John Deere強鹿柴油機曲軸與曲軸瓦的安裝方法

詳細描述

John Deere約翰迪爾強鹿柴油機曲軸與曲軸瓦的安裝方法

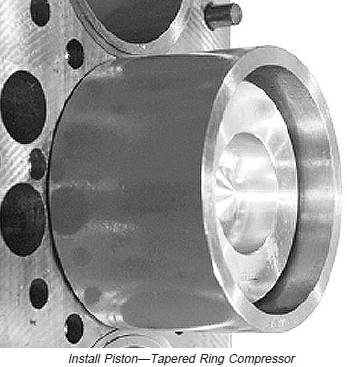

IMPORTANT: Be careful so crankshaft journals and liner walls are not damaged by connecting rod when installing piston and rod in liner.

1. Coat pistons, liners and inside of piston ring compressor with clean engine oil.

2. Carefully place JDE84 Piston Ring Compressor withpiston and rod over liner so the word “FRONT” on sideof rod and on the side of piston faces toward the frontof the engine.

NOTE: Be sure the word “FRONT” on connecting rodfaces toward the front of the engine.If arrow indicating “FRONT” is not visible on top ofpistons, install piston and rod so combustion bowlin piston is offset toward fuel injection pump sideof engine, and the long side of the connecting rodis toward camshaft side of engine.

3. With piston centered in ring compressor and ringsstaggered correctly, push piston down until top ring isinto liner.

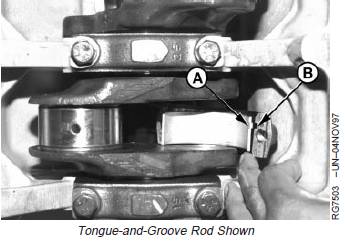

4. Install bearing insert in connecting rod with tang (A) ingroove (B).

5. Apply clean engine oil on insert and crankshaft journal.Carefully pull connecting rod and insert againstcrankshaft journal.

A—Tang

B—Groove

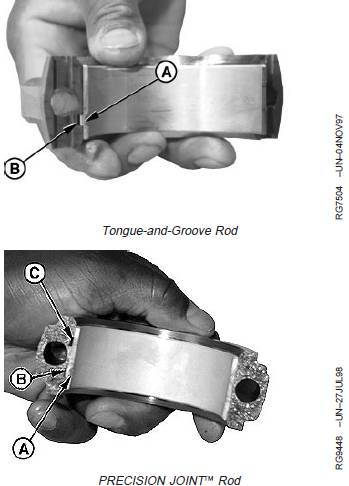

NOTE: Due to the manufacturing process, thePRECISION JOINTä rod and cap both have twogrooves, while the bearing insert has a singletang. Only the one groove in the rod and cap isused for the bearing tang.

6. Install bearing insert in connecting rod cap with tang(A) in groove (B).

IMPORTANT: On PRECISION JOINTä connectingrods, make sure cap is properly alignedon rod with edges flush andinterlocking surfaces sealed tightly.

7. Apply clean engine oil to bearing insert. Install cap onconnecting rod with tangs to same side.

A—Tang

B—Groove

C—Extra Groove (Not Used)

IMPORTANT: NEVER use connecting rod cap screwsmore than once for final engineassembly. Once rod cap screws havebeen tightened to final torque-turnspecification, they must not be reusedfor another final assembly.

Cap screws for PRECISION JOINTä rodand cap are 3 mm shorter thantongue-and-groove cap screws. DO NOT

mix hardware.

Two types of connecting rods and capsmay be used within the same engine,however the correct cap screws mustbe used for each type of connectingrod.

8. Dip NEW connecting rod cap screws in clean oil andinstall.

9. Tighten cap screws alternately to initial torquespecification.

Specification

Connecting Rod Cap Screws—Initial Torque.................................................................... 58 N•m (43 lb-ft)

10. Then, torque-turn all cap screws to 90—100 degrees.(See TORQUE-TURN CONNECTING ROD CAPSCREWS next in this group.)

John Deere約翰迪爾強鹿柴油機活塞突出量的測量與標準值參數

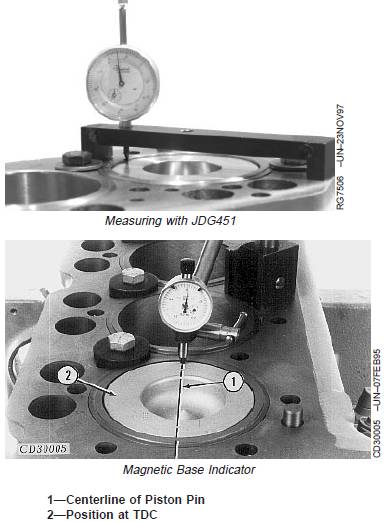

1. Press down on top of piston to remove oil clearances before measuring piston protrusion.

NOTE: If JDG451 or KJD10123 are not available, a dial indicator with magnetic base can be used to measure piston protrusion.

2. Use JDG451 or KJD10123 Height Gauge (or use a magnetic base dial indicator) to measure piston protrusion. Place gauge on top of cylinder block so dial indicator can be set to “zero” with top of block.

3. Position gauge across piston as close to centerline of piston pin as possible. While pressing gauge downward, rotate crankshaft until piston is at TDCposition. Measure piston height at several positions around the outermost diameter of piston. Piston height must be checked at outermost diameter of piston.

4. Piston protrusion must be within specifications to prevent piston-to-exhaust valve contact.

5. Measure piston protrusion and compare to the following specifications. If protrusion does not meet specifications, check dimensions of piston, connecting rod, cylinder block, crankshaft, and bearings to determine the cause.

Piston Protrusion—Specification

4-Cyl. Standard Duty

Codes 4801, 4803, 4809.

6-Cyl. Standard Duty

Codes 4805, 4807.—Piston

Protrusion 0.08—0.31 mm (0.003—0.012 in.)

4-Cyl. Heavy Duty

Code 4804.

6-Cyl. Heavy Duty

Codes 4808, 4810 and All

Four-Valve Head Engines.—Piston Protrusion 0.08—0.25 mm (0.003—0.010 in.)

Complete Final Assembly

1. Install oil pump outlet tube O-ring in cylinder block.Install oil pump and outlet tube. (See INSTALLENGINE OIL PUMP in Group 060.)

2. Install balancer shaft bushings (4-cylinder engines).(See REMOVE AND INSTALL BALANCER SHAFTBUSHINGS in Group 050.)

3. Install camshaft bushings. (See REMOVE ANDINSTALL CAMSHAFT BUSHINGS in Group 050.)

4. Install oil bypass valve (in front of block) and frontplate. (See INSTALL CYLINDER BLOCK FRONTPLATE in Group 050.)

5. Install balancer shafts (if equipped). (See INSTALLAND TIME BALANCER SHAFTS in Group 050.)

6. Install camshaft and timing gears. (See INSTALLCAMSHAFT in Group 050.)

7. If equipped with cartridge type oil pressurregulating valve, install valve. (See REMOVE AND

INSTALL OIL PRESSURE REGULATING VALVE inGroup 060.)

8. Install timing gear cover. (See INSTALL TIMINGGEAR COVER in Group 050.)

9. If equipped with spring, plunger and seat type oilpressure regulating valve, install valve assembly.(See REMOVE AND INSTALL OIL PRESSUREREGULATING VALVE in Group 060.)

10. Install oil pan. (See INSTALL OIL PAN in Group060.)

11. Install crankshaft pulley. (See INSTALL PULLEYOR VIBRATION DAMPER PULLEY in Group 040.)

12. Install camshaft followers. (See INSPECT,MEASURE AND ASSEMBLE CAMSHAFTFOLLOWERS in Group 050.)

13. Install cylinder head with new gasket. (SeeINSTALL CYLINDER HEAD in Group 020 for twovalve head or INSTALL CYLINDER HEAD inGroup 021 for four valve head.)

14. Fill engine with clean oil and proper coolant.

15. Perform engine break-in. (See PERFORMENGINE BREAK-IN in Group 010.)