

check the depth of the head of the valve below the

flame face. If the depth is more than the limits given

on page 60 use a new valve to check again. If the

depth is then within acceptable limits, the new valve

must be fitted to the valve seat when the cy linder

head is assembled.

3 To ensure that the valve is fitted in its correc t

position, the number of the cylinder and the position

of the valve must be etched above the collet groove

on the valve stem. Valves must not be stamped or

A

B

222

223

marked with a centre punch, because crack s may

occur.

If the depth still exceeds the acceptable limits, a new

valve seat insert must be fitted.

46

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

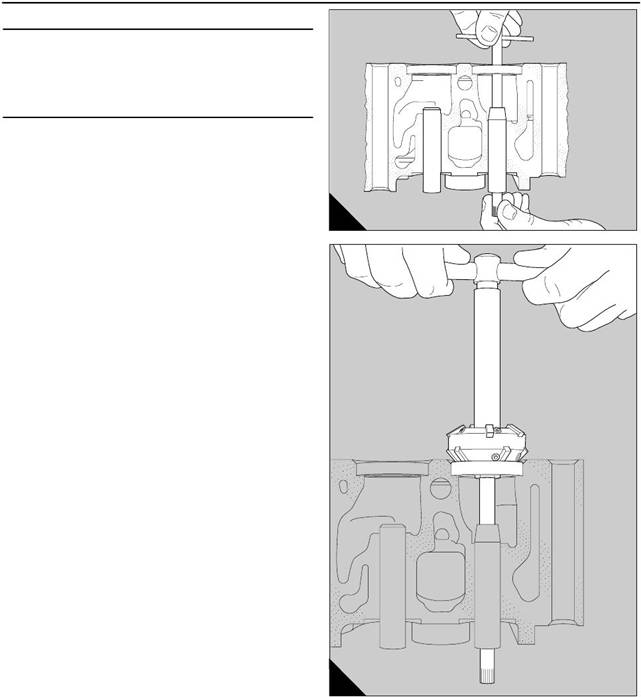

To remove a valve seat insert

Special tools:

Holder, 21825 892

12-13

Cutter for the removal of valve seats, 21825 893

Expendable extractor, 21825 896

Caution: Before a valve seat insert for an exhaust

valve can be removed, the edge of the casting of the

cy linder head, which is rolled over the insert, must be

cut away (A). A special cutter, 21825 893, and holder,

21825 892, are available for this purpose.

1 If the relevant valve guide has not been removed,

and its bore is within the acceptable limits, turn the

cy linder head onto its side and slide the expendable

extractor, 21825 896, into the valve guide, until the

head is in contac t with the valve seat insert.

2 Weld electrically, at two or three equally spaced

positions around the circumferenc e, the expendable

extractor to the valve seat insert. Make the welds no

larger than is necessary in order to prevent damage

to the cylinder head.

3 Use a soft faced hammer on the end of the stem of

the expendable extractor to remove the old valve s eat

insert from its recess (B).

The expendable extractor may be used again if the

welds and the old valve seat insert are removed and

the head is ground lightly to eliminate the protrusions.

A

224

B

225

Perkins Engines Company Limited

47

This document has been printed from SPI². Not for Resale

12

12

|

|

|

|

is given below:

1 Fasten securely the cylinder head on a milling

machine, and use a slot drill of approximately 10 mm

seat insert (A3). The depth of the slots should be 0,50

mm (0.020 in) less than the depth of the valve seat

insert. The minimum depth of the insert is 7,95 mm

(0.313 in). The slots should be apart by

Machine the slot to within 0,5 mm (0.020 in) of the

outside diameter of the insert.

2 Use a flat chisel, at the point which is indicated by

the arrow (A2) and in the direction of the opening in

the insert, to break the insert. Do not damage the

recess during this operation.

3 Remov e the insert and check that the recess is

clean and that there is no damage.

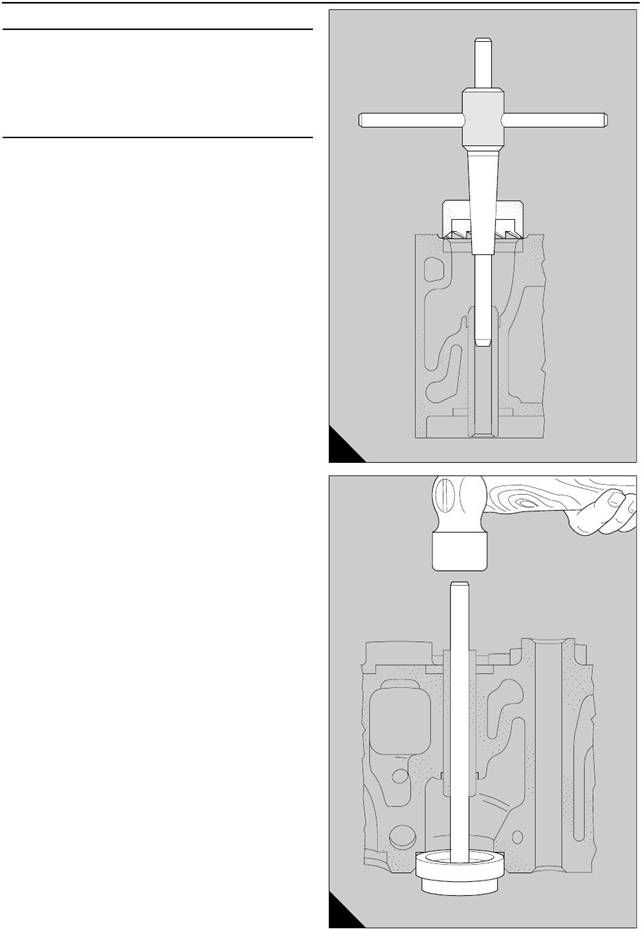

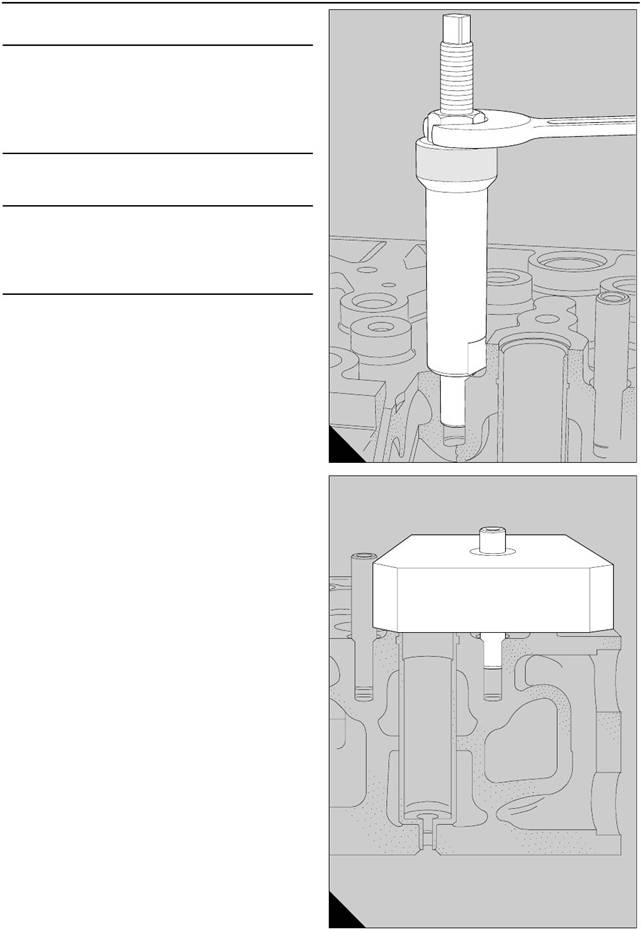

To fit a valve seat insert 12-14

Special tools:

Valve seat tool, 21825 841

Valve seat cutter, 21825 842

Drive handle, 21825 861

Tool to insert valve seat, 21825 867

Holder for rolling tool, 21825 892

Rolling tool, 21825 894

A

34

1 Valve seat inserts are available in two sizes,

oversize and standard. The oversize inserts are 0,05

mm (0.002 in) larger on the outer diameter. If an

oversize insert is to be fitted, ensure that it has the

correct part number: CV 14128 for an inlet seat or OE

47574 for an exhaust seat. Check als o that the wall

of the recess in the cylinder head will maintain the

correct interference fit, as given on page 60.

2 Cool the valve seat insert in liquid nitrogen to -35°C

(-31° F). Use the special tool, 21825 867, (B1) and the

B

226

handle, 21825 861 (B2), to fit the relevant insert into

its rec ess as rapidly as possible.

3 Use a 0,04 mm (0.0015 in) feeler gauge to c heck

that the bottom of the new insert is in full contact with

the bottom of the recess.

If a new v alve seat insert has been fitted for an

exhaust valve, the edge of the casting of the cylinder

head must be rolled over the chamfer which is around

the circumference of the insert. Proceed as follows :

4 Fasten securely the cylinder head on a s uitable drill

machine with the flame face in the upper position and

fit the rolling tool, 21825 894, and holder, 21825 892,

to the machine.

48

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

![]() 12

12

5 Apply clean engine lubricating oil to the rollers, to

the face at the end of the tool and to the c ounterbore

in the cylinder head.

6 Insert the rolling tool in the valve guide and turn

slowly the rolling tool. Apply enough pressure to

spread the material of the cylinder head over the

chamfer of the valve seat insert. Ensure that the face

at the end of the tool is suitably lubricated before the

face at the end of the tool is in contact with the top

face of the insert (A). When this occurs, the cylinder

head is fully rolled over the insert, and the tool can be

removed.

7 Use the valve seat cutter, 21825 842, and the

relevant pilot, to machine to the correct angle, the

seats which have been renewed. Ensure that the

cutter is correct for the angle of the valve seat, which

is given on page 60. Lap the valves to the seats.

Clean thoroughly the area around the valv es and the

seats and use engineer’s blue to check that the fac es

of the valves are in full contact across and around the

faces of the valve seats.

8 Fit the valves in their relevant seats and use a

straight edge and a feeler gauge to check that the

clearances between the heads of the valves and the

flame face are within the limits given on page 60. If a

clearance is excessive, a new valve must be fitted.

The number of the cylinder and the position of the

valve should be etched above the collet groove on the

A

227

valve stem. Valves must not be stamped or marked

with a centre punch, because cracks may occur.

To inspect the valve guides 12-15

Check the clearance of each valve stem in its guide.

This must be within the limits given on page 59. If the

clearance is excessive, use a new valve to check

again. If the c learance is still excessive, a new valve

guide must be fitted.

Perkins Engines Company Limited

49

This document has been printed from SPI². Not for Resale

12

12

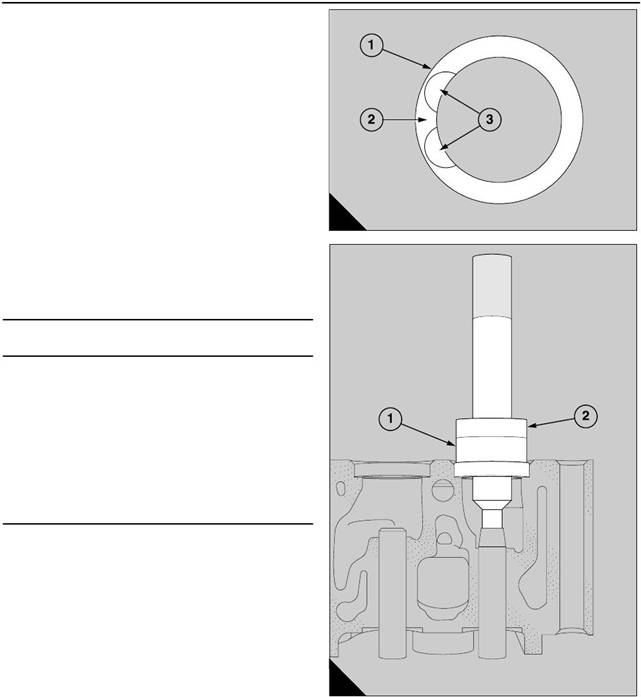

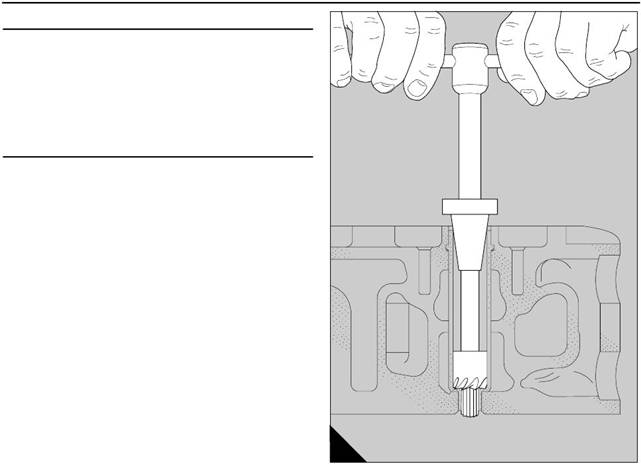

To renew a valve guide

Special tools:

Reamer for exhaust valve guides, 21825 755

Reamer for inlet valve guides, 21825 756

Valve seat tool, 21825 841

Valve seat cutter, 21825 842

Remover for inlet valv e guides, 21825 885

12-16

Remover for exhaust valve guides, 21825 886

Replacer for inlet valve guides, 21825 887

Replacer for ex haust valv e guides, 21825 888

Use the extractors: 21825 885 (inlet valves) or 21825

886 (exhaust valves), and the replacer tools 21825

887 (inlet valves) or 21825 888 (exhaust valves),

together with a suitable press.

1 Use the relevant extractors to press out the valve

guides that need to be renewed. Check the bores in

the cylinder head for wear or damage. See SRS 135

for instructions to correct worn bores.

2 Apply clean lubricating oil to the new guide before

it is inserted in the top end of the bore.

Caution: The guides for the inlet valves must be

inserted with the tapered end downward. The guides

for the exhaust valves must be inserted with the

internal chamfer, which is at one end of the bore, at

the top.

3 Fit the relevant replacer tool onto the guide and

press the guide in until the replacer tool is in c ontact

with the cylinder head (A). This will give the correct

protrusions of 12,8 mm (0.50 in) for the guides of the

inlet valves and 17,85 mm (0.70 in) for the guides of

the exhaust valves.

Caution: If liquid air is available, it may be help if the

new valve guide is cooled immediately before it is

fitted.

4 Use the correct reamer to ream the new valve guide

(B) and check the bore with the relevant plug gauge.

Use the reamer 21825 756 for inlet valve guides and

21825 755 for exhaust valve guides.

If new valve guides have been fitted, the relevant

valve seat insert must be corrected. Use the special

tool, 21825 842, to ensure concentricity.

A

230

B

231

50

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale

12

12

|

12-17

Inspect the bridge pieces and the adjustment screws

for wear. Use a new guide as a gauge to c heck the

bores in the bridge pieces. Similarly, use a new

bridge piece to check the guides. Renew

components which have excessive wear.

|

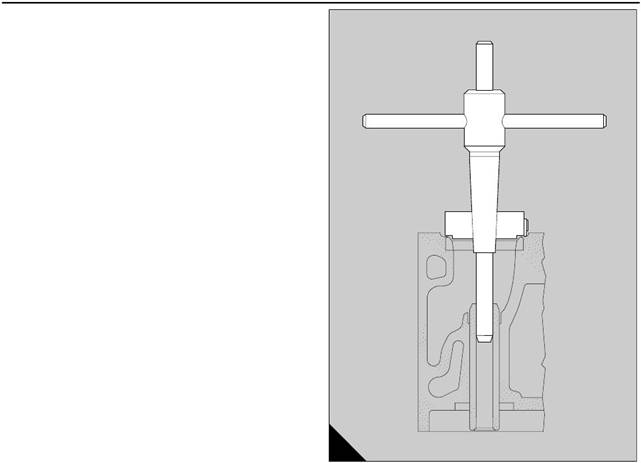

Special tools:

Extractor for valve bridge guides, 21825 889

12-18

Depth plate for valve bridge guides, 21825 890

Use the extractor, 21825 889, to withdraw a worn

guide from its bore in the cylinder head (A). Clean

thoroughly the bore.

Apply ’Loctite 648’ to the area of the new guide which

is an interference fit in the cylinder head and use a

press to insert the guide into the c ylinder head. To

obtain the correct protrusion, fit the depth plate,

21825 890, ov er the guide and press the guide into its

bore until the top face is aligned precisely with the top

face of the depth plate (B).

A

232

B

233

Perkins Engines Company Limited

51

This document has been printed from SPI². Not for Resale

12

12

To recondition a fuel injector sleeve

Special tools:

12-19

Tool holder for face cutter and reamer, 21825 765

Face cutter, 21825 767

Reamer, 21825 768

Service kit for fuel injector sleeves, 21825 915

Caution:

The fuel injector sleeves may be renewed

without the removal of the cylinder head from the

engine. In this situation, the coolant must be drained

until the level is below the cylinder head and the

piston, which is below the faulty fuel injector sleeve,

must be moved to BDC.

1 Use the integral face cutter and reamer to remove

deposits of carbon and to correct the face of the seat,

or the bore at the smaller internal diameter of the

injector sleeve (A). If the work is done without the

removal of the cylinder head from the engine, the

cutter and the reamer must be given a full application

of grease to retain the particles of the carbon and the

debris.

Caution: When the face cutter is used, remove only

the minimum material that is necessary to correct the

seat. The maximum permissible depth of the seat

from the top face of the cylinder head is 104,25 mm

A

237

(4.104 in).

52

Perkins Engines Company Limited

This document has been printed from SPI². Not for Resale