Perkins3012柴油發動機威爾遜P850E柴油發電機配件提升泵

詳細描述

項目 零配件號碼 最近的部分號碼 描述

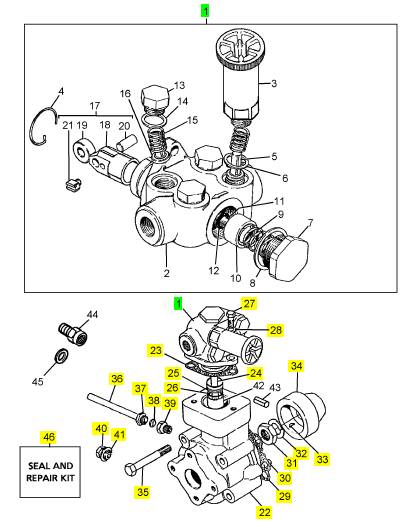

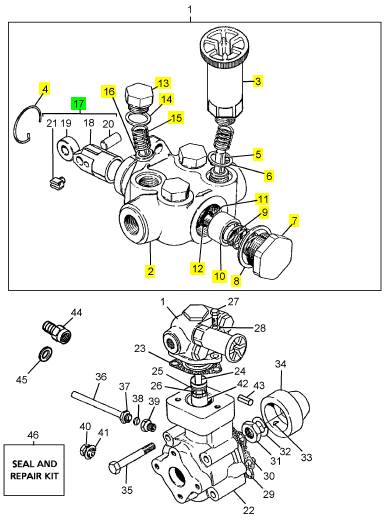

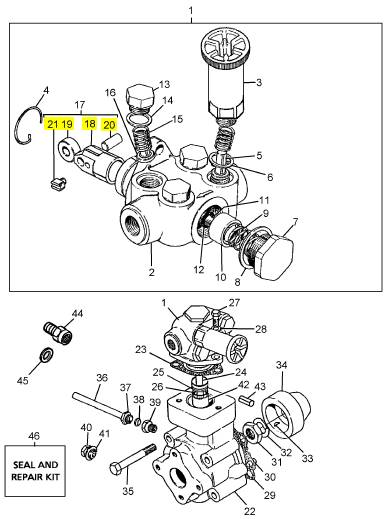

1 OD17308 1 OD17308 提升泵

(1) OD17308R 1 OD17308R 提升泵 -交換

22 CV8843 1 CV8843 殼

23 OD19655 1 OD19655 密封墊 - 提升泵

24 CV7853 1 CV7853 PUSHROD

25 CV7854 1 CV7854 轉向裝置

26 ST10545 1 ST10545I 封閉砂條

27 ST44424 3 ST44424 固定螺釘

28 2131 A012 3 2131 A012 墊圈

29 CV20220 1 CV20220 密封墊 - 提升泵

30 ST45778 2 ST45778 彈簧銷

31 ST44630 1 ST44630 螺帽

32 ST43164 1 ST43164 墊圈

33 ST17031 1 ST17031 半圓鍵

34 CV5455 1 CV5455 電腦輔助制造

35 ST43511 4 ST43511 螺拴

36 CV18437 1 CV18437 燃料管

37 ST46260 1 ST46260 異徑管接合器

38 ST46004 2 ST46004 套筒

39 ST46029 2 ST46029 螺帽

40 ST49458 1 ST49458 承接器

41 ST49891 1 ST49891 墊圈

46 KRP1209 1 KRP1209 修補裝備 - 提升泵

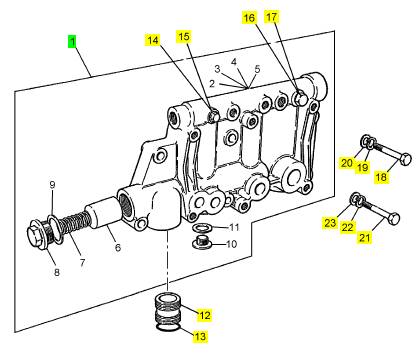

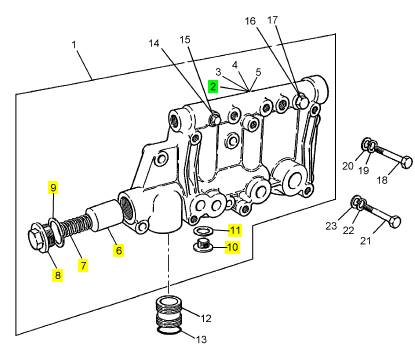

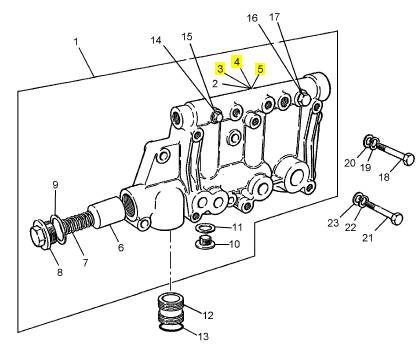

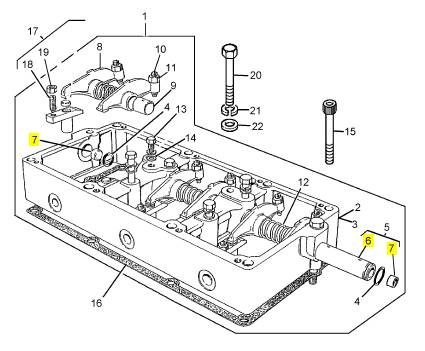

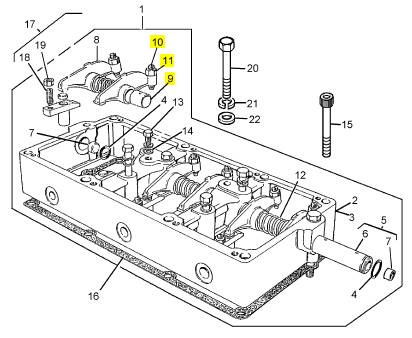

項目 零配件號碼 最近的部分號碼 描述

2 OD17701 1 OD17701 殼

3 OD20513 1 OD20513 汽酒共騰泵

4 OD17712 1 OD17712 扣環

5 OD17717 1 OD17717 閥

6 OD17715 1 OD17715 密封墊

7 OD17706 1 OD17706 栓塞

8 OD17707 1 OD17707 密封墊

9 OD17705 1 OD17705 彈簧

10 OD17703 1 OD17703 柱塞

11 OD17704 1 OD17704 旋刮板心橋

12 OD17702 1 OD17702 密封O型圈

13 OD17714 3 OD17714 栓塞

14 OD17715 3 OD17715 密封墊

15 OD17713 4 OD17713 彈簧

16 OD17717 3 OD17717 閥

17 OD17753 1 OD17753 挺桿

項目 零配件號碼 最近的部分號碼 描述

18 OD17708 1 OD17708 挺桿

19 OD17709 1 OD17709 位子

20 OD17710 1 OD17710 銷

21 OD17711 2 OD17711 臺

項目 零配件號碼 最近的部分號碼 描述

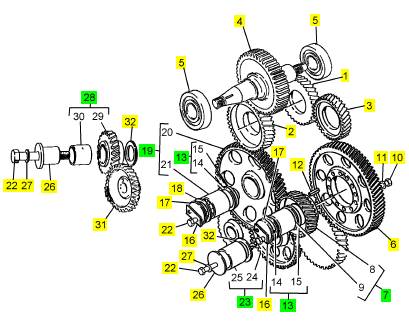

1 1 凸輪軸傳動機構

2 1 凸輪軸傳動機構

3 1 凸輪軸傳動機構

4 1 高壓油泵傳動機構

5 2 推拔瓦

6 CV70056 1 CV70056 混合傳動機構

6 CV7866 1 CV70056 混合傳動機構

7 CV7868 1 CV7868Z 混合傳動機構

10 CV17071 12 CV17071 固定螺釘

11 ST43056 12 2131 A008 墊圈

12 ST45778 1 ST45778 彈簧銷

13 CV13003 2 CV13003Z 車橋

16 CV8666 2 CV8666 鎖定板

17 CV11604 2 CV11604 推力板

18 CV430 4 CV430 止推片

19 CV1412 1 CV1412Z 惰輪傳動機構

22 CV12174 6 CV12174 螺拴

23 CV1414 1 CV1414Z 惰輪傳動機構

26 CV329 2 CV329 車橋

27 ST43058 2 2131 A012 墊圈

28 CV1415 1 CV1415 惰輪傳動機構

31 1 油泵傳動機構

32 CV1381 2 CV1381 止推片

項目 零配件號碼 最近的部分號碼 描述

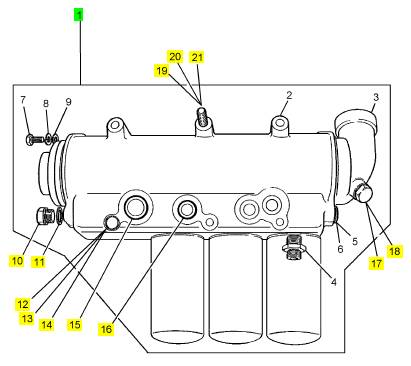

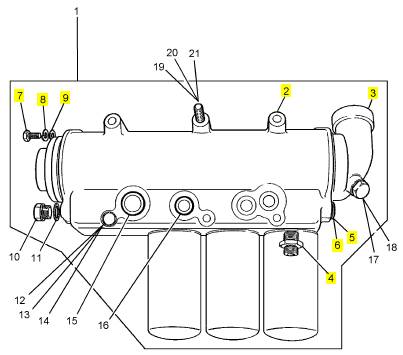

1 CV13140Z 1 CV13140Z 機油冷卻器

10 ST46078 1 ST46078I 栓塞

11 ST49853 1 ST49853 墊圈

12 ST43622 3 ST43622 螺拴

13 2134 A012 3 2134 A012 墊圈

14 2131 A012 3 2131 A012 墊圈

15 ST10616 1 ST10616 密封O型圈

16 ST10609 3 ST10609 密封O型圈

17 ST46077 1 ST46077 栓塞

18 ST49852 1 ST49852 墊圈

19 ST43620 3 ST43620 螺拴

20 2134 A012 3 2134 A012 墊圈

21 2131 A012 3 2131 A012 墊圈

項目 零配件號碼 最近的部分號碼 描述

2 CV13139 1 CV13139 套

3 CV5620 1 CV5620 TUBESTACK

4 CV13136 3 CV13136 承接器

5 ST20134 1 ST20134 栓塞

6 ST49206 1 ST49206 墊圈

7 ST44424 2 ST44424 固定螺釘

8 2131 A012 2 2131 A012 墊圈

9 2131 A006 2 2131 A006 墊圈

項目 零配件號碼 最近的部分號碼 描述

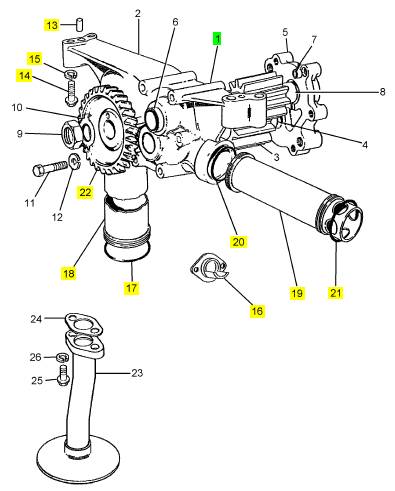

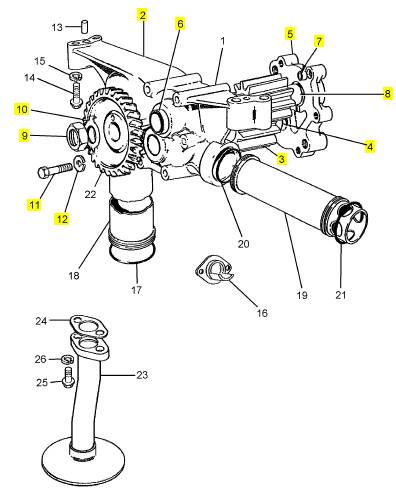

1 CV11804 1 CV11804 油泵

(1) CV11804R 1 CV11804R 油泵 -交換

13 OE4421 2 OE4421 銷

14 ST43557 4 ST43557 螺拴

15 2134 A010 4 2134 A010 墊圈

16 CV13176 1 CV13176 栓塞

17 ST10619 2 ST10619 密封O型圈

18 CV12722 1 CV12722 油管

19 CV12723 1 CV12723 線橋

20 ST10615 1 ST10615 密封O型圈

21 ST10616 1 ST10616 密封O型圈

22 CV1274 1 CV1274 油泵傳動機構

項目 零配件號碼 最近的部分號碼 描述

2 CV11802 1 CV11802 套

3 CV2279 1 CV2279 油泵傳動機構

4 CV5340 1 CV5340 橋

5 CV11803 1 CV11803 蓋

6 CV358 2 CV358 襯套

7 CV5671 1 CV5671 合釘

8 CV5339 1 CV5339 橋

9 ST44632 1 ST44632 鎖緊螺母

10 CV334 1 CV334 定位鍵墊圈

11 ST43518 6 ST43518 螺拴

12 2134 A008 6 2134 A008 墊圈

項目 零配件號碼 最近的部分號碼 描述

1 CV7755/1 Z 1 CV7755/1 Z 閥

12 CV5122 2 CV5122 線橋

13 ST10615 8 ST10615 密封O型圈

14 ST46077 1 ST46077 栓塞

15 ST49852 1 ST49852 墊圈

16 ST46078 1 ST46078I 栓塞

17 ST49853 1 ST49853 墊圈

18 ST43655 3 ST43655 螺拴

19 ST43163 3 ST43163 墊圈

20 ST43059 3 ST43059 墊圈

21 ST43657 3 ST43657 螺拴

22 ST43163 3 ST43163 墊圈

23 ST43059 3 ST43059 墊圈

項目 零配件號碼 最近的部分號碼 描述

2 1 放泄閥

6 CV5121 1 CV5121 柱塞

7 CV1558 1 CV1558 彈簧

8 CV7719 1 CV7719 帽

9 ST49859 1 ST49859 墊圈

10 ST20106 2 ST20106 栓塞

11 ST49856 2 ST49856 墊圈

Item Parts No. Qty. Latest Part No. Description Cut Out Cut In Comment

3 ST11412 3 ST11412 INSERT

4 ST11421 1 ST11421 INSERT

5 ST47474 6 ST47474 INSERT

項目 零配件號碼 最近的部分號碼 描述

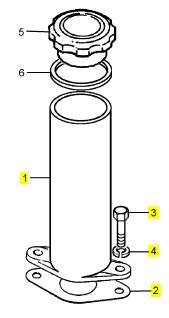

1 CV12724 1 CV12724 油填隙料

2 OE52128 1 OE52128 密封墊

3 ST43552 2 ST43552 螺拴

4 2134 A010 2 2134 A010 墊圈

項目 零配件號碼 最近的部分號碼 描述

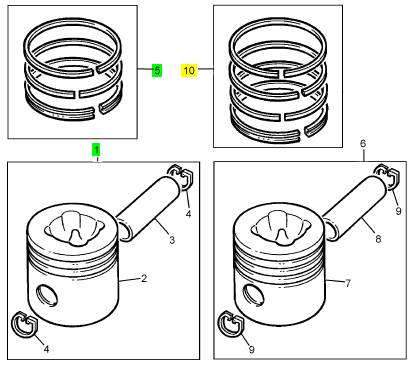

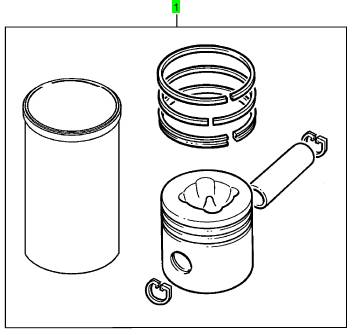

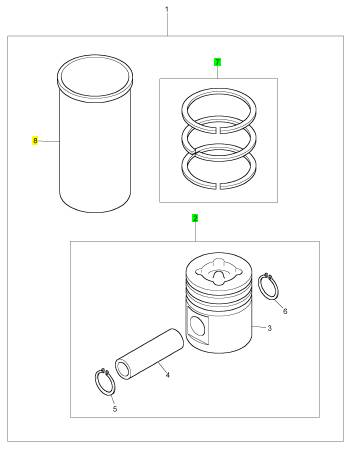

1 CV19327/1 12 活塞裝備

5 CVK564 12 CVK564 活塞環裝備

10 CVK502 12 CVK502 活塞環裝備

項目 零配件號碼 最近的部分號碼 描述

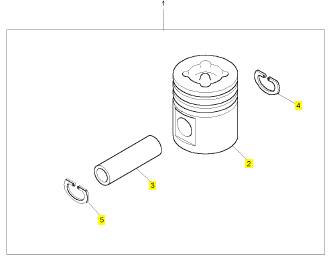

2 1 活塞

3 1 橋頭銷

4 CV19330 2 CV19330 CIRCLIP

項目 零配件號碼 最近的部分號碼 描述

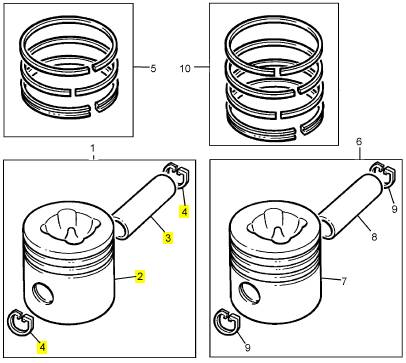

1 CV285 24 CV285 PUSHROD

2 CV70122 24 CV70122 挺桿

2 CV65451 24 CV70122 挺桿

項目 零配件號碼 最近的部分號碼 描述

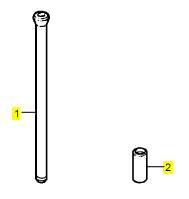

1 CV21206 1 CV24620 散熱器

2 CV17913 1 CV17913 守衛

3 CV17912 1 CV17912 守衛

4 2314 C044 12 2314 C044 固定螺釘

5 0920053 12 0920053 墊圈

6 CV69938 1 CH12541 開關

6 OD20769 1 CH12541 冷卻器水平開關

7 ST15902 12 ST15902 墊圈

項目 零配件號碼 最近的部分號碼 描述

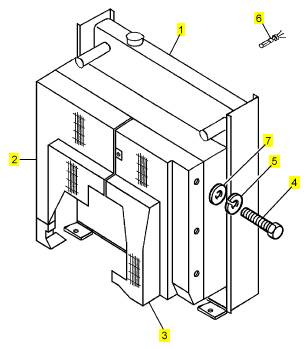

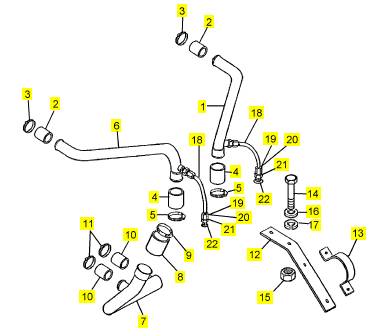

1 CV17595 1 CV17595 水管

2 ST91216 2 ST91216 水管

3 ST46409 4 ST46409 夾

4 ST91232 2 ST91232 水管

5 ST46411 4 ST46411 夾

6 CV17596 1 CV17596 水管

7 CV17103 1 CV17103 水管

8 ST91247 1 ST91247 水管

9 ST46412 2 ST46412 夾

10 ST91216 2 ST91216 水管

11 ST46409 4 ST46409 夾

12 CV17109 1 CV17109 托架

13 CV17108 1 CV17108 夾

14 2314 C044 4 2314 C044 固定螺釘

15 2318 A208 4 2318 A208 螺帽

16 2134 A008 4 2134 A008 墊圈

17 2131 A008 4 2131 A008 墊圈

18 CV17910 2 CV17910 水管

19 ST46005 4 ST46005 套筒

20 ST46030 4 ST46030 螺帽

21 ST49439 4 ST49439 承接器

22 ST49852 4 ST49852 墊圈

項目 零配件號碼 最近的部分號碼 描述

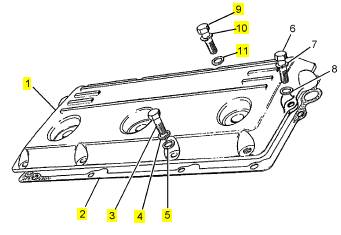

1 CV2170 4 CV2170 汽缸蓋蓋

2 CV20230 4 CV20230 密封墊 -CYL。 冒口蓋

3 2314 C045 16 2314 C045 固定螺釘

4 2134 A008 16 2134 A008 墊圈

5 2131 A008 16 2131 A008 墊圈

9 ST43504 16 ST43504 螺拴

10 2134 A008 16 2134 A008 墊圈

11 2131 A008 16 2131 A008 墊圈

項目 零配件號碼 最近的部分號碼 描述

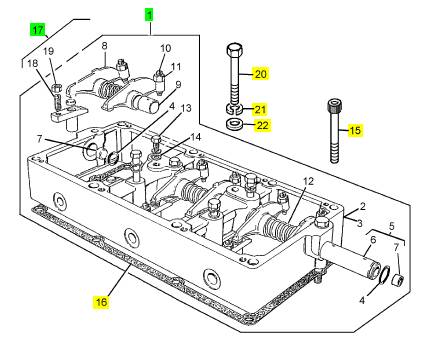

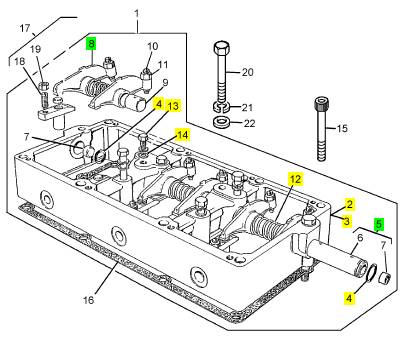

1 CV18695 4 CV18695 搖桿砂箱組合

15 ST46614 32 ST46614 CAPSCREW

16 CV14055 4 CV20376 密封墊

17 OE52035 24 CV24523 結橋

20 ST43563 32 ST43563 螺拴

21 ST43161 32 2134 A010 彈簧塾圈

22 ST43057 32 2131 A010 墊圈

項目 零配件號碼 最近的部分號碼 描述

1 搖桿砂箱

ST43160 1 2134 A008 墊圈

2 CV2255 8 CV2255 墊圈

3 ST47452 8 ST47452 氣門座圈

4 CV1619 2 CV1619 密封O型圈

5 CV8160/2 1 CV8160/2 Z 搖桿橋組合

8 CV1913 6 CV1913 搖臂組合

12 OE43641 3 OE43641 搖桿橋彈簧

13 CV593 1 CV593 螺旋

14 ST43056 1 2131 A008 墊圈

項目 零配件號碼 最近的部分號碼 描述

6 1 搖桿橋

7 ST43305 2 ST43305 栓塞

項目 零配件號碼 最近的部分號碼 描述

9 OE28549 1 OE28549 襯套

10 OE41699 1 OE41699 螺旋

11 OE42293 1 OE42293 鎖緊螺母

項目 零配件號碼 最近的部分號碼 描述

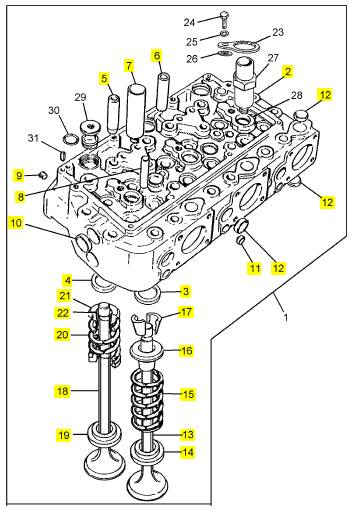

1 CV14447 4 CV17509Z 汽缸蓋組合

(1) CV14447R 4 CV14447R 汽缸蓋裝備 -EXCH

項目 零配件號碼 最近的部分號碼 描述

2 1 汽缸蓋

3 CV20814 6 CV20814 閥座氣門座圈

3 CV21069 1 CV21069 氣門座圈

4 CV20815 6 CV20815 閥座氣門座圈

4 CV21070 1 CV21070 氣門座圈

5 OE47572 6 OE47572 氣門導管

6 OE47573 6 OE47573 氣門導管

7 CV14134 3 CV14134 套筒

8 OE43636 6 OE43636 氣門導管

9 ST20701 1 ST20701 栓塞

10 ST43322 9 ST43322 栓塞

11 ST43309 3 ST43309 栓塞

12 ST43317 9 ST43317 栓塞

13 CV17435 6 CV21058 進氣門

14 OE43638 6 OE43638 位子

15 CV11403 6 CV11403 閥彈簧

16 OE43262 6 OE43262 位子

17 OE42571 12 OE42571 閥筒夾

18 CV17434 6 排氣閥

19 OE43638 6 OE43638 位子

20 CV11403 6 CV11403 閥彈簧

21 CV18761 6 CV18761 回轉的人

22 OE42570 12 OE42570 閥筒夾

項目 零配件號碼 最近的部分號碼 描述

1 CVK523/3 1 CVK523/3 活塞及缸套裝備

項目 零配件號碼 最近的部分號碼 描述

2 CV66887/1 1 CV66887/1 活塞裝備

7 CVK564 1 CVK564 活塞環裝備

8 CV72010 1 CV72010 缸套

8 CV19912 1 CV72010 缸套

(8) CV11401 1 CV11401 缸套

(8) CV11402 1 CV11402 缸套 -特大號

項目 零配件號碼 最近的部分號碼 描述

2 1 活塞

3 1 橋頭銷

4 CV19330 1 CV19330 CIRCLIP

5 CV19330 1 CV19330 CIRCLIP

項目 零配件號碼 最近的部分號碼 描述

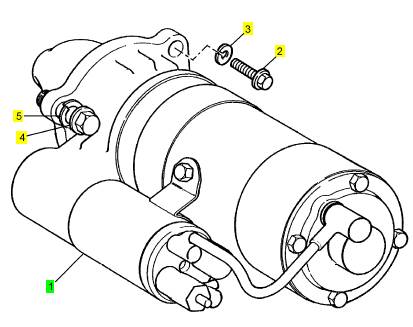

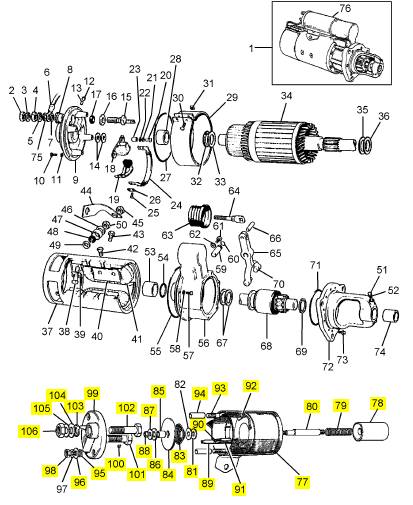

1 CV5296 1 CV65430 啟動馬達

(1) CV5296R 1 CV65430R 啟動馬達 -交換

2 ST44500 2 ST44500 固定螺釘

3 ST43164 2 ST43164 墊圈

4 ST44500 1 ST44500 固定螺釘

5 ST43164 1 ST43164 墊圈

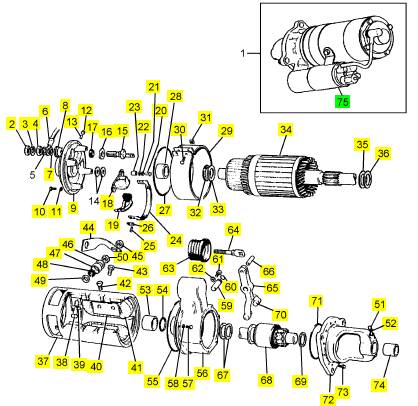

Item Parts No. Qty. Latest Part No. Description Cut Out Cut In Comment

2 OD17688 1 OD17688 LOCKNUT

3 OD15391 1 OD15391 WASHER

4 OD15390 1 OD15390 NUT

5 OD15400 1 OD15400 WASHER

6 CV3022 1 CV3022 LEAD

7 OD19782 1 OD19782 WASHER

8 OD15396 2 OD15396 BUSH

9 OD17266 1 OD17266 HOUSING

10 &am, p;nb, sp; OD15401 4 OD15401 SETSCREW

11 OD15402 4 OD15402 WASHER

12 OD15392 1 OD15392 PLUG

13 OD16762 1 OD16762 WICK

14 OD15404 12 OD15404 WASHER

15 OD17267 1 OD17267 CONNECTION

16 OD15400 1 OD15400 WASHER

17 OD15397 1 OD15397 CIRCLIP

18 OD17268 4 OD17268 HOLDER

19 OD15415 8 OD15415 BRUSH

20 OD15408 4 OD15408 SCREW

21 OD15407 4 OD15407 WASHER

22 OD15406 4 OD15406 WASHER

23 OD15405 4 OD15405 BUSH

24 CV4828 1 CV4828 CONNECTION

25 OD15412 8 OD15412 SCREW

26 OD15411 4 OD15411 PLATE

27 OD15417 1 OD15417I SEAL - O RING

28 OD15399 1 OD15399 BUSH

29 OD17269 1 OD17269 BAND

30 OD17270 2 OD17270 SCREW

31 OD15419 2 OD15419 NUT

32 OD15410 1 OD15410 WASHER

33 OD15409 1 OD15409 WASHER

34 OD21480 1 OD21480 ARMATURE

35 OD15423 1 OD15423 WASHER

36 OD15424 1 OD21474 WASHER

37 CV3024 1 CV3024 CASE ASSEMBLY

38 CV3027 1 CV3027 SCREW

39 OD20701 1 OD20701 INSULATOR

40 CV3026 4 CV3026 MAGNETIC PLATE

41 CV3025 1 CV3025 COIL

42 OD16748 8 OD16748 SCREW

43 OD15422 2 OD15422 SCREW

44 CV3021 1 CV3021 CONNECTION

45 OD17688 3 OD17688 LOCKNUT

46 CV3030 1 CV3030 WASHER

47 OD20703 1 OD20703 INSULATOR

48 OD15397 1 OD15397 CIRCLIP

49 OD20702 1 OD20702 INSULATOR

50 OD15390 1 OD15390 NUT

51 OD15392 1 OD15392 PLUG

52 OD16762 1 OD16762 WICK

53 OD19783 1 OD19783I SLEEVE

54 OD16755 1 OD16755 SEAL - O RING

55 OD15417 1 OD15417I SEAL - O RING

56 OD17275 1 OD17275 HOUSING

57 OD16754 5 OD16754 SCREW

58 OD15402 5 OD15402 WASHER

59 OD16753 1 Check History LEVER

60 OD16752 1 OD16752 SEAL - O RING

61 OD16751 1 OD16751 SCREW

62 OD17276 1 OD17276 WASHER

63 OD16765 1 OD16765 BOOT

64 OD16756 1 OD16756 SCREW

65 CV3031 1 CV3031 LEVER

66 OD16747 1 OD16747I ROLL PIN

67 OD15424 2 OD21474 WASHER

68 OD16758 1 Y97/00032 DRIVE

69 CV4838 1 CV4838 THRUST WASHER

70 CV3032 2 CV3032 ARM

71 OD16759 1 OD16759 SEAL - O RING

72 OD20704 1 OD20704 HOUSING

73 OD16761 6 OD16761 SCREW

74 OD15399 1 OD15399 BUSH

75 OD16764 1 OD16764 SOLENOID

Item Parts No. Qty. Latest Part No. Description Cut Out Cut In Comment

77 OD17291 1 OD17291 MAGNET

78 OD17297 1 OD16764 PLUNGER

79 OD17282 1 OD17282 SPRING

80 OD18509 1 OD18509 SHAFT

81 OD17252 3 OD17252 WASHER

83 OD17283 1 OD17283 SPRING

84 OD17284 1 OD17284 CONTACT

85 OD17285 1 OD17285 BUSH

86 OD17287 1 OD17287 INSULATOR

87 OD17185 1 OD17185 WASHER

88 OD17288 1 OD17288 NUT

89 1 TERMINAL

90 1 TERMINAL

91 OD17286 1 OD17286 GUARD

92 2 TERMINAL

93 2 SCREW

94 OD17292 2 OD17292 INSULATOR

95 OD17279 2 OD17279 RING

96 OD17252 1 OD17252 WASHER

98 OD17196 2 OD17196 NUT

99 OD17245 1 OD17245 BASE

100 OD17231 1 OD17231 SCREW

101 OD17298 1 OD17298 SCREW

102 OD17299 1 OD17299 SCREW

103 OE52575 4 OE52575 SEAL - O RING

104 OD17280 2 OD17280 WASHER

105 OD15391 2 OD15391 WASHER

106 OD15390 2 OD15390 NUT

項目 零配件號碼 最近的部分號碼 描述

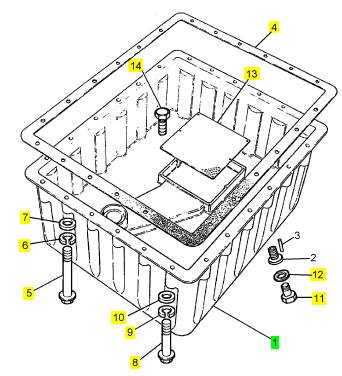

1 CV2852/1 1 CV12350 油底殼

4 CV20214 1 CV20214I 密封墊 -油底殼

5 ST43586 4 ST43586 螺拴

6 2134 A010 4 2134 A010 墊圈

7 2131 A010 4 2131 A010 墊圈

8 ST43561 20 ST43561 螺拴

9 2134 A010 20 2134 A010 墊圈

10 2131 A010 20 2131 A010 墊圈

11 CV985 1 CV985 栓塞

12 ST49206 1 ST49206 墊圈

13 CV2874 1 CV2874 過濾器

14 CV1275 7 CV1275 自己的出鐵螺旋

項目 零配件號碼 最近的部分號碼 描述

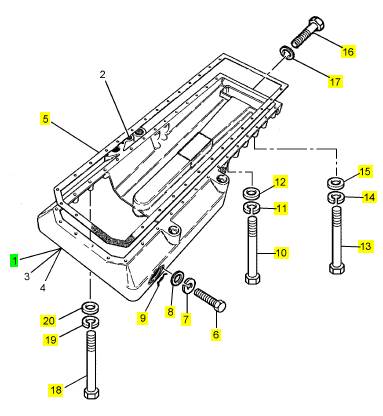

1 CV13339 1 CV13339 油底殼承接器

5 CV20213 1 CV20213 密封墊 -油底殼

6 ST43502 2 ST43502 螺拴

7 2134 A008 2 2134 A008 墊圈

8 2131 A008 2 2131 A008 墊圈

9 ST10619 1 ST10619 密封O型圈

10 ST46633 2 ST46633 CAPSCREW

11 2134 A010 2 2134 A010 墊圈

12 2131 A010 2 2131 A010 墊圈

13 ST43561 12 ST43561 螺拴

14 2134 A010 12 2134 A010 墊圈

15 2131 A010 12 2131 A010 墊圈

16 ST46633 5 ST46633 CAPSCREW

17 2134 A010 5 2134 A010 墊圈

18 ST43558 14 ST43558I 螺拴

19 2134 A010 14 2134 A010 墊圈

20 2131 A010 14 2131 A010 墊圈

|

or an engine which has been in storage

Prepare to start the engine as given in paragraphs 1

to 13 on page 11.

If an engine has been in storage for a period of more

than one month, add clean lubricating oil to the fuel

injection pump and to the turbochargers. If the engine

has been in storage for less than one month, but the

fuel injection pump has been removed and fitted, add

lubricating oil to the fuel injection pump. The

procedure is described on page 11, paragraphs 10

and 11. Use clean engine oil of the same grade and

specification as that already in the system.

Start procedure

Ensure that the stop control is in the STOP position

and that the speed control lever is in the IDLE

position. Press the start button for 10 seconds and

then release it for 10 seconds, then press it for 20

seconds and release it for 20 seconds. Oil pressure

MUST be indicated on the gauge. Move the stop

control lever to the RUN position and proceed as for

a normal start.

12

This document has been printed from SPI². Not for Resale

Normal start procedures

Precautions

3

|

1 Check that the level of coolant is just at the bottom

of the filler extens ion in the radiator. Fill, if necessary,

to the required level with the approved coolant

mixture. If there is a large loss of coolant find the

reason.

2 Check the engine oil level. With the engine

stopped the oil level must be at the H mark on the

dipstic k. If nec essary, add oil of the s ame grade and

specification as that already in the system. Do NOT

add more oil than is necessary.

3 Ensure that the fuel tank is full.

4 Check the air restriction indicator.

Caution: If a fuel injection pump or turbocharger has

been removed from an engine, it must be primed with

clean engine oil of the correct grade before the engine

is first started. See page 11, paragraphs 10 and 11.

Variable speed engines

Perform the daily service checks then proceed as

follows:

Turn on the fuel supply.

Move the stop control to the RUN position.

Move the speed control lever to the maximum speed

position.

Press the start button and release it when the engine

starts.

Move the speed control lever to the idle position.

Constant speed engines

Perform daily service checks then proceed as follows:

Turn on the fuel supply.

Move the stop control to the RUN position.

Press the start button and release it when the engine

starts.

temperatures

An excess fuel device, within the fuel injec tion pump,

works as a starting aid when ambient temperatures

are below 0°C.

Before the engine is started, push fully in, the control

rod of the excess fuel device. Press the start button

and release it when the engine s tarts. The control rod

returns automatically to its original position when the

engine starts.

Caution: The excess fuel device must not be used at

the same time as other c old starting aids as the extra

fuel will make the engine more difficult to start.

The precautions that follow will help to ensure a long

and fault-free life for the engine:

Variable speed engines

1 Do not operate the engine at high speeds and loads

until the coolant has reached a minimum temperature

of 78°C.

2 Do not allow the engine to run at idle speed for

prolonged periods.

3 Do not exceed the maximum no load speed.

4 Never allow an engine to continue to run if the oil

pressure is below 170 kN/m² (25 lbf/in²) at rated

speed.

5 Fill the fuel tank(s) at the end of each day to prevent

condensation.

Constant speed engines

1 Do not operate the engine with a full load until the

coolant has reached a minimum temperature of 78° C.

2 Do not allow the engine to run with no load for

prolonged periods.

3 Ensure that the fuel tank(s) are full to prevent

condensation.

How to st op the engine

Variable speed engines

1 Put the gear lever into the NEUTRAL position.

2 Operate the engine at approximately 800 rev/min

for 3 minutes to allow the turbochargers to reduce

speed and temperature.

3 Mov e the s top control to the STOP position.

Constant speed engines

1 Operate the engine for 3 minutes at idle speed with

no load to allow the turbochargers to reduce speed

and temperature.

2 Mov e the switches for the engine protection

devices to the OFF position.

3 Mov e the s top control to the STOP position.

4 Turn off the fuel supply.

13

This document has been printed from SPI². Not for Resale

This document has been printed from SPI². Not for Resale

4

Preventive maintenance

Preventive maintenance periods

These preventive maintenance periods apply to

average conditions of operation. Check the periods

4

given by the manufacturer of the equipment in which

the engine is installed. If necessary, use the shorter

periods. When the operation of the engine must

conform to the local regulations, these periods and

procedures may need to be adapted to ens ure correct

operation of the engine.

The service intervals can be reduced for operation in

advers e conditions. The intervals must not be

extended unless Perkins Engines Company Limited

have approved the changes as indicated in the

Perkins Warranty. It is good preventive maintenance

to check for leakage and loose fasteners at each

service. These maintenance periods apply only to

engines that are operated with fuel and lubricating oil

which conform to the specifications given in this

handbook.

15

This document has been printed from SPI². Not for Resale

4

Schedule for engines in normal use

The preventive maintenance operations must be applied at the interval (hours or months) which occurs first.

A - Every 10 hours or daily

B - Every 400 hours or 12 months

C - Every 1200 hours or 24 months

|

A |

B |

C |

Operation |

|

l l l l |

l l l l l l l l |

l l l l |

Check the amount of coolant Check the level of the lubric ating oil Check the restriction indicators for the air filters and, when necessary, renew the filter elements Drain the water/sediment from the primary fuel filter Check the c ondition and the tension of all drive belts Check the s pecific gravity and the pH value of the coolant Renew the lubricating oil Renew the canisters of the lubricating oil filter Renew the canister of the main fuel filter Clean the primary fuel filter Ensure that the mounting nuts for the turbochargers are tightened securely Check that the air charge cooler and the radiator are clean and free from debris Check the timing of the fuel injection pump Check that the drive coupling bolts of the fuel injection pump are tightened to 120 Nm (88 lbf ft) Ensure that the fuel injectors are c hecked and corrected or renewed, if necessary* Ensure that the tappet clearances are checked and adjusted, if neces sary* |

* By a person who has had the correct training.

In addition to the operations listed above, the operations listed below must be applied at 12 month

intervals:

l Drain and flush the coolant sy stem and renew the coolant mixture

l Check the turbochargers, ensure that they are chec ked and corrected if necessary*

l Ensure that the alternator is checked and corrected if necessary*

16

This document has been printed from SPI². Not for Resale

Schedule for engines in intermittent use

4

For engines which are in use for a total of less than 400 hours in every twelve months, the schedule below

must be used:

The preventive maintenance operations must be applied at the interval (hours or months) whic h occurs first.

A - Monthly

B - Every 200 hours or 12 months

C - Every 1000 hours or 24 months

|

A |

B |

C |

Operation |

|

l l l l l |

l l l l l l l |

l l l l |

Check the amount of coolant Check the level of the lubricating oil Check the restriction indicators for the air filters and, when necessary, renew the filter elements Start and run the engine with 30% load (minimum), until normal temperature of operation is reached Drain the water/sediment from the primary fuel filter Check the condition and the tension of all drive belts Check the specific gravity and the pH value of the coolant Renew the lubricating oil Renew the canis ters of the lubricating oil filter Renew the canister of the main fuel filter Clean the primary fuel filter Ensure that the mounting nuts for the turbochargers are tightened securely Check the timing of the fuel injection pump Check that the drive coupling bolts of the fuel injection pump are tightened to 120 Nm (88 lbf ft) Ensure that the fuel injectors are checked and corrected or renewed, if necessary* Ensure that the tappet clearanc es are checked and adjusted, if necessary* |

* By a person who has had the correct training.

In addition to the operations listed above, the operations listed below must be applied at 12 month

intervals:

l Drain and flush the coolant system and renew the coolant mixture

l Check the turbochargers, ensure that they are checked and corrected if necessary*

l Check that the air charge cooler and the radiator are clean and free from debris

l Ensure that the alternator is checked and corrected if necessary*

17

This document has been printed from SPI². Not for Resale

4

Coolant level

Remove the filler cap from the radiator and check that

the level of the coolant mixture just touches the

bottom of the filler tube inside the radiator. If

neces sary, add coolant until the level of the coolant

reaches the filler tube. Fit the filler c ap.

Caution: If coolant is added to the system during

service, it must consist of the same original mixture as

used to fill the system.

Warning! On a hot engine release the filler cap

carefully as the system will be under pressure.

Lubricating oil level

At the periods given in the service schedule use the

dipstick to check the amount of lubricating oil in the

sump. While the engine runs, the oil level must be

above the L mark. With the engine stopped the oil

level must be at the H mark on the dipstick. If

necessary, put more oil into the sump. Use the same

grade and specification as that already in the system.

Do NOT overfill.