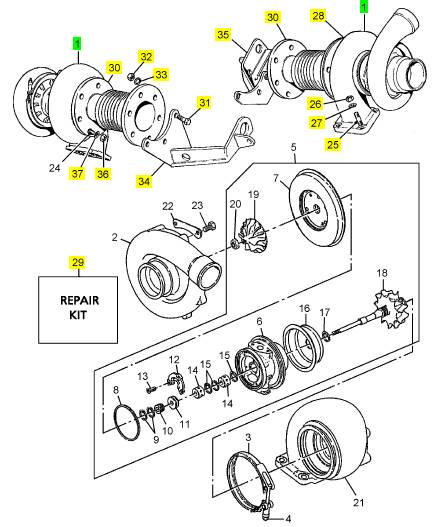

Perkins3012柴油發動機威爾遜P850E柴油發電機配件渦輪增壓器

詳細描述

項目 零配件號碼 最近的部分號碼 描述

1 CV13727/1 Z 2 CV13727/1 Z 渦輪增壓器

25 CV378 8 CV378 圖釘

26 CV235 8 CV235 螺帽

27 2131 A010 8 2131 A010 墊圈

28 CV13795 2 CV13795 密封墊 -排氣

29 KRP1249 1 KRP1249 修補裝備 -渦輪增壓器

30 CV13728 2 CV13728 手風箱

31 ST43604 6 ST43604 螺拴

32 CV1343 6 CV1343 公制的螺帽

33 2131 A012 6 2131 A012 墊圈

34 CV5654 1 CV5654 托架

35 CV5655 1 CV5655 托架

36 CV235 12 CV235 螺帽

37 2131 A010 12 2131 A010 墊圈

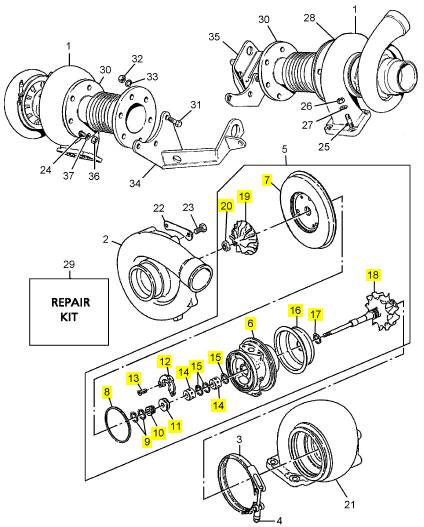

項目 零配件號碼 最近的部分號碼 描述

2 1 殼

3 OE45224 1 OE45224 聯結器

4 CV3017 1 CV3017 鎖緊螺母

5 OE45510 1 OE45510 殼

21 1 殼

22 OE45275 4 OE45275 砂箱夾

23 OE45220 12 OE45220 螺拴

24 CV2533 6 CV2533 圖釘

項目 零配件號碼 最近的部分號碼 描述

6 1 殼

7 OE45507 1 OE45507 背板

8 OE45508 1 OE45508 密封O型圈

9 OE41325 2 OE41325 圈

10 OE45230 1 OE45230 間隔器

11 OE45234 1 OE45234 橋環

12 OE45283 1 OE45283 止推瓦

13 OE45509 3 OE45509 螺旋

14 2 瓦

15 OE45235 3 OE45235 圈

16 OE45281 1 OE45281 復緣

17 CV3005 1 CV3005 圈

18 OE45280 1 OE45280 輪

19 CV9940 1 CV9940 輪

20 OE45188 1 OE45188 鎖緊螺母

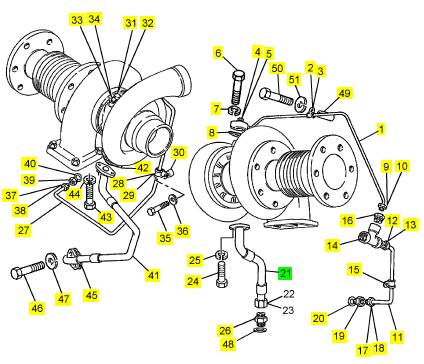

項目 零配件號碼 最近的部分號碼 描述

1 CV13732 1 CV13732 油管

2 OE9691 2 OE9691 夾

3 OE9692 2 OE9692 襯套

4 ST46076 1 ST46076I 栓塞

5 ST49851 1 ST49851 墊圈

6 ST44444 2 ST44444 固定螺釘

7 2134 A008 2 2134 A008 墊圈

8 DV807 2 OE50898 密封墊

9 ST46007 1 ST46007 套筒

10 ST46032 1 ST46032 螺帽

11 CV12871 1 CV12871 油管

12 ST46008 1 ST46008 套筒

13 ST46033 1 ST46033 螺帽

14 ST46183 1 ST46183 TEEPIECE

15 OE9691 1 OE9691 夾

16 ST46269 1 ST46269 異徑管接合器

17 ST46008 1 ST46008 套筒

18 ST46033 1 ST46033 螺帽

19 ST49459 1 ST49459 承接器

20 ST49891 1 ST49891 墊圈

21 CV13733 1 CV13733 油管

24 2314 C044 2 2314 C044 固定螺釘

25 2134 A008 2 2134 A008 墊圈

26 ST20557 1 ST20557 承接器

27 CV13729 1 CV13729 油管

28 OE9691 1 OE9691 夾

29 OE9692 1 OE9692 襯套

30 CV1726 1 CV1726 距離塊

31 ST46076 1 ST46076I 栓塞

32 ST49851 1 ST49851 墊圈

33 ST44444 2 ST44444 固定螺釘

34 2134 A008 2 2134 A008 墊圈

35 ST43506 1 ST43506 螺拴

36 2134 A008 1 2134 A008 墊圈

37 ST46007 1 ST46007 套筒

38 ST46032 1 ST46032 螺帽

39 ST49449 1 ST49449 承接器

40 ST49853 1 ST49853 墊圈

41 CV17106 1 CV17106 油管

42 OE50899 2 OE50899 切片密封墊的板

43 2314 C044 2 2314 C044 固定螺釘

44 2134 A008 2 2134 A008 墊圈

45 CV20236 1 CV20236I 密封墊

46 ST43556 2 ST43556 螺拴

47 2134 A010 2 2134 A010 墊圈

48 ST49891 1 ST49891 墊圈

49 CV7361 2 CV7361 距離塊

50 ST43511 2 ST43511 螺拴

51 2134 A008 2 2134 A008 墊圈

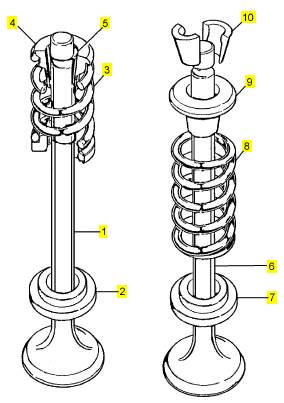

項目 零配件號碼 最近的部分號碼 描述

1 CV17435 24 CV21058 進氣門

2 OE43638 24 OE43638 位子

3 CV11403 24 CV11403 閥彈簧

4 OE43262 24 OE43262 位子

5 OE42571 48 OE42571 閥筒夾

6 CV17434 24 排氣閥

7 OE43638 24 OE43638 位子

8 CV11403 24 CV11403 閥彈簧

9 CV18761 24 CV18761 回轉的人

10 OE42570 48 OE42570 閥筒夾

Contents

1 General information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

How to care for your engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Engine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Perkins companies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety pr ecautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Engine views

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Location of engine parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Operation instructions

Pr epar ations for a new or an overhauled engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to start a new or overhauled engine or an engine which has been in storage . . . . 12

Normal start procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to start the engine in low ambient temper atures . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pr ecautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

How to stop the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Preventive maintenance

Pr eventive maintenance periods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Schedule for engines in nor mal use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Schedule for engines in intermittent use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Coolant level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lubr icating oil level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Restriction indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to renew the elements of the air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to drain the prim ary fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

How to check the drive belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to renew the fan belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to renew the alternator belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

How to check the specific gravity of the coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to check the pH value of the coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to renew the engine lubr icating oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

How to renew the canisters of the oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Continued

3

This document has been printed from SPI². Not for Resale

How to clean the primary fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to renew the canister of the main fuel filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to check/adjust the tim ing of the fuel injec tion pump . . . . . . . . . . . . . . . . . . . . . . . . 24

Fuel injector fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to remove the fuel injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to correct the fuel injector sleeves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to fit the fuel injec tor s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

How to eliminate air from the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How to check the tappet clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Turbochargers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Alter nator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to drain the c oolant s ystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to clean the c oolant system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to fill the coolant system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 Engine fluids

Diesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Lubricating oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recommended oils for Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Recommended oils for remainder of the world . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6 Fault diagnosis

Problems and possible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Code list of poss ible causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Engine preservation

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Short period storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Long period storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Removal from storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Approved products for engine preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 Parts and Service

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service liter ature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Service Bulletins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 Engine data

3012 diesel engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4

This document has been printed from SPI². Not for Resale

1

General information

Introduction

The 3012 heavy duty diesel engine is the latest

development from Perkins Engines Company

1

How to care for your engine

Limited, a world leader in the design and manufacture

of high performance diesel engines.

More than fifty years of diesel production experience,

together with the use of the latest technology, have

been used in the manufacture of your engine to give

you reliable and economic power.

To ensure that you use the correct information for

your specific engine type, refer to ‘Engine

identification’ on page 6.

Danger is indicated in the text by two methods:

Warning! This indicates that there is a possible

danger to the person.

Caution: This indicates that there is a possible

danger to the engine.

Note: Is used where the information is important, but

there is not a danger.

This handbook has been written to assist you to

maintain and operate your engine correctly.

To obtain the best performance and the longest life

from your engine, you must ensure that the

maintenance operations are done at the intervals

shown in ‘Preventive maintenance’. If the engine is

operated in a very dusty environment or other

advers e conditions, certain maintenance intervals will

have to be reduced. Renew the filter elements and the

lubricating oil regularly to ensure that the inside of

your engine remains clean.

Ensure that all adjustments and repairs are done by

personnel who have had the correct training. Perkins

distributors have this type of personnel available. You

can also obtain parts and service from your Perkins

distributor. If you do not know the address of your

nearest distributor, enquire at one of the Perkins

companies listed on page 7.

The left and right sides of the engine are as seen from

the rear (flywheel) end. Where reference is made to

‘A’ and ‘B’ banks of cylinders: ‘A’ bank is to the right

and ‘B’ bank is to the left when viewed from the rear

end.

Read the ‘Safety precautions’ and remember

them. They are given for your protection and must

be applied at all times.

5

This document has been printed from SPI². Not for Resale

1

Engine identification

If you need parts, service or information for your

engine, you must give the complete engine number to

your Perkins distributor.

The engine number is stamped on the data plate

which is fastened to the left side of the crankcase.

For early engines, a typical engine number is:

6A27487U 59426U, which consists of these codes:

6A = Engine family

27487 = Engine number

U = Country of manufacture

59426 = Build line number

U = Year of manufacture

Engines made after August 1994, have a new engine

number system. For these engines, a typical number

is: SGJ 12 0029 U 3254 C, which consists of these

codes:

SG = Engine application

J = Engine type

12 = Number of engine cylinders

0029 = Engine specification number

U = Country of manufacture

3254 = Build line number

C = Year of manufacture

Units such as the fuel injection pump and

turbochargers have their own data plates.

6

This document has been printed from SPI². Not for Resale

Perkins companies

Australia

Perkins Engines Australia Pty. Limited,

Suite 4, 13A Main Street,

Mornington, Victoria 3931, Australia.

Telephone: 0061 (0)597 51877

Telex: Perkoil AA 30816

Fax: 0061 (0)597 1305

China

Perkins Engines (Tianjin) Limited,

Jinwei Road,

Beichen District, Tianjin,

300402

China

Telephone: (86) (22) 2699 2288

Fax: (86) (22) 2699 3784

France

Perkins France SAS,

"Parc des reflets",

165 Avenue du Bois de la Pie,

95700 Roissy Charles de Gaulle, France.

Telephone: 0033 (01) 49-90-7171

Fax: 0033 (01) 49-90-7190

Germany

Perkins Motoren G.m.b.H.,

Saalaeckerstrasse 4,

63801 Kleinostheim,

Germany.

Telephone: 0049 6027 5010

Fax: 0049 6027 501124

Italy

Motori Perkins S.p.A.,

Via Socrate 8

22070 Casnate con Bernate (Como), Italy.

Telephone: 0039 (0)31 564625/564633

Fax: 0039 (0)31 565480/564145/396001

Japan

Perkins Engines, Inc. Japan Branch,

8 Fl, 2-2-19 Akasaka, Minato-ku,

Tokyo 107-0052, Japan.

Telephone: 0081 (0)3 3560 3877

Korea

Perkins Engines (Korea)

Textile Center 12F

Daechi 3 dong 944-31

Kangnam-Ku

Seoul, 135-283

Korea

Telephone: (822) 528 3377

Fax: (822) 528 3378

Singapore

Perkins Engines (Asia Pacific ) Pte. Limited,

20 Harbour Drive,

#07-06A, PSA Vista,

Singapore 117612.

Telephone: (65) 874 7712

Fax: (65) 874 7722

United Kingdom

Perkins Engines Company Limited,

Lancaster Road, Shrewsbury, SY1 3NX,

England.

Telephone: 0044 (0)1743 212000

Telex: 35171 PESL G

Fax: 0044 (0)1743 212700

United States of America

Perkins Engines - North America

12025, Tech Center Drive

Livonia

Michigan 48150

USA

Telephone: 001 313 266 5427

Fax: 001 313 266 2700

Perkins Engines Latin America Inc,

Suite 620,

999, Ponc e de Leon Boulevard,

Coral Gables,

Florida 33134,

USA.

Telephone: 001 305 442 7413

Telex: 32501 Perken G

Fax: 001 305 442 7419

In addition to the above companies, there are

1

Fax: 0081 (0)3 3560 3878

Perkins distributors in most countries. Perkins

Engines Company Limited, Shrewsbury or one of

the above companies can provide details.

7

This document has been printed from SPI². Not for Resale

1

Safety precautions

These safety precautions are important.

Reference must also be made to the local regulations

in the country of operation.

l Only use these engines in the type of application

for which they have been designed.

l Do not change the specification of the engine.

l Do not smoke when you put fuel in the tank .

l Clean away fuel which has been spilt. Material

which has been contaminated by fuel must be

moved to a safe place.

l Do not put fuel in the tank while the engine runs

(unless it is absolutely necessary).

l Do not clean, add lubricating oil, or adjust the

engine while it runs (unless you have had the

correct training; even then extreme caution must

be used to prevent injury).

l Do not make adjustments that you do not

understand.

l Ensure that the engine does not run in a location

where it c an cause a concentration of toxic

emissions.

l Other persons must be kept at a safe distance

while the engine or equipment is in operation.

l Do not permit loose clothing or long hair near

moving parts.

l Keep away from moving parts during engine

operation. Warning! Some moving parts cannot

be seen clearly while the engine runs.

l Do not operate the engine if a safety guard has

been removed.

l Do not remove the filler cap of the cooling system

while the engine is hot and while the coolant is

under pressure, because dangerous hot coolant

can be discharged.

l Do not use salt water or any other c oolant which

can cause corrosion in the closed coolant circ uit.

l Do not allow sparks or fire near the batteries

(especially when the batteries are on charge)

because the gases from the electrolyte are highly

flammable. The battery fluid is dangerous to the

skin and especially to the eyes.

l

l

l

l

l

l

l

l

l

l

l

Disconnect the battery terminals before a repair is

made to the electrical system.

Only one person must control the engine.

Ensure that the engine is operated only from the

control panel or from the operator’s position.

If your skin comes into contact with high-pressure

fuel, obtain medical assistance immediately.

Diesel fuel and lubricating oil (especially used

lubricating oil) can damage the skin of certain

persons. Protect your hands with gloves or a

special solution to protect the skin.

Do not wear clothing which is contaminated by

lubricating oil. Do not put material which is

contaminated with oil into the pockets.

Discard used lubricating oil in a safe place to

prevent contamination.

Ensure that the control lever of the transmission

drive is in the ‘out-of-drive’ position before the

engine is started.

The combustible material of some components of

the engine (for example certain seals) can

become extremely dangerous if it is burned. Never

allow this burnt material to come into contact with

the skin or with the eyes.

Fuel and oil pipes MUST be inspected for cracks

or damage before they are fitted to the engine.

Fit only genuine Perkins parts.

8

This document has been printed from SPI². Not for Resale

2

2

Engine views

Introduction

2

Perkins engines are built for specific applications and

the views which follow do not necessarily match your

engine specification.

Location of engine parts

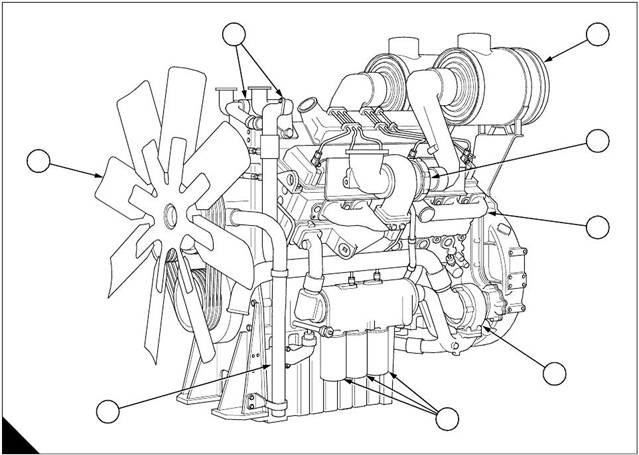

Front and left side view of the 3012 engine

1 ‘B’ bank air cleaner

2 ‘B’ bank turbocharger

3 Exhaust manifold

4 Coolant pump

5 Canisters of the lubricating oil filter

6 Crankcase breather

7 Fan

8 Thermos tat housings

8

1

7

2

3

A

6

5

4

482

9

This document has been printed from SPI². Not for Resale

2

2

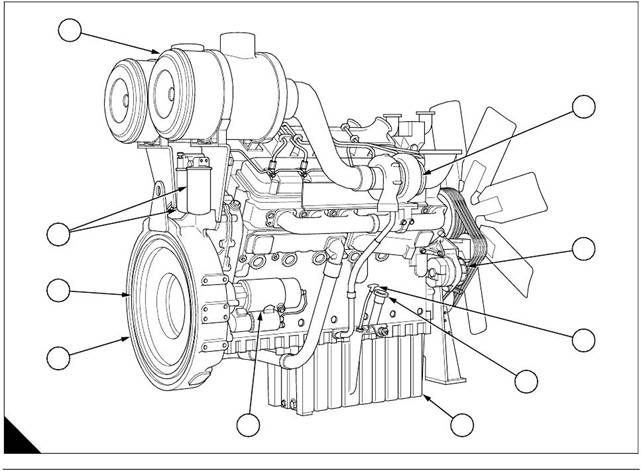

Rear and right side view of the 3012 engine

1 ‘A’ bank turbocharger

2 Alternator

3 Dipstick

4 Filler cap for lubricating oil

5 Lubricating oil sump

6 Starter motor

7 Flywheel housing

8 Flywheel

9 Canisters of the fuel filter

10 ‘A’ bank air cleaner

10

1

9

2

8

7

4

3

B

6

5

483

10

This document has been printed from SPI². Not for Resale

3

3

Operation instructions

3

|

|

|

|

|

Every new engine supplied by Perkins Engines

Company Limited, Shrewsbury, is run-in before it

leaves the factory.

1 Check that all protection covers and blanking plugs

have been removed.

2 Fit all components that were removed for storage

or for transport.

3 Ensure that drain plugs for coolant and for

lubricating oil are securely fitted.

4 Where necessary, connect the remote control

link ages, the pressure gauge pipes, the air inlet pipes

and the wiring loom.

5 Connect the fuel pipes.

6 Connect the exhaust pipes.

7 Fill the fuel tank(s) with the correct grade of fuel

(see page 31).

8 Fill the cooling system with the approv ed coolant

mixture (see page 31).

9 Fill the sump to the H mark on the dipstick with the

correct grade of lubricating oil (see page 32).

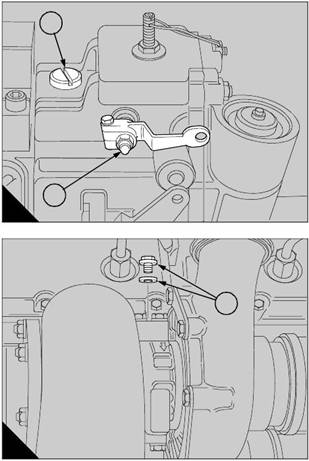

10 Clean the area around the plug (A1) on the

governor housing of the injection pump and remove

clean engine oil of the correct grade (see page 32) to

the governor housing. Fit and tighten the plug

securely.

11 Add oil to the turbochargers as follows: Clean the

area around the blanking plug (B1) on the bearing

housing of each turbocharger. Remove the plugs (B1)

grade to each turbocharger. Fit and tighten the plugs.

12 Eliminate air from the fuel system (see page 27).

13 Lubricate all of the control linkages and check the

link ages for free movement.

A

B

1

2

1

57

58