John Deere約翰迪爾強鹿柴油發動機氣門座圈拆卸、磨氣門座圈的方法

詳細描述

John Deere約翰迪爾強鹿柴油發動機氣門座圈拆卸、磨氣門座圈的方法

1. Use an electric hand drill with D17024BR End Brush toremove all carbon on valve seats.

2. Inspect seats for excessive wear, cracks, or damage.

3. Check entire combustion face for rust, scoring, pitting,or cracks.

IMPORTANT: Valve seat grinding should only bedone by experienced personnel familiarwith equipment and capable ofmaintaining required specifications.ALWAYS keep valve guides and workarea clean when grinding valve seats tomaintain valve guide bore-to-seatrunout.

Grinding valve seats increases seatwidth and valve recess in cylinder head.DO NOT grind excessively. Only a fewseconds are required to recondition theaverage valve seat. Dress grindingstone as necessary to maintain

specified seat angle.Support the weight of grinder to avoidexcessive pressure on the stone.Blend or radius all sharp edges aftergrinding valve seats for a more effective

valve face-to-seat seal.

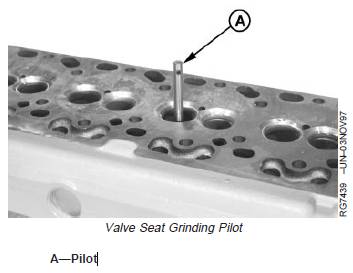

1. Install appropriate pilot (A) in valve guide bore.

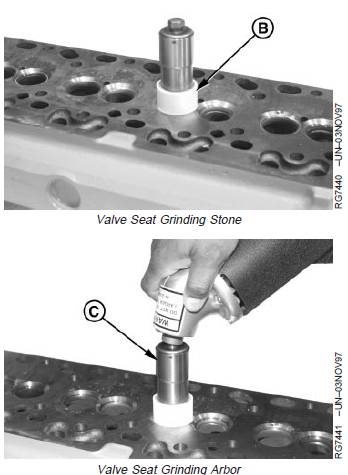

2. Install appropriate grinding stone (B) on arbor (C) andposition onto valve seat.

B—Grinding Stone

C—Arbor

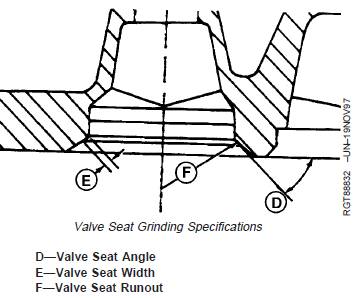

3. Using drill from JT05893 Heavy-Duty Seat Grinder Set,grind valve seats to the following specifications:

Specification

Valve Seat Grinding—Seat Angle(D).......................................................................................................... 30°

Valve Seat Width (E)........................... 1.50—2.00 mm (0.059—0.079 in.)

Maximum Valve Seat Runout (F)............................... 0.08 mm (0.003 in.)

4. Use a vernier caliper or scale to measure seat width. Ifvalve seat is too wide, reduce the width with anarrowing stone.

NOTE: A narrowing stone will change the top angle of theseat and reduce the outer diameter of the valve

seating area. Varying the width changes the finecontact between valve face and seat. If seat widthis too narrow, valve may burn or erode.

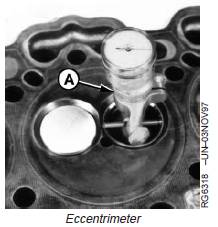

5. If valve does not seat properly, use an eccentrimeter(A) to check valve seat runout. Use a new or refacedvalve and blueing to check contact between valve seatand face. If necessary, lap the valve onto its seat usinga lapping tool and lapping compound. Replace valvesand inserts as necessary.

6. Install new or refaced valve and check valve recess incylinder head after grinding. (See MEASURE VALVERECESS IN CYLINDER HEAD earlier in this group.)

A—Eccentrimeter

Remove Valve Seat InsertsIMPORTANT: Be careful not to damage cylinder headwhen removing valve seats. Valve seatremoval should only be done byexperienced personnel familiar with

procedures.DO NOT use an oxy-acetylene torch toremove valve seat inserts, as it altersthe hardness of the cylinder head.

Valve seat inserts are made of sintered (powdered) metal.Remove inserts by one of the following methods:

氣門座圈拿出的方法

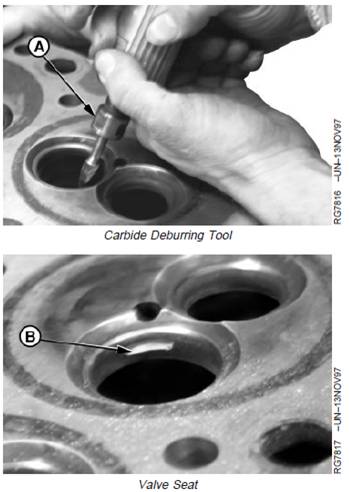

1. Using a carbide deburring tool (A), raise a burr (B) onbottom of valve seat insert.

A—Deburring Tool

B—Burr

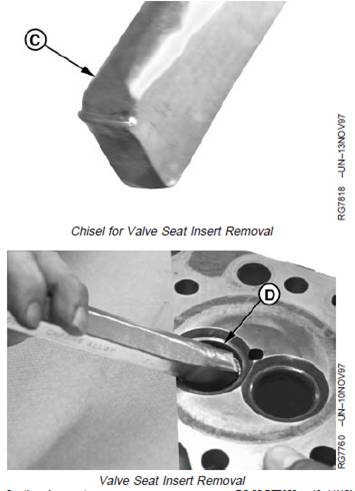

2. Protect surface of cylinder head with cardboard orcloth. Using a chisel with special ground end (C), taphandle of chisel with hammer until valve seat insert (D)comes loose.

C—Special Ground Chisel

D—Valve Seat Insert