產(chǎn)品中心

美國強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

英國珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國道依茨 韓國大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

John Deere約翰迪爾強(qiáng)鹿柴油發(fā)動(dòng)機(jī)缸套突出量的測(cè)量方法與標(biāo)準(zhǔn)值參數(shù)

詳細(xì)描述

John Deere約翰迪爾強(qiáng)鹿柴油發(fā)動(dòng)機(jī)缸套突出量的測(cè)量方法與標(biāo)準(zhǔn)值參數(shù)

1. Secure liners using cap screws and flat washers. Flatwashers should be at least 3.18 mm (1/8 in.) thick.Tighten cap screws to 68 N•m (50 lb-ft).

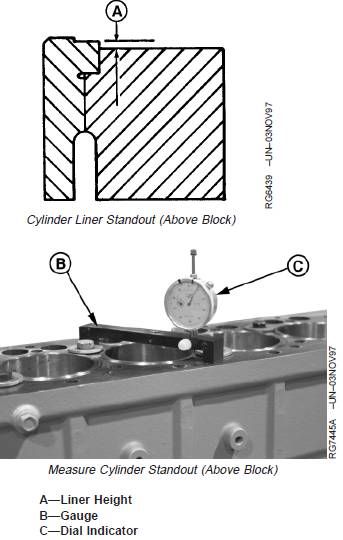

2. Using JDG451 or KJD10123 Gauge (B) and D17526CIor D17527CI Dial Indicator (C), measure liner height

(A) at 1, 5, 7, and 11 o’clock positions as viewed fromflywheel end of engine. Record all measurements bycylinder number.

Specification

Cylinder Liner—Height aboveBlock 0.030—0.100 mm(0.001—0.004 in.)

Maximum Permissible HeightDifference at Nearest Point ofTwo Adjacent Liners, or Within a

Single Liner................................................................. 0.05 mm (0.002 in.)

IMPORTANT: ONE LINER SHIM ONLY may beinstalled under each liner flange.

3. Remove and shim, or replace, any liner that does notmeet height specifications. (See REMOVE CYLINDERLINERS in Group 030.)

NOTE: Two sizes of shims are available: 0.05 mm (0.002in.) and 0.10 mm (0.004 in.).

氣缸蓋的安裝

1. Dip fuel supply pump push rod (A) (if equipped) inclean engine oil and carefully install in cylinder blockbefore installing cylinder head.

A—Fuel Supply Pump Push Rod

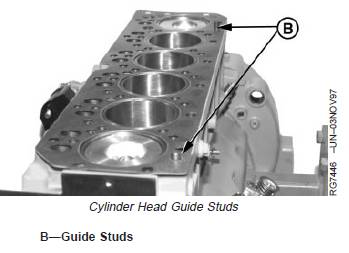

IMPORTANT: The O-ring seals in head gasket can bedamaged if head is repositioned whileresting on engine block. Use guidestuds to position cylinder head onblock.

2. Install two guide studs (B) in cylinder block at locatingholes.

IMPORTANT: ALWAYS thoroughly inspect cylinderhead gasket for possible manufacturingimperfections. Return any gasket thatdoes not pass inspection.

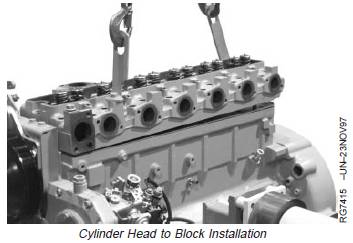

3. Place new head gasket on cylinder block. Do not usesealant; install dry.

4. Position cylinder head over guide studs and lower ontocylinder block.

5. Dip entire cap screw in clean engine oil. Removeexcess oil from screw.

6. Remove guide studs. Install flanged-head cylinderhead cap screws.

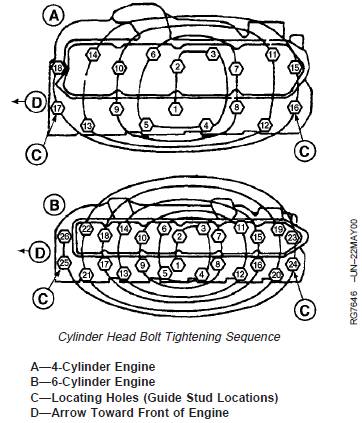

7. Tighten all cap screws to specified torques (insequence shown, beginning with No. 1), followingsteps 1—4 below. Then, torque-turn cap screwsfollowing procedure on next page.

Cylinder Head Cap Screws—Specification

Step 1—Initial—Torque ................................................. 100 N•m (75 lb-ft)

Step 2—Second—Torque ........................................... 150 N•m (110 lb-ft)

Step 3—Verify (After 5Minutes)—Torque........................................................ 150 N•m (110 lb-ft)

Step 4—Final—Torque-Turn Tighten each screw an additional60° ± 10°. (See TORQUE-TURNMETHOD FOR PROPERTORQUE in this group.)

Retorque of cylinder head cap screws after enginebreak-in is not required when using the recommendedtorque procedure along with flanged-head cap screw.