珀金斯珀金斯403F-15T、404F-22、404F-22T維修保養測試調整(英文)一

詳細描述

Systems Operation

Testing and Adjusting

403F-15T, 404F-22 and 404F-22T

Industrial Engines

EL (Engine)

EN (Engine)

EP (Engine)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

Important Safety Information

Most accidents tha t involve produc t op eration, ma intena nc e and repair are caus ed by failure to

ob serve basic safety rules or precautions . An accident can often be avoided by recog nizing pote ntially

ha za rdous situations before an accident oc curs . A person mus t be alert to pote ntial ha za rds. This

person should also ha ve the ne cessary training, skills and tools to perform the se func tions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Sa fety precautions and warning s are provided in this ma nua l and on the produc t. If the se ha za rd

warning s are not he eded, bod ily injury or death could oc cur to you or to othe r persons .

The ha za rds are identified by the “Safety Alert Symb ol” and followed by a “Signa l Word” suc h as

“DANGER”, “WARNING” or “CAUTION”. The Sa fety Alert “WARNING” label is shown below.

The me aning of this safety alert symb ol is as follows:

Attention! Become Alert! Your Safety is Involved.

The me ssage tha t appears und er the warning explains the ha za rd and can be either written or

pictorially presente d.

Op erations tha t ma y caus e produc t dama ge are identified by “NOTICE” labels on the produc t and in

this pub lication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The informa tion, specifications , and illustrations in this pub lication are on the basis of informa tion tha t

was available at the time tha t the pub lication was written. The specifications , torque s, pressure s,

me asure me nts , adjustme nts , illustrations , and othe r items can cha ng e at any time. These cha ng es can

affect the service tha t is given to the produc t. Ob tain the comp lete and mos t current informa tion before

you start any job. Pe rkins dealers or Pe rkins distributors ha ve the mos t current informa tion available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

3

Table of Contents

Table of Contents

Water Pump - Inspect................... .................. 73

Basic Engine

Systems Operation Section

Piston Ring Groove - Inspect............. ............. 75

Connecting Rod - Inspect................ ............... 75

Connecting Rod Bearings - Inspect........ ........ 76

Main Bearings - Inspect................. ................. 76

Cylinder Block - Inspect................. ................. 76

Cylinder Head - Inspect................. ................. 77

Piston Height - Inspect.................. .................. 77

Flywheel - Inspect...................... ..................... 78

Flywheel Housing - Inspect .............. .............. 79

Gear Group - Inspect................... ................... 80

General Information..................... ..................... 4

Glossary of Electronic Control Terms ....... ...... 10

Electronic Control System Components..... .... 14

Fuel System.......................... .......................... 31

Air Inlet and Exhaust System............. ............. 35

Clean Emissions Module................ ................ 37

Lubrication System..................... .................... 40

Cooling System ....................... ....................... 41

Basic Engine.......................... ......................... 42

Electrical System...................... ...................... 43

Electrical System

Alternator - Test ....................... ....................... 81

Battery - Test.......................... ......................... 82

Charging System - Test ................. ................. 82

Coolant Temperature Switch - Test......... ........ 82

Electric Starting System - Test............ ............ 82

Engine Oil Pressure Switch - Test ......... ......... 83

Fuel Shutoff Solenoid - Test.............. .............. 83

Glow Plugs - Test...................... ...................... 84

Testing and Adjusting Section

Fuel System

Fuel System - Inspect................... .................. 46

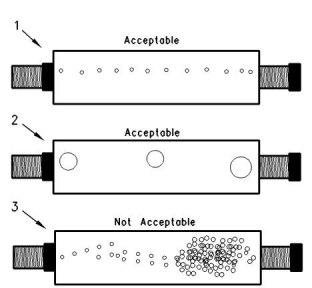

Air in Fuel - Test....................... ....................... 46

Finding Top Center Position for No. 1 Piston. . 47

Fuel Injection Timing - Check ............. ............ 47

Fuel Transfer Pump - Test ............... ............... 48

Fuel Injector - Test ..................... ..................... 49

Fuel Quality - Test...................... ..................... 52

Fuel System - Prime.................... ................... 52

Gear Group (Front) - Time............... ............... 52

Governor - Adjust...................... ...................... 52

Index Section

Index................................ ............................... 86

Air Inlet and Exhaust System

Air Inlet and Exhaust System - Inspect...... ..... 59

Diesel Particulate Filter - Clean........... ........... 59

Wastegate - Test....................... ...................... 60

Exhaust Cooler (NRS) - Test (If Equipped)... .. 61

Compression - Test..................... .................... 62

Engine Valve Lash - Inspect/Adjust........ ........ 62

Valve Depth - Inspect................... ................... 65

Valve Guide - Inspect................... ................... 66

Lubrication System

Engine Oil Pressure - Test............... ............... 67

Engine Oil Pump - Inspect............... ............... 67

Excessive Bearing Wear - Inspect......... ......... 68

Excessive Engine Oil Consumption - Inspect. 69

Cooling System

Cooling System - Check (Overheating)..... ..... 70

Cooling System - Inspect................ ................ 71

Cooling System - Test................... .................. 71

Water Temperature Regulator - Test........ ....... 73

This document is printed from SPI². Not for RESALE

![]()

4

KENR9144

Systems Operation Section

Systems Operation Section

The engine oil pump is a gerotor type pump. The

engine oil pump is located in the center of the idler

gear. The engine oil pump sends lubricating oil to the

main oil gallery through an oil relief valve that is

located on the right side of the cylinder block. The

rocker arm levers receive pressurized oil through an

externally located oil line. The oil line runs from the

main oil gallery to the cylinder head.

i04903822

General Information

Coolant from the bottom of the radiator passes

through the belt driven centrifugal water pump. The

coolant is cooled by the radiator and the temperature

is regulated by a water temperature regulator.

Engine Description

Note: When you are ordering new parts, refer to the

engine identification number in order to receive the

correct parts. Refer to the Operation and

Maintenance Manual, “Product Identification

Information” for the correct numbers for your engine.

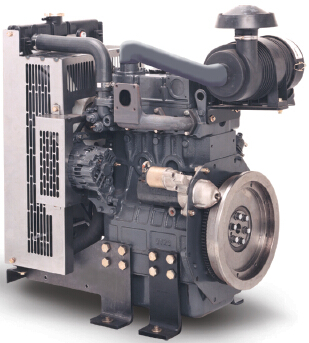

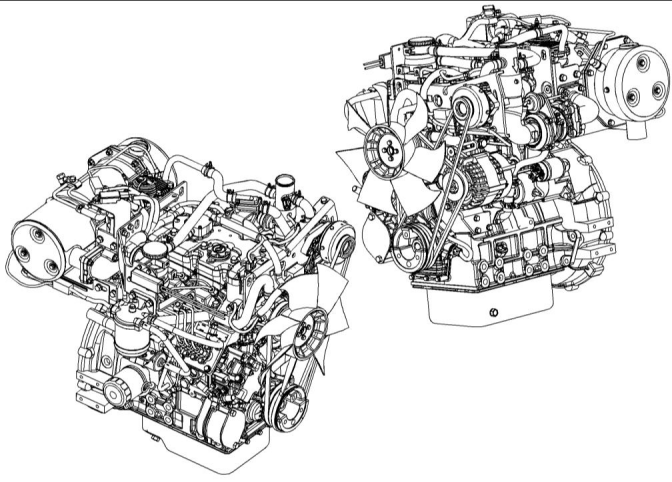

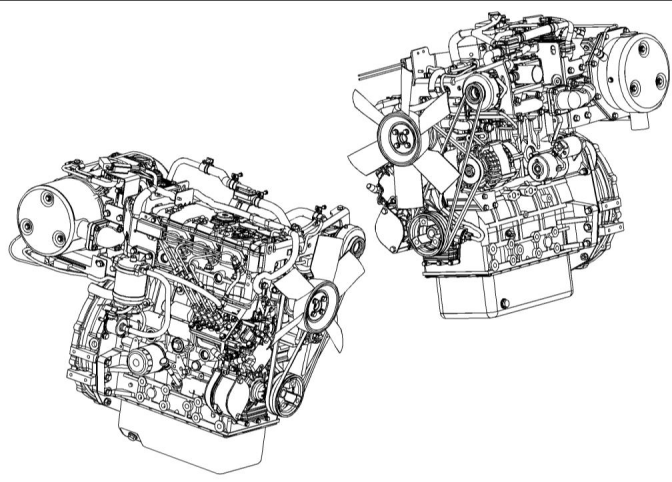

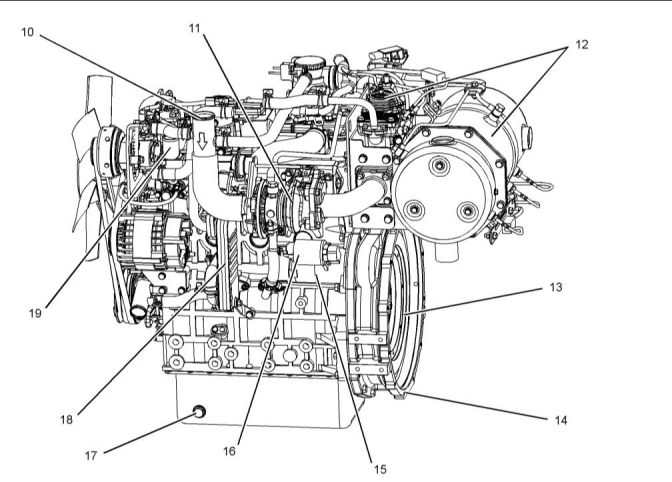

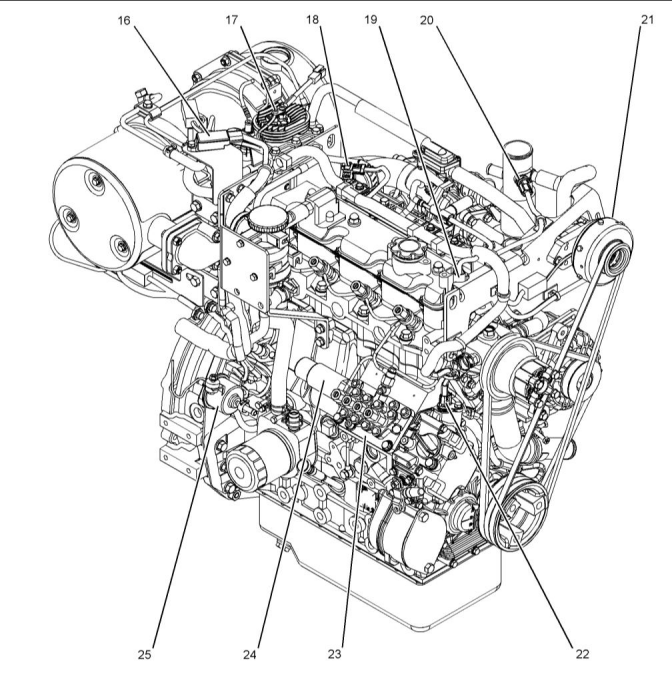

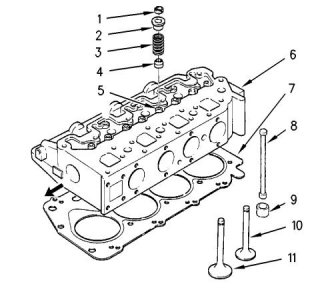

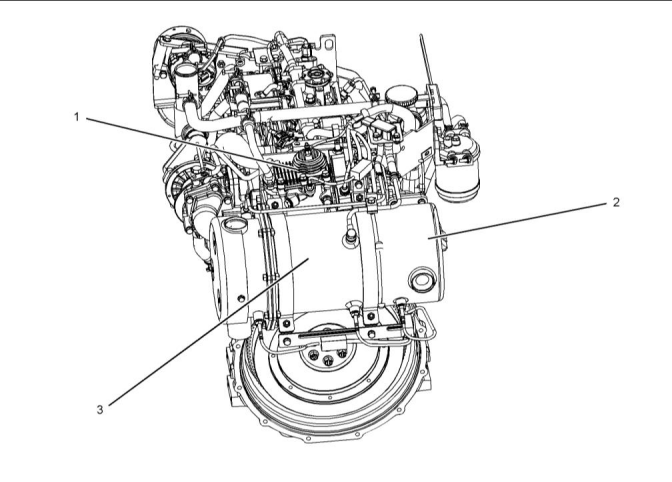

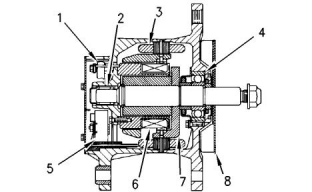

Engine Model Views

The following model views show typical features of

the 403F-15T, 404F-22, and 404F-22T engines. Due

to individual applications, your engine may appear

different from the illustrations.

The 403F-15T, 404F-22, and 404F-22T engines are

diesel engines that are controlled with a mechanically

actuated fuel injection pump. The engine cylinders

are arranged in-line.

The cylinder head assembly has one inlet valve and

one exhaust valve for each cylinder. Each cylinder

valve has a single valve spring. The pistons have two

compression rings and an oil control ring.

It is important to ensure the correct piston height so

that the piston does not contact the cylinder head.

The correct piston height also ensures the efficient

combustion of fuel which is necessary in order to

conform to requirements for emissions.

The crankshaft for the 403F-15Tengines have four

main bearing journals. The crankshaft for the 404F-

22, and 404F-22Tengines have five main bearing

journals. End play for all the engines is controlled by

the thrust washers that are located on the rear main

bearing. The 403F-15 engine has aluminum bearing

caps on the rear main bearing that act as thrust

washers.

The timing gears are stamped with timing marks in

order to ensure the correct alignment of the gears

during assembly. When the No. 1 piston is at top

center compression stroke, the teeth that are

stamped on the crankshaft gear and the camshaft

gear will be in alignment with the idler gear.

The crankshaft gear turns the idler gear which then

turns the camshaft gear.

The fuel injection pump and the fuel priming pump are

mounted on the cylinder block. Both pumps are

operated by the camshaft lobes.

The fuel injection pump conforms to requirements for

emissions. Adjustments to the fuel injection pump

timing and high idle should only be made by trained

personnel. The fuel injection pumps have mechanical

governors that control the engine rpm.

This document is printed from SPI². Not for RESALE

![]()

KENR9144

5

Systems Operation Section

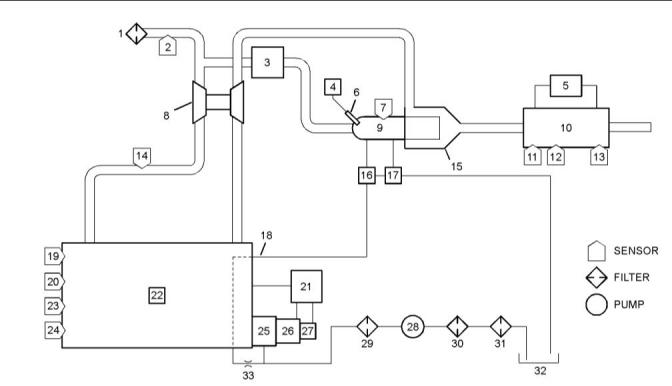

403F-15T

Illustration 1

g03246538

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

6

KENR9144

Systems Operation Section

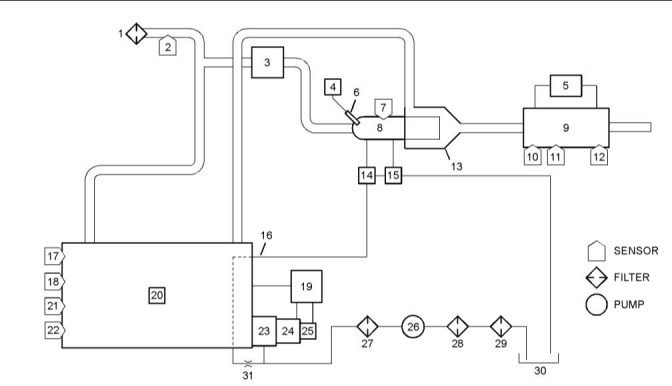

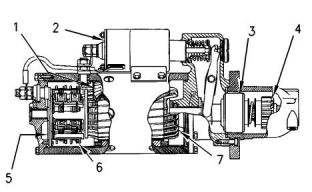

404F-22

Illustration 2

g03246558

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

7

Systems Operation Section

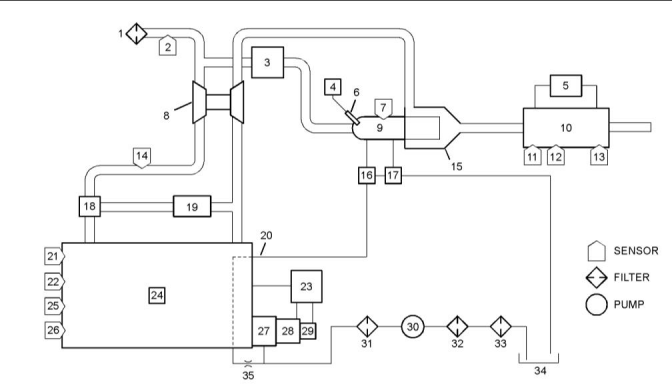

404F-22T

Illustration 3

g03246676

Typical example

(1) Top oil filler

(2) Fan

(3) Side oil filler

(4) Cylinder block drain plug

(5) Oil gauge (Dipstick)

(6) Rear oil drain plug

(7) Oil filter

(8) Electric fuel pump

(9) Secondary fuel filter

This document is printed from SPI². Not for RESALE

![]()

![]()

8

KENR9144

Systems Operation Section

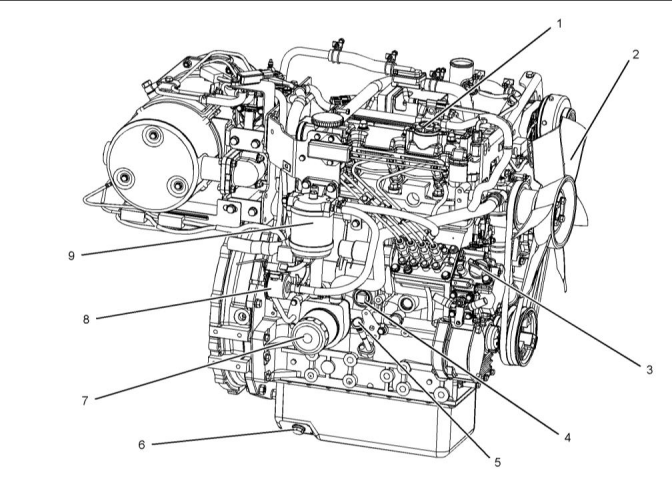

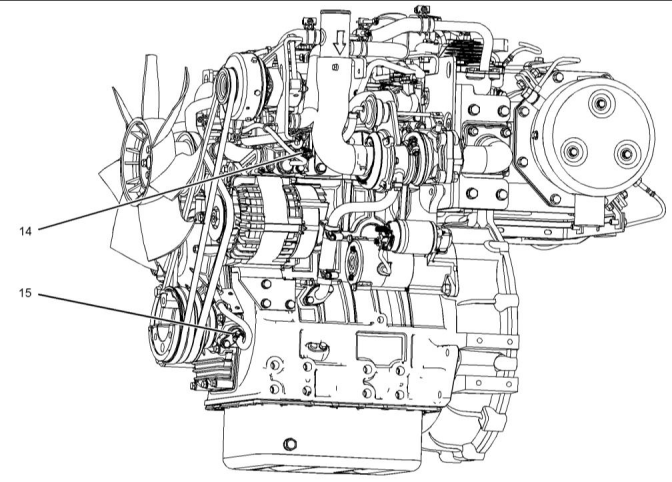

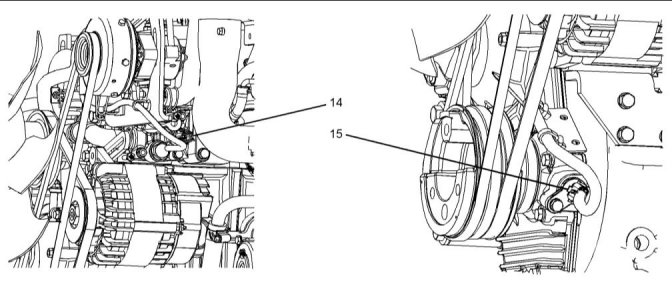

Illustration 4

g03246563

Typical example

(10) Air intake

(14) Flywheel housing

(15) Starting motor

(16) Solenoid for starting motor

(17) Front oil drain plug

(18) NOx reduction system cooler

(19) Coolant outlet

(11) Turbocharger

(12) Aftertreatment system

(13) Flywheel

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

9

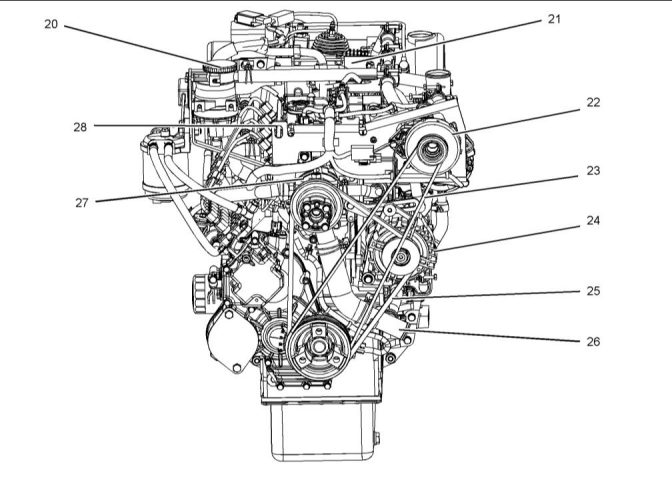

Systems Operation Section

Illustration 5

g03249056

Typical example

(20) Engine crankcase breather

(21) Rear lifting eye bracket

(22) Air pump

(23) Air pump drive belt

(24) Alternator

(25) Fan and alternator drive belt

(26) Coolant intake

(27) Water pump

(28) Front lifting eye

This document is printed from SPI². Not for RESALE

![]()

![]()

10

KENR9144

Systems Operation Section

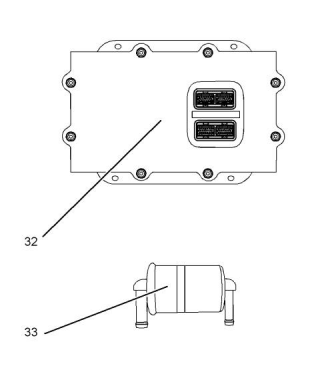

Loose Components for the Engine

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

ARD Air Pump – The ARD air pump provides a

pressurized supply of air to the ARD combustion

chamber

ARD Air Pump Relay – The ARD air pump relay

controls the operation of the ARD air pump.

ARD Glow Plug – The ARD glow plug ignites the fuel

that is injected into the ARD combustion chamber.

ARD Glow Plug Relay – The ARD glow plug relay is

controlled by the ECM in order to provide power to

the ARD glow plug in the ARD combustion chamber.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top center position in the normal direction of rotation.

Boost Pressure – The difference between the

turbocharger outlet pressure and atmospheric

pressure is commonly referred to as boost pressure.

The sensor for the intake manifold air pressure

measures the amount of boost.

Breakout Harness – The breakout harness is a test

harness that is designed to connect into the engine

harness. This connection allows a normal circuit

operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Illustration 6

g03271819

Typical example

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circuit is typically used as a test circuit.

(32) Electronic Control Unit (ECM)

(33) In line fuel filter

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Data Link is a serial communications port

that is used for communication with other

microprocessor-based devices.

i05181776

Glossary of Electronic Control

Terms

Clean Emissions Module (CEM) – Refer to

“Aftertreatment” .

Active Diagnostic Code – An active diagnostic code

alerts the operator or the service technician that an

electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Code – Refer to “Diagnostic Code” or “Event Code”

.

Cold Mode – Cold mode is a mode for cold starting

and for cold engine operation. This mode is used for

engine protection, reduced smoke emissions, and

faster warm-up time.

Aftertreatment – Aftertreatment is a system that is

used to remove pollutants from exhaust gases. The

system consists of the regeneration system, a diesel

oxidation catalyst, and a diesel particulate filter.

Communication Adapter Tool – The communication

adapter provides a communication link between the

ECM and the Electronic Service Tool.

AftertreatmentRegeneration Device (ARD) – This

item is sometimes referred to as the regeneration

system. The ARD is a device that intermittently raises

the temperature of the exhaust gases in order to

regenerate the diesel particulate filter.

Component Identifier (CID) – The CID is a number

that identifies the specific component of the electronic

control system that has experienced a diagnostic

code.

Air-To-Air Aftercooler – An air-to-air aftercooler is a

device that is used on turbocharged engines in order

to cool inlet air that has undergone compression. The

inlet air is cooled after the inlet air passes through the

turbocharger. The inlet air is passed through an

aftercooler (heat exchanger) that uses ambient air for

cooling. The inlet air that has been cooled advances

to the inlet manifold.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

for engine monitoring.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR9144

11

Systems Operation Section

Data Link – The Data Link is a serial communication

port that is used for communication with other

microprocessor-based devices.

operation under all conditions. The electronic engine

control also controls the engine operation under all

conditions.

Derate – Certain engine conditions will generate

event codes. Also, engine derates may be applied.

The map for the engine derate is programmed into

the ECM software. The derate can be one or more of

three types: reduction of rated power, reduction of

rated engine speed and reduction of rated machine

speed for OEM products.

Engine Control Module (ECM) – The ECM is the

control computer of the engine. The ECM provides

power to the electronics. The ECM monitors data that

is input from the sensors of the engine. The ECM acts

as a governor in order to control the speed and the

power of the engine.

Electronic Service Tool – The electronic service tool

allows a computer (PC) to communicate with the

ECM.

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed sensor, and

other sensors in order to determine the desired

engine speed.

Engine Monitoring – Engine Monitoring is the part of

the electronic engine control that monitors the

sensors. This also warns the operator of detected

problems.

Diagnostic Trouble Code – A diagnostic trouble

code is sometimes referred to as a fault code. These

codes indicate an electronic system malfunction.

Engine Oil Pressure Switch – The engine oil

pressure switch provides a warning of low engine oil

pressure. The switch controls a warning lamp at the

operator position.

Diagnostic Lamp – A diagnostic lamp is sometimes

called the check engine lamp. The diagnostic lamp is

used to warn the operator of the presence of an

active diagnostic code. The lamp may not be included

in all applications.

Engine Speed Sensor – An engine speed sensor is

a Hall effect sensor that provides a digital signal to

the ECM. The ECM interprets this signal as the

engine speed. Two sensors are used to provide the

speed signals to the ECM. The primary sensor and

the secondary sensor are associated with the

crankshaft.

Diesel Oxidation Catalyst – The Diesel Oxidation

Catalyst is also known as the (DOC). The DOC is a

device in the exhaust system that oxidizes certain

elements in the exhaust gases. These elements can

include carbon monoxide (CO), hydrocarbons and the

soluble organic fraction (SOF) of particulate matter.

Event Code – An event code may be activated in

order to indicate an abnormal engine operating

condition. These codes usually indicate a mechanical

problem instead of an electrical system problem.

Diesel Particulate Filter – The Diesel Particulate

Filter (DPF) filters particulates from the exhaust

gases. When the particulates have built up on the

internal surfaces of the DPF, the temperature of the

exhaust gas is raised by the Aftertreatment

Regeneration Device (ARD) in order to burn off the

particulates. This regeneration process prevents the

DPF from becoming blocked. The regeneration

process therefore allows the DPF to continue to

operate efficiently.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that is associated with the

component. The FMI has been adopted from the SAE

practice of J1587 diagnostics. The FMI follows the

parameter identifier (PID) in the descriptions of the

fault code. The descriptions of the FMIs that are used

on these engines are in the following list:

0 – The data is valid but the data is above the normal

operational range.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

1 – The data is valid but the data is below the normal

operational range.

3 – The voltage is above normal or the voltage is

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power from the ECM.

shorted high.

4 – The voltage is below normal or the voltage is

shorted low.

Digital Sensor Supply – The power supply for the

digital sensors is provided by the ECM.

6 – The current is above normal or the circuit is

grounded.

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

7 – The mechanical system is not responding

properly.

DT, DT Connector, or Deutsch DT – This is a type

of connector that is used on the engines. The

connectors are manufactured by Deutsch .

8 – There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

10 – There is an abnormal rate of change.

11 – The failure mode is not identifiable.

12 – The device or the component is damaged.

Duty Cycle – Refer to “Pulse Width Modulation” .

Electronic Engine Control – The electronic engine

control is a complete electronic system. The

electronic engine control monitors the engine

This document is printed from SPI². Not for RESALE

![]()

12

KENR9144

Systems Operation Section

13 – The device requires calibration.

Inlet Manifold Air Temperature Sensor – The inlet

manifold air temperature sensor detects the air

temperature in the inlet manifold.

14 – There is a special instruction for the device.

15 – The signal from the device is high (least severe)

.

Inlet Manifold Pressure Sensor – The Inlet Manifold

Pressure Sensor measures the pressure in the inlet

manifold. The pressure in the inlet manifold may be

different to the pressure outside the engine

(atmospheric pressure). The difference in pressure

may be caused by an increase in air pressure by a

turbocharger.

16 – The signal from the device is high (moderate

severity) .

31 – The device has failed and the engine has shut

down.

Integrated Electronic Controls – The engine is

designed with the electronic controls as a necessary

part of the system. The engine will not operate

without the electronic controls.

Flash File – This file is software that is inside the

ECM. The file contains all the instructions (software)

for the ECM and the file contains the performance

maps for a specific engine. The file may be

reprogrammed through flash programming.

J1939 CAN Data Link – This data link is a SAE

standard diagnostic communications data link that is

used to communicate between the ECM and other

electronic devices.

Flash Programming – Flash programming is the

method of programming or updating an ECM with an

electronic service tool over the data link instead of

replacing components.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are an indicator of possible causes for

intermittent problems. Refer to the term “Diagnostic

Code” for more information.

Fuel Injection Pump – This is a device that supplies

fuel under pressure to the fuel injectors and controls

the injection timing.

Fuel Ratio Control (FRC) – The FRC is a limit that is

based on the control of the ratio of the fuel to air. The

FRC is used for purposes of emission control. When

the ECM senses a lower inlet manifold air pressure

(less air into the cylinder), the FRC decreases the

FRC Limit (less fuel into the cylinder).

NOx Reduction System – The NOx Reduction

System recycles a portion of the exhaust gases back

into the inlet air in order to reduce the formation of

nitrous oxide (NOx) in the combustion process. The

recycled exhaust gas passes through a cooler before

being introduced into the inlet air.

Full Load Setting (FLS) – The FLS is the number

that represents the fuel system adjustment. This

adjustment is made at the factory in order to fine-tune

the fuel system. The correct value for this parameter

is stamped on the engine information ratings plate.

This parameter must be programmed.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. This is the manufacturer of

the application that uses the engine.

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an electrical wire or

a connection that is broken. When this condition

exists, the signal or the supply voltage can no longer

reach the intended destination.

Full Torque Setting (FTS) – The FTS is the

parameter that represents the adjustment for the

engine torque. This adjustment is made at the factory

in order to fine-tune the fuel system. This adjustment

is made with the FLS. This parameter must be

programmed.

Parameter – A parameter is a value or a limit that is

programmable. This helps determine specific

characteristics or behaviors of the engine.

Glow Plug – The glow plug is an optional starting aid

for cold conditions. One glow plug is installed in each

combustion chamber in order to improve the ability of

the engine to start. The ECM uses information from

the engine sensors such as the engine temperature

to determine when the glow plug relay must provide

power to each glow plug. Each of the glow plugs then

provides a very hot surface in the combustion

chamber in order to vaporize the mixture of air and

fuel. This improves ignition during the compression

stroke of the cylinder.

Password – A password is a group of numeric

characters or a group of alphanumeric characters that

is designed to restrict access to parameters.

Power Cycling – Power cycling refers to the action of

cycling the keyswitch from any position to the OFF

position, and to the START/RUN position.

Programmable Software – The software is

programmed into the ECM. The software contains all

the instructions (software) for the ECM and the

software contains the performance maps for a

specific engine. The software may be reprogrammed

through flash programming.

Glow Plug Relay – The glow plug relay is controlled

by the ECM in order to provide high current to the

glow plugs that are used in the starting aid system.

Primary Speed Sensor – This sensor determines

the position of the crankshaft during engine operation.

If the primary speed sensor fails during engine

operation, the secondary speed sensor is used to

provide the signal.

Harness – The harness is the bundle of wiring (loom)

that connects all components of the electronic

system.

Hertz (Hz) – Hertz is the unit of frequency in cycles

per second.

This document is printed from SPI². Not for RESALE

![]()

KENR9144

13

Systems Operation Section

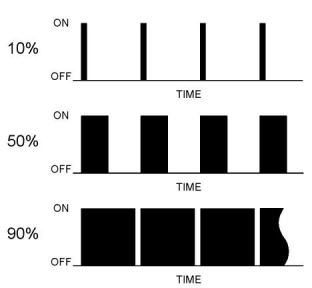

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at fixed intervals. The ratio

of “TIME ON” versus total “TIME OFF” can be

varied. This ratio is also referred to as a duty cycle.

Signal – The signal is a voltage or a waveform that is

used in order to transmit information typically from a

sensor to the ECM.

Supply Voltage – The supply voltage is a continuous

voltage that is supplied to a component in order to

provide the electrical power that is required for the

component to operate. The power may be generated

by the ECM or the power may be battery voltage that

is supplied by the engine wiring.

System Configuration Parameters – System

configuration parameters are parameters that affect

emissions and/or operating characteristics of the

engine.

Tattletale – Certain parameters that affect the

operation of the engine are stored in the ECM. These

parameters can be changed by use of the electronic

service tool. The tattletale logs the number of

changes that have been made to the parameter. The

tattletale is stored in the ECM.

“T” Harness – This harness is a test harness that is

designed to permit normal circuit operation and the

measurement of the voltage simultaneously.

Typically, the harness is inserted between the two

ends of a connector.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Illustration 7

g01858875

Rated Fuel Limit – This is a limit that is based on the

power rating of the engine and on the engine rpm.

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a specific engine model. These limits are in

the flash file and these limits cannot be changed.

Throttle Position Sensor – The throttle position

sensor is an electronic sensor that is usually

connected to an accelerator pedal or a hand lever.

This sensor sends a signal to the ECM that is used to

calculate desired engine speed.

Top Center Position – The top center position refers

to the crankshaft position when the engine piston

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to reach this point.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

Relay – A relay is an electromechanical switch. A

flow of electricity in one circuit is used to control the

flow of electricity in another circuit. A small current or

voltage is applied to a relay in order to switch a much

larger current or voltage.

Wait To Start Lamp – This is a lamp that is included

in the cold starting aid circuit in order to indicate when

the wait to start period is active. The lamp will go off

when the engine is ready to be started. The glow

plugs may not have deactivated at this point in time.

Secondary Speed Sensor – This sensor determines

the position of the camshaft during engine operation.

If the primary speed sensor fails during engine

operation, the secondary speed sensor is used to

provide the signal.

Wastegate – This is a device in a turbocharged

engine that controls the maximum boost pressure that

is provided to the inlet manifold.

Sensor – A sensor is a device that is used to detect

the current value of pressure or temperature, or

mechanical movement. The information that is

detected is converted into an electrical signal.

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit is

a wire which rubs against a vehicle frame and this

rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and a short

circuit results.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

14

KENR9144

Systems Operation Section

i05173593

Electronic Control System

Components

The engine has an Electronic Control Module (ECM).

There are also a number of engine sensors. The

ECM controls the engine operating parameters

through the software within the ECM and the inputs

from the various sensors. The software contains

parameters that control the engine operation. The

parameters include all of the operating maps and

customer-selected parameters.

The electronic control system has the following

components:

• ECM

• Pressure sensors

• Temperature sensors

• Crankshaft speed sensors

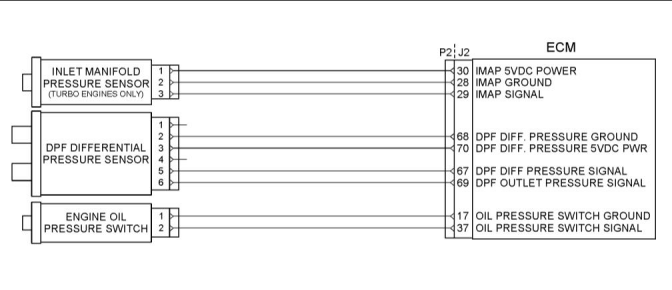

Illustration 9 is a block diagram of the control system

on a normally aspirated engine. Illustrations 8 and 10

are block diagrams of the control system on

turbocharged engines.

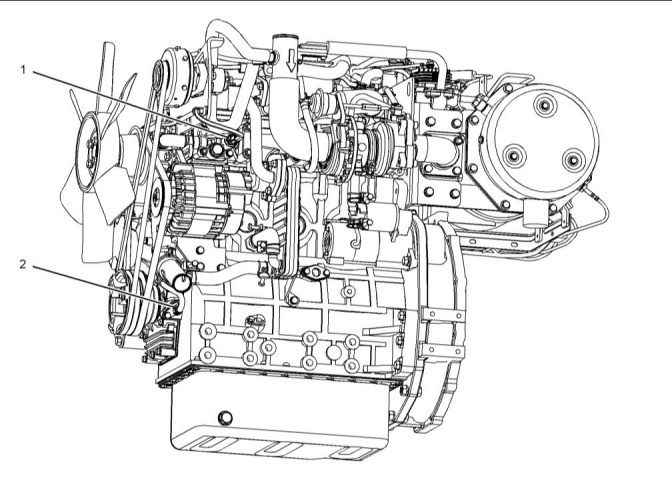

Block diagram for the 403F-15T engine

Illustration 8

g03339508

Typical example

(1) Air cleaner

(2) Air inlet temperaturesensor

(3) Aftertreatment Regeneration Device

(ARD) air pump

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

15

Systems Operation Section

(4) ARD glow plug relay

(5) Diesel Particulate Filter (DPF) differential

pressure sensor

(6) ARD glow plug

(7) ARD combustion chamber temperature

sensor

(13) DPF outlet temperature sensor

(14) Boost pressure sensor

(15) ARD body

(16) ARD injector No.1

(17) ARD injector No.2

(18) Injector leak-off return line

(19) Coolant temperature sensor

(20) Primary speed sensor

(21) Electronic Control Module (ECM)

(22) Engine

(25) Fuel injection pump and fuel control

rack

(26) Fuel rack actuator

(27) Fuel rack position sensor

(28) Fuel transfer pump

(29) Secondary fuel filter

(30) Primary fuel filter

(31) In line fuel filter

(8) Turbocharger

(9) ARD combustion chamber

(10) Diesel Oxidation Catalyst (DOC) and

DPF

(32) Fuel tank

(33) Fuel restrictor

(11) DOC inlet temperature sensor

(12) DPF inlet temperaturesensor

(23) Oil pressure switch

(24) Engine glow plug relay

This document is printed from SPI². Not for RESALE

![]()

16

KENR9144

Systems Operation Section

Block diagram for the 404F-22 engine

Illustration 9

g03339507

Typical example

(1) Air cleaner

(10) DOC inlet temperature sensor

(22) Engine glow plug relay

(2) Air inlet temperaturesensor

(3) Aftertreatment Regeneration Device

(ARD) air pump

(4) ARD glow plug relay

(5) Diesel Particulate Filter (DPF) differential

pressure sensor

(6) ARD glow plug

(7) ARD combustion chamber temperature

sensor

(11) DPF inlet temperature sensor

(12) DPF outlet temperature sensor

(13) ARD body

(14) ARD injector No.1

(15) ARD injector No.2

(16) Injector leak-off return line

(17) Coolant temperature sensor

(18) Primary speed sensor

(19) Electronic Control Module (ECM)

(20) Engine

(23) Fuel injection pump and fuel control

rack

(24) Fuel rack actuator

(25) Fuel rack position sensor

(26) Fuel transfer pump

(27) Secondary fuel filter

(28) Primary fuel filter

(29) In line fuel filter

(30) Fuel tank

(31) Fuel restrictor

(8) ARD combustion chamber

(9) Diesel Oxidation Catalyst (DOC) and

DPF

(21) Oil pressure switch

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

17

Systems Operation Section

Block diagram for the 404F-22T engine

Illustration 10

g03339510

Typical example

(1) Air cleaner

(12) DPF inlet temperature sensor

(26) Engine glow plug relay

(2) Air inlet temperaturesensor

(3) Aftertreatment Regeneration Device

(ARD) air pump

(4) ARD glow plug relay

(5) Diesel Particulate Filter (DPF) differential

pressure sensor

(6) ARD glow plug

(7) ARD combustion chamber temperature

sensor

(13) DPF outlet temperature sensor

(14) Boost pressure sensor

(15) ARD body

(16) ARD injector No.1

(17) ARD injector No.2

(27) Fuel injection pump and fuel control

rack

(28) Fuel rack actuator

(29) Fuel rack position sensor

(30) Fuel transfer pump

(31) Secondary fuel filter

(32) Primary fuel filter

(33) In line fuel filter

(18) Valve for the NOx Reduction System

(NRS)

(19) Exhaust gas cooler (NRS)

(20) Injector leak-off return line

(21) Coolant temperature sensor

(22) Primary speed sensor

(23) Electronic Control Module (ECM)

(24) Engine

(34) Fuel tank

(35) Fuel restrictor

(8) Turbocharger

(9) ARD combustion chamber

(10) Diesel Oxidation Catalyst (DOC) and

DPF

(11) DOC inlet temperature sensor

(25) Oil pressure switch

Sensor Locations for the Engine

The illustrations in this section show the typical

locations of the sensors for the industrial engine.

Specific engines may appear different from the

illustration due to differences in applications.

Note: In the following illustrations, some components

have been removed in order to improve visibility.

This document is printed from SPI². Not for RESALE

![]()

![]()

18

KENR9144

Systems Operation Section

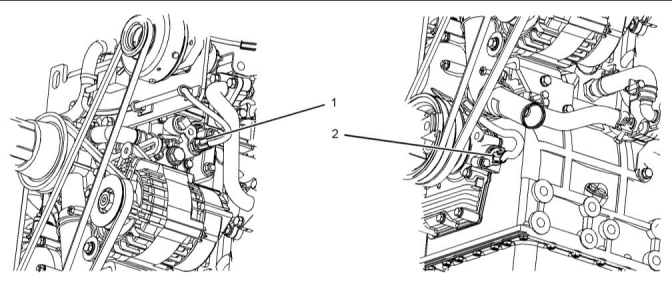

Illustration 11

g03339512

Sensor locations on the left side of the 403F-15T engine

(1) Coolant temperature sensor

(2) Primary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

19

Systems Operation Section

Illustration 12

g03339513

Close up views of sensor locations on the left side of the 403F-15T engine

(1) Coolant temperature sensor

(2) Primary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

20

KENR9144

Systems Operation Section

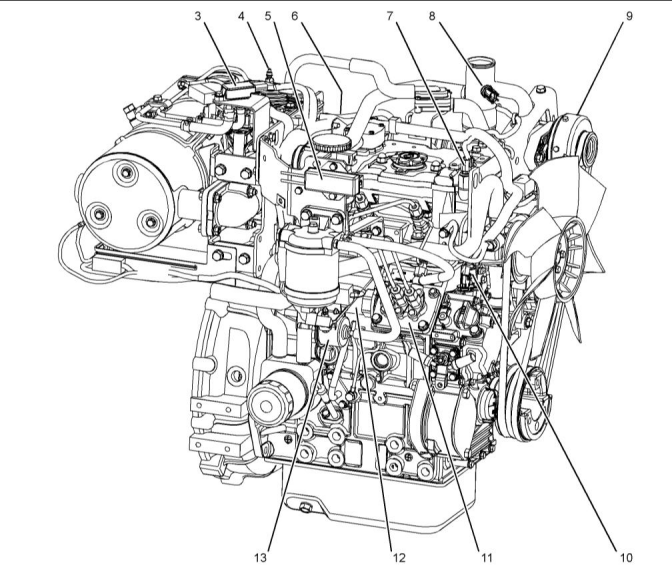

Illustration 13

g03339514

Sensor and component locations on the top and right side of the 403F-15T engine

(3) DPF differential pressure sensor

(4) ARD glow plug

(5) ARD glow plug resistor

(7) Oil pressure switch

(8) Air inlet temperaturesensor

(9) ARD air pump

(11) Fuel injection pump and fuel control rack

(12) Fuel rack solenoid and position sensor

(13) Electric fuel priming pump

(6) Boost pressure sensor (if equipped)

(10) Secondary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

21

Systems Operation Section

Illustration 14

g03339515

Close-up views of sensor and component locations on the top and right side of the 403F-15T engine

(3) DPF differential pressure sensor

(4) ARD glow plug

(5) ARD glow plug resistor

(7) Oil pressure switch

(8) Air inlet temperaturesensor

(9) ARD air pump

(11) Fuel pump and fuel rack

(12) Fuel rack solenoid and position sensor

(13) Electric fuel lift pump

(6) Boost pressure sensor (if equipped)

(10) Secondary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

22

KENR9144

Systems Operation Section

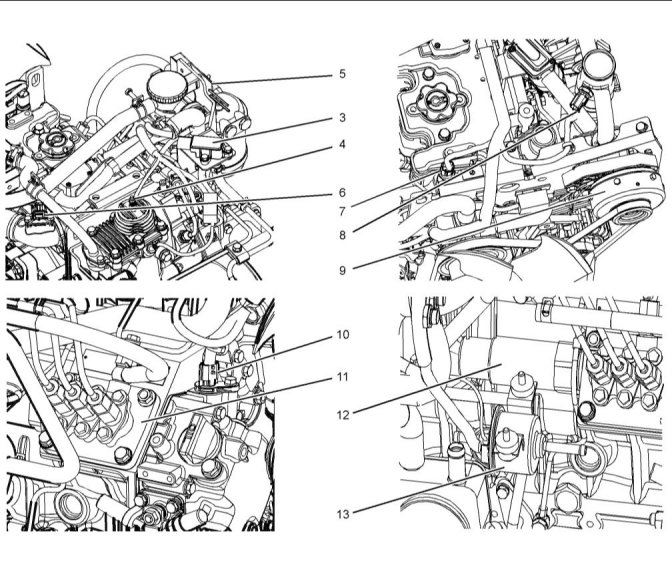

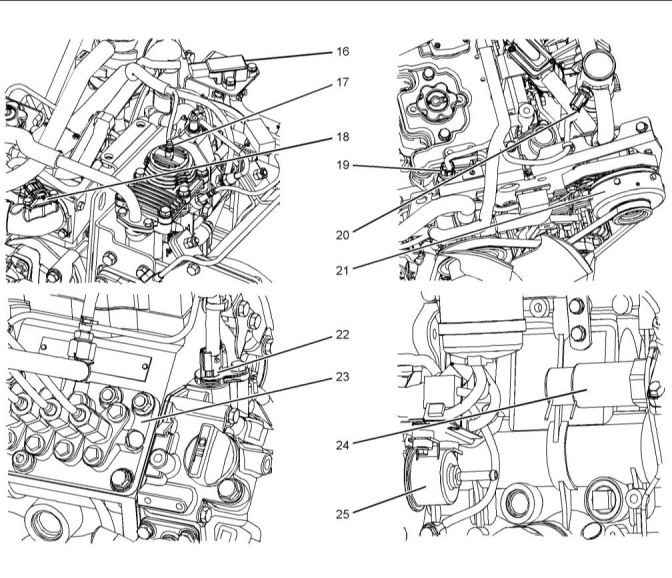

Illustration 15

g03339516

Typical sensor locations on the left side of the 404F-22 engines

(14) Coolant temperaturesensor

(15) Primary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

23

Systems Operation Section

Illustration 16

g03339517

Close-up views of typical sensor locations on the left side of the 404F-22 engines

(14) Coolant temperaturesensor

(15) Primary speed sensor

This document is printed from SPI². Not for RESALE

![]()

![]()

24

KENR9144

Systems Operation Section

Illustration 17

g03339518

Typical sensor locations on the right side and top of the 404, F-22 engines

(16) DPF differential pressure sensor

(17) ARD glow plug

(20) Air inlet temperaturesensor

(21) ARD air pump

(23) Fuel injection pump and fuel control

rack

(18) Boost pressure sensor (if equipped)

(19) Oil pressure switch

(22) Secondary speed sensor

(24) Fuel rack solenoid and position sensor

(25) Electric fuel priming pump

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

25

Systems Operation Section

Illustration 18

g03339520

Close-up views of typical sensor locations on the right side and top of the 404F-22 engines

(16) DPF differential pressure sensor

(17) ARD glow plug

(20) Air inlet temperaturesensor

(21) ARD air pump

(23) Fuel injection pump and fuel control

rack

(18) Boost pressure sensor (if equipped)

(19) Oil pressure switch

(22) Secondary speed sensor

(24) Fuel rack solenoid and position sensor

(25) Electric fuel priming pump

This document is printed from SPI². Not for RESALE

![]()

![]()

26

KENR9144

Systems Operation Section

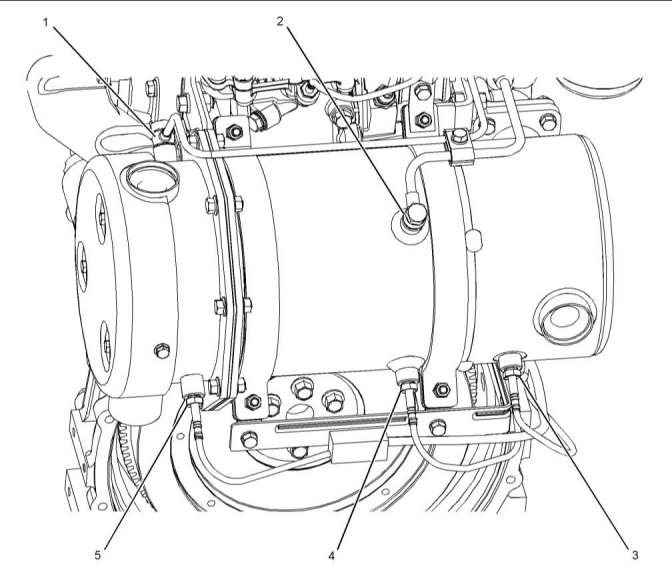

Sensor Locations for the Clean Emissions Module

Illustration 19

g03339521

Sensors and components on a typical Clean Emissions Module (CEM)

(1) DPF outlet pressure connection

(2) DPF intake pressure connection

(3) DOC intake temperaturesensor

(4) DPF intake temperaturesensor

(5) DPF outlet temperaturesensor

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

27

Systems Operation Section

ECM

Engine Speed

The ECM has software that compares the desired

engine speed to the actual engine speed. The actual

engine speed is determined through the crankshaft

speed sensor. If the desired engine speed is greater

than the actual engine speed, the ECM will instruct

the fuel injection pump to supply more fuel to the fuel

injectors in order to increase engine speed.

Fuel Injection

The programmable software inside the ECM sets

certain limits on the amount of fuel that can be

provided to the fuel injectors.

The ECM controls the following characteristics:

• Operation of the NOx reduction system (if

equipped)

• Regeneration

Diagnostic Codes

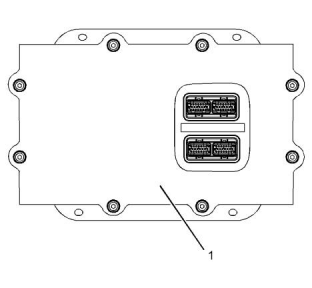

Illustration 20

g03322430

When the ECM detects an electronic system

problem, the ECM generates a diagnostic code. Also,

the ECM logs the diagnostic code in order to indicate

the time of the problem's occurrence. The ECM also

logs the number of occurrences of the problem.

Diagnostic codes are provided in order to indicate

that the ECM has detected an electrical problem or

an electronic problem with the engine control system.

In some cases, the engine performance can be

affected when the condition that is causing the code

exists.

Typical example

The Electronic Control Module (ECM) (1) functions as

a computer for the fuel system.

The electronic system consists of the ECM, the

engine sensors, and inputs from the application. The

ECM is the computer. The flash file is the software for

the computer. The flash file contains the operating

maps. The operating maps define the following

characteristics of the engine:

If the operator indicates that a performance problem

occurs, the diagnostic code may indicate the cause of

the problem. Use a laptop computer to access the

diagnostic codes. The problem should then be

corrected.

• Engine rating

• Torque curves

• High and low idle speed (rpm)

• Emissions

Event Codes

The ECM has an excellent record of reliability. Any

problems in the system are most likely to be the

connectors and the wiring harness. The ECM should

be the last item in troubleshooting the engine.

Event Codes are used to indicate that the ECM has

detected an abnormal engine operating condition.

The ECM will log the occurrence of the event code.

This does not indicate an electrical malfunction or an

electronic malfunction. If the temperature of the

coolant in the engine is higher than the permitted

limit, then the ECM will detect the condition. The ECM

will then log an event code for the condition.

The programmable software contains all the fuel

setting information. The information determines the

engine performance.

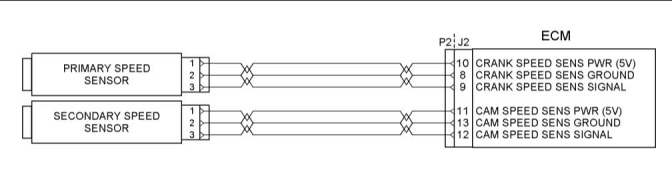

Speed Sensors

Flash programming is the method of programming or

updating the programmable software. Refer to

Troubleshooting, “Flash Programming” for the

instructions on the flash programming of the

programmable software.

The engine has two speed sensors installed to

measure crankshaft speed.

The ECM is sealed and the ECM needs no routine

adjustment or maintenance.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

28

KENR9144

Systems Operation Section

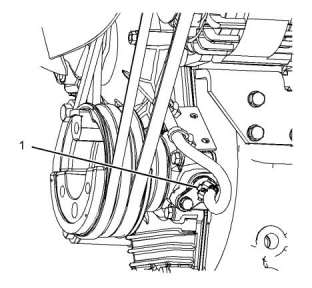

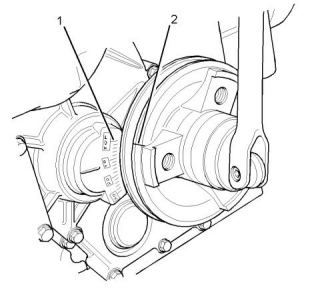

Illustration 21

g03323793

Typical example

The primary speed sensor (1) is located on the left-

hand side of the engine towards the bottom of the

front housing.

The primary speed sensor generates a signal by

detecting the movement of the crankshaft. The signal

that is generated by the speed sensor is transmitted

to the ECM.

The ECM uses the signal from the speed sensor to

determine the engine speed.

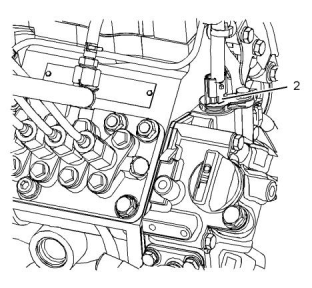

Illustration 22

g03323794

Typical example

The secondary speed sensor (2) is located on the

right-hand side of the engine towards the top of the

front housing.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

29

Systems Operation Section

Illustration 23

g03323790

Typical example

This document is printed from SPI². Not for RESALE

![]()

![]()

30

KENR9144

Systems Operation Section

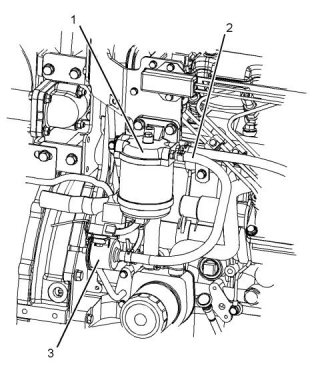

Pressure Sensors and Switches

Illustration 24

g03323797

Typical example

The boost pressure sensor is an active sensor.

The boost pressure sensor provides the ECM with a

measurement of inlet manifold pressure.

The operating range of the boost pressure sensor is

39 to 400 kPa (6 to 58 psi).

The engine oil pressure switch provides the ECM with

a measurement of engine oil pressure. The ECM can

warn the operator of possible conditions that can

damage the engine. This includes the detection of an

oil filter that is blocked.

The engine oil pressure switch is operated when a

pressure of 50 to 80 kPa (7 to 12 psi) is detected.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

31

Systems Operation Section

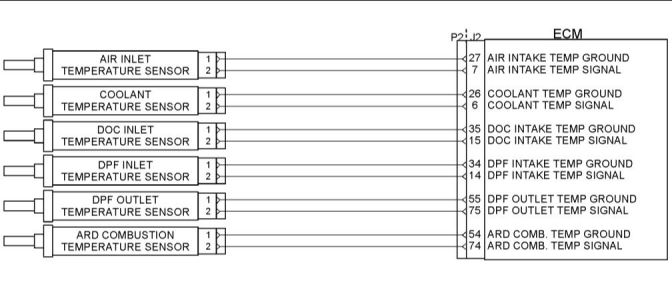

Temperature Sensors

Illustration 25

g03323798

Typical example

The air inlet temperature sensor and the coolant

temperature sensor are passive sensors. Each

sensor provides a temperature input to the ECM. The

ECM controls following operations:

• Fuel delivery

The operating range for the sensors .....−40° to 130°C

(−40° to 234°F)

The sensors are also used for engine monitoring.

i04904125

Fuel System

General Operation of the Fuel

System

Refer to Systems Operation, Testing, and Adjusting,

“General Information” for locations of the components

for the fuel system.

This document is printed from SPI². Not for RESALE

![]()

![]()

32

KENR9144

Systems Operation Section

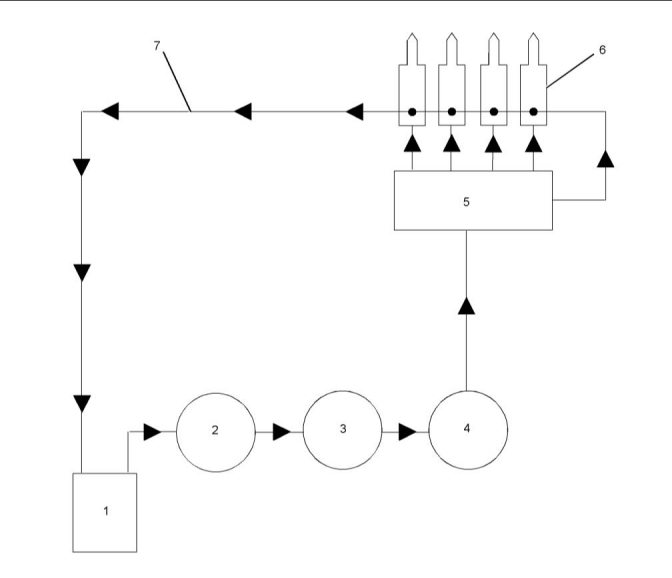

Illustration 26

g03059777

Typical example

(1) Fuel tank

(2) Primary fuel filter/water separator

(3) Fuel transfer pump

(4) Secondary fuel filter

(5) Fuel injection pump

(6) Fuel injectors

(7) Fuel return line from the fuel injection

pump and the fuel injectors to the fuel

tank

When the engine is cranking, the fuel is pulled from

the fuel tank (1) by the electric fuel transfer pump (3).

A primary fuel filter/water separator (2) is installed

between the fuel tank (1) and the fuel transfer pump

(3). The primary fuel filter/water separator has an

inline style filter. Refer to Operation and Maintenance

Manual for more information on the service of the

primary fuel filter/water separator. The fuel transfer

pump forces the fuel through the secondary fuel filter

(4) to the fuel injection pump (5).

The fuel injection pump sends fuel at high pressure to

each fuel injector nozzle (6). The fuel injector nozzle

sprays fuel into a precombustion chamber which

slows the rate of combustion in the cylinder. The

following items will result from reducing the rate of

fuel combustion: prevention of engine knock,

reduction of noise and reduction of emissions.

The secondary fuel filter (4) can also function as a

water separator. The secondary fuel filter can be

drained through a valve that is located at the bottom

of the filter housing.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

33

Systems Operation Section

Governor

The fuel rack is connected to the linkage, which

controls the fuel injection pump. This linkage is

located in the front housing.

These engines have a mechanical governor in order

to control engine speed. The governor operates for all

engine rpm. The governor weight assembly is

installed on the front of the gear of the camshaft. The

other components of the governor are installed in the

front housing.

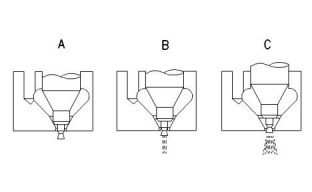

Illustration 27

g00468241

Phases of operation of the fuel injection nozzle

(A) Closed valve

(B) Open valve

(C) Fully open valve

The fuel injection nozzle injects fuel into the

precombustion chamber at different angles during

two phases. Most of the fuel is injected when the

valve is fully open (C). This process is called indirect

fuel injection. The results are more even combustion

and complete combustion of the fuel at a reduced

temperature. Improved fuel combustion will increase

power output while reducing emissions and reducing

fuel consumption.

Excess fuel from the fuel injection nozzles and the

fuel injection pump flows through fuel return line (7),

through the injectors in the ARD and back to the fuel

tank (1). The excess fuel aids the cooling of the fuel

injection nozzles. Also, the fuel return line removes

any air that is trapped in the fuel injection nozzles and

the fuel injection pump.

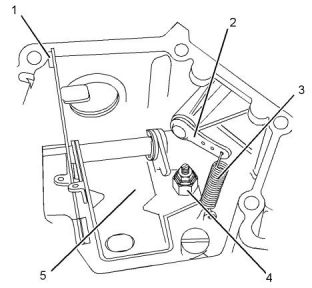

Illustration 28

g03335322

Typical example of the governor control mechanism

in the front housing

(1) Connection for the linkage to the fuel injection pump

(2) Control lever

(3) Lever return spring

(4) Governor adjustment screw

(5) Arm

The fuel injection pump needs fuel for lubrication. If

the precision parts of the pump are not adequately

lubricated, the components may be easily damaged.

The engine must not be started until the fuel injection

pump is full of fuel that is free of air.

The movement of the governor weight assembly is

transferred to the fuel rack on the fuel injection pump

by the control lever (2), the governor lever (5), and the

linkage to the fuel injection pump. The governor main

spring (3) connects the governor lever to the control

lever. The governor main spring controls the

movement of the governor weight assembly on the

camshaft. When the angle of the control lever

changes, the tension on the governor main spring

changes. This action controls the linkage to the fuel

rack on the fuel injection pump, which controls the

engine rpm.

The system must be primed by the electric fuel

priming pump when any part of the system is drained

of fuel. The following list contains examples of both

service and repairs when you must prime the system:

• The fuel filter is changed.

• The low-pressure fuel line is removed.

• The fuel injection pump is removed.

• The fuel injection nozzles are removed.

• The fuel tank is drained.

The maximum fuel adjustment screw is mounted in

the front housing. The maximum fuel adjustment

screw is set to the full fuel position. This limits the

maximum fuel that can be injected into the engine in

case the fuel rack solenoid and position sensor is in

fully open position. The fuel rack solenoid and

position sensor controls the fuel delivery by limiting

the mechanical fuel allowance.

• A leak exists in the low-pressure side of the fuel

system.

In order to release air from the fuel injection pump

and the fuel injection nozzles, refer to Systems

Operation, Testing, and Adjusting, “Fuel System -

Prime”.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

34

KENR9144

Systems Operation Section

Adjustments to the pump timing should only be made

by personnel that have had the correct training. The

timing for the fuel injection pump should only change

if the camshaft or the cylinder block are replaced. The

fuel injection pump timing should not change if the

fuel injection pump is reinstalled with a shim that is

the same size.

The fuel injection pump is a pressurized system that

is totally enclosed. The pump sends the correct

amount of fuel under high pressure at the correct time

through the fuel injection nozzles to the individual

cylinders. The fuel injection occurs near the end of

the compression stroke. The fuel injection pump

regulates the amount of fuel that is delivered to the

fuel injection nozzles. This action controls the engine

rpm by the governor setting or the position of the

throttle control.

The fuel rack automatically returns to the excess fuel

position when the engine is stopped. The excess fuel

position aids the cold starting of the engine.

The camshaft is driven by the idler gear in the front

gear case. Lobes on the camshaft cause the pushrod

for each cylinder to reciprocate. The reciprocating

motion first draws the fuel. The reciprocating motion

then pressurizes the fuel. A fuel delivery valve (2) for

each cylinder acts as a check valve in order to

A spring connects the linkage to the fuel injection

pump and mechanical stop control (2). When the

engine is first started, the spring automatically

increases the fuel flow to the cylinders.

Fuel Injection Pump

prevent a loss of pressure to the fuel injection nozzle.

The correct operation of the fuel injection pump

requires the pump to be completely full of fuel and

empty of air. When vent screw (5) is loosened, air can

escape from the fuel injection pump.

The fuel injection pump will lubricate the components

during operation.

Fuel Injection Nozzles

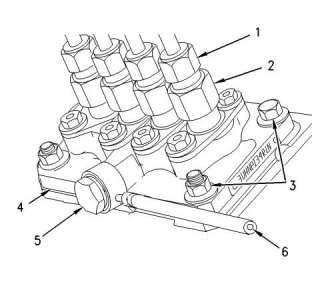

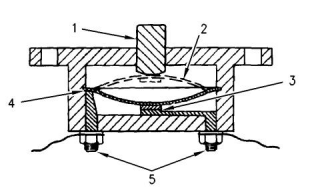

Illustration 29

g00746909

Fuel injection pump (typical example)

(1) Fuel line to the fuel injection nozzles

(2) Fuel delivery valve

(3) Nuts and bolts for mounting the fuel injection pump to the

cylinder block

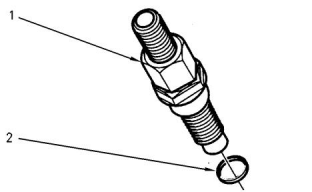

Illustration 30

g00836660

(1) Fuel injection nozzle

(2) Washer

(4) Shim

(5) Vent screw for the fuel injection pump

(6) Fuel flow from the fuel transfer pump

The washer (2) helps to prevent blowby. The washer

also sets the projection of the fuel injection nozzle (1)

into the precombustion chamber. This projection

affects the time that is required for combustion in the

cylinder. If the projection is excessive, engine knock

can occur at high rpm.

The engines have the energized-to-run system for

starting the engine and stopping the engine. The fuel

rack solenoid and position sensor must be energized

in order for fuel to flow to the engine cylinders.

Note: When a fuel injection nozzle (1) is installed in

the cylinder head, a new washer (2) should be

installed.

The fuel injection pump is a cassette type pump. The

cassette type pump contains the following

components: fuel delivery valves, fuel rack and

pushrods. The fuel injection pump is installed directly

into the cylinder block.

The operating pressure of the fuel injection nozzle is

set and tested at the factory. Refer to Specifications,

“Fuel Injection Nozzles” for the pressure settings of

the fuel injection nozzle.

The part number and code letters for the fuel injection

pump are stamped on the front of the pump.

During operation, extra fuel is used as coolant and

lubricant for components of the fuel injection nozzle.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

35

Systems Operation Section

Fuel Transfer Pump

The mixture of air and fuel is compressed in the

cylinder in order to heat the mixture to the

temperature of combustion.

Power to the electric fuel transfer pump is supplied

through a relay when the keyswitch is turned to the

START position. The motor that is located inside the

electric fuel transfer pump will start to spin. The

electric fuel transfer pump then creates a vacuum in

order to force fuel from the fuel tank. Pressure is

created in order to pump the fuel to the fuel injection

pump.

3. Power

The mixture of air and fuel ignites at the top of the

compression stroke. The expansion of gases from

the combustion forces the piston downward. This

force creates the power of the engine.

The outlet valve and the inlet valve operate as check

valves. The valves maintain residual fuel pressure in

the fuel system when the electric fuel transfer pump is

not operating. The valves also prevent fuel from

flowing in the wrong direction.

4. Exhaust

The piston moves upward in order to force the

gases of combustion from the cylinder through the

open exhaust valve.

Glow Plugs

The sequence of the strokes by all of the pistons in all

of the engine cylinders provides constant air flow from

the air inlet system during the engine operation.

Each cylinder has a glow plug in order to aid the cold

starting of the engine. The glow plugs are controlled

by the Electronic Control Module (ECM).

Turbocharger

In cold ambient temperatures, energizing the glow

plugs for a time period will heat the cylinder

sufficiently for easy starting of the engine.

A turbocharger increases the temperature and the

density of the air that is sent to the engine cylinder.

This condition causes a lower temperature of ignition

to develop earlier in the compression stroke. The

compression stroke is also timed in a more accurate

way with the fuel injection. Surplus air lowers the

temperature of combustion. This surplus air also

provides internal cooling.

Refer to Operation and Maintenance Manual, “Cold

Weather Starting” for the correct method of starting

the engine is cold conditions.

i04904204

A turbocharger improves the following aspects of

engine performance:

Air Inlet and Exhaust System

• Power output is increased.

• Engine torque is increased.

• Engine efficiency is increased.

Naturally aspirated engines pull outside air through

an air cleaner directly into the inlet manifold. The air

flows from the inlet manifold to the engine cylinders.

The fuel is mixed with the air in the engine cylinders.

After the fuel combustion occurs in the engine

cylinder, the exhaust gases flow directly to the outside

air through the exhaust manifold and the exhaust

system.

Turbocharged engines pull outside air through an air

cleaner into the air intake of the turbocharger. The

suction is caused by the turbocharger compressor

wheel. Then, the turbocharger compressor wheel

compresses the air. The air flows through the inlet

manifold which directs an even distribution of the air

to each engine cylinder. Air is pulled into the engine

cylinder during the intake stroke of the piston. Then,

the air is mixed with fuel from the fuel injection

nozzles.

Each piston makes four strokes:

1. Intake

Air is drawn into the cylinder through the open inlet

valve. Fuel is sprayed into the engine by the fuel

injection nozzle.

2. Compression

This document is printed from SPI². Not for RESALE

![]()

36

KENR9144

Systems Operation Section

NOx Reduction System (NRS) -

Turbocharged Engines

The NOx Reduction System (NRS) operates with the

transfer of the hot exhaust gas from the exhaust

manifold to the exhaust cooler. The hot exhaust gas

is cooled in the exhaust cooler. The now cooled

exhaust gas passes through the assembly of the

exhaust gas valve to an electronic controlled valve.

The electronically controlled valve is electronically

actuated. The valve is controlled by the Electronic

Control Module (ECM).

The reed valves that are located in the exhaust gas

valve (NRS) have two main functions. The first

function is to prevent the reverse flow of charge air

from the inlet side of the engine to the exhaust side of

the engine. The second function of the reed valve is

to obtain exhaust gas when the peak exhaust

pressure is above the average inlet pressure.

The electronically controlled valve opens to allow the

flow of cooled exhaust gas from the exhaust cooler to

mix with the air flow from the inlet. The mixing of the

cooled exhaust gas and the air flow from the inlet

reduces the oxygen content of the gas mixture. This

results in a lower combustion temperature, so

decreases the production of NOx.

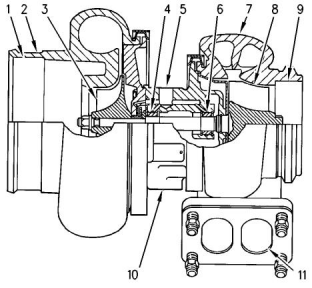

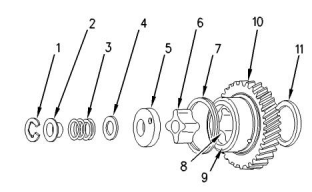

Illustration 31

g00302786

Components of a turbocharger (typical example)

(1) Air intake

(2) Compressor housing

(3) Compressor wheel

(4) Bearing

In some instances, the engine will need to use the

electronically controlled exhaust gas valve for the

NOx Reduction System (NRS) in order to generate

the required flow of exhaust gas.

(5) Oil inlet port

(6) Bearing

(7) Turbine housing

(8) Turbine wheel

(9) Exhaust outlet

(10) Oil outlet port

(11) Exhaust inlet

Cylinder Head And Valves

A turbocharger is installed between the exhaust and

intake manifolds. The turbocharger is driven by

exhaust gases which flow through the exhaust inlet

(11). The energy of the exhaust gas turns the turbine

wheel (8). Then, the exhaust gas flows out of the

turbine housing (7) through the exhaust outlet (9).

Turbine wheel (8) and compressor wheel (3) are

installed on the same shaft. Therefore, turbine wheel

(8) and compressor wheel (3) rotate at the same rpm.

The compressor wheel is enclosed by compressor

housing (2). The compressor wheel compresses the

intake air. The intake air flows into the engine

cylinders through the inlet valves of the cylinders.

The oil from the main gallery of the cylinder block

flows through the oil inlet port (5) in order to lubricate

the turbocharger bearings (4) and (6). The

pressurized oil passes through the bearing housing of

the turbocharger. The oil is returned through the oil

outlet port (10) to the oil pan.

The turbocharger has a wastegate. The wastegate is

controlled by the boost pressure. This allows some of

the exhaust gases to bypass the turbine wheel at

higher engine speeds. The wastegate is a type of

flapper valve that automatically opens at a preset

level of boost pressure in order to allow exhaust gas

to flow around the turbine. The wastegate allows the

design of the turbocharger to be more effective at

lower engine speeds.

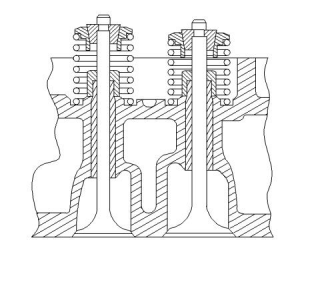

Illustration 32

g00905459

Cross section of the inlet and exhaust valves in the

cylinder head (typical example)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

KENR9144

37

Systems Operation Section

The camshaft gear is driven by the idler gear. The

camshaft gear, the idler gear, and the crankshaft gear

are timed together. When the camshaft turns, the

valve lifters are moved up and down. The pushrods

move the rocker arms. The rocker arms make the

inlet valves and the exhaust valves open and close.

This is in sequence with the firing order of the engine.

The valve springs force the valves back to the closed

position.

Crankcase Breather

NOTICE

The crankcase breather gases are part of the engines

measured emissions output. Any tampering with the

breather system could invalidate the engines emis-

sions compliance.

The engine has a low-pressure closed circuit breather

system installed.

The valve mechanism cover contains a closed

breather assembly. The breather is sealed from the

outside air by a diaphragm. The gases in the valve

cover, which are caused by blowby, pass from the

crankcase to the next component depending on the

type of aspiration system the engine has.

Illustration 33

g00905464

Cylinder head and valves (typical example)

(1) Collets

(2) Valve spring retainer

(3) Valve spring

(4) Valve seal

On the naturally aspirated engine, the crankcase gas

is recirculated internally directly into the inlet

manifold. The inlet connection is a straight out

connection. The inlet connection contains the inlet

temperature sensor and the air supply for the air

compressor.

(5) Valve guide

(6) Cylinder head

(7) Cylinder head gasket

(8) Pushrod

(9) Lifter

(10) Exhaust valve

(11) Inlet valve

On the turbocharged engine, the crankcase gas is

routed through an external pipe from the valve

mechanism cover to the Oil Mist Separator (OMS).

This uses a filter element to separate the oil vapor

from the blow-by gases. The gas exits the filter. The

gas is then piped into the air inlet hose. The gas then

flows into the turbocharger before entering the engine

again through the inlet manifold.

The valves and the rocker shaft assembly control the

flow of air into the cylinders and out of the cylinders

during engine operation. The cylinder head assembly

has two valves for each cylinder. Each valve has one

valve spring (3). The ports for inlet valve (11) and

exhaust valve (10) are on the left side of the cylinder

head.

The valve moves along a steel valve guide (5). The

valve guides can be replaced.

i04901905

The inlet valve and the exhaust valve are opened and

closed by the rotation and movement of the following

components:

Clean Emissions Module

• Crankshaft

• Idler gear

To meet current emissions legislation requirements, a

small amount of certain chemical compounds that are

emitted by the engine must not be allowed to enter

the atmosphere.

• Camshaft

• Valve lifters

• Pushrods

• Rocker arms

• Valve springs

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

38

KENR9144

Systems Operation Section

Illustration 34

g03320982

Typical example

(1) Aftertreatment Regeneration Device

(ARD)

(2) Diesel Oxidation Catalyst (DOC)

(3) Diesel Particulate Filter (DPF)

The CEM for the engine consists of the following

components.

If applicable, a flexible exhaust pipe can connect the

engine to the Clean Emissions Module (CEM). Refer

to Disassembly and Assembly for the correct

procedure to install the flexible exhaust pipe.

• Aftertreatment Regeneration Device (ARD)

• Diesel Oxidation Catalyst (DOC)

• Diesel Particulate Filter (DPF)

The solid particulate matter that is collected by the

DPF consists of soot (carbon) from incomplete

combustion of the fuel and inorganic ash from the

combustion of any oil in the cylinder.

The Diesel Oxidation Catalyst (DOC) oxidizes the

carbon monoxide and the hydrocarbons that are not

burnt in the exhaust gas into carbon dioxide and

water. This is a through flow device that will continue

to operate during all normal engine operating

conditions.

The rate of accumulation of ash is slow. The filter is

designed to contain all the ash that is produced until

the defined service interval. Refer to Operation and

Maintenance Manual for more information.

The soot that is collected must be removed at regular

intervals by a process of regeneration.

The wall flow Diesel Particulate Filter (DPF) collects

all solid particulate matter in the exhaust gas.

The wall flow DPF continuously regenerates at

modest temperatures, using passive regeneration to

continually control soot loading.

The Aftertreatment Regeneration Device (ARD)

increases the exhaust gas temperature to a sufficient

level. The soot that is collected in the DPF is

oxidized.

Active regeneration occurs when the engine does not

create enough heat in order to regenerate the DPF.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR9144

39

Systems Operation Section

Air is supplied to the ARD through pressurized air

from the turbocharger and air pump. Fuel is supplied

from the leakoff line to the ARD.

Limited speed strategy – The limited speed strategy

will be activated after the soot level has reached 100

percent. At this time, the engine will automatically

drop to the programmed speed of 1800 rpm with 50

percent engine load. The only method to unlock the

limited speed is to perform a regeneration.

Fuel is injected onto a wire gauze by the first injector.

The fuel is ignited by the glow plug. The ARD is air

cooled.

Forced engine shutdown strategy – The forced

engine shutdown strategy will be activated when the

soot level reaches 140 percent soot level. The engine

will operate between 800 and 1800 rpm. After 30

seconds, the engine will automatically shut down.

The engine can be restarted but will only operate for

30 seconds before shutting down again.

The combustion of the fuel generates heat. Once the

temperature recorded by the inlet temperature sensor

has reached 300° C (572° F), the second injector will

inject fuel into the exhaust gas stream. The fuel from

the second injector ignites when the fuel comes into

contact with the face of the DOC due to the heat

created by first injection event.

Force Switch Regeneration – Regeneration initiated

by the force switch is allowed at all times.

The DOC oxidizes the soot into carbon dioxide, which

then passes through the filter and into the

atmosphere.

Passive Regeneration – Passive regeneration is

allowed at all times.

The ARD may automatically switch ON and OFF. The

ARD may be manually controlled by the operator. The

ARD is controlled by the sensor for the soot level. The

sensor for the level of soot will ensure that the level of

soot in the filter is kept within limits. This is referred to

as a regeneration of the filter.

Active Regeneration – Active regeneration will be

allowed once soot level is greater than 60 percent.

Regeneration Types and Operating

Criteria

In order to regenerate the DPF at the right time, the

engine ECM must know how much soot is in the DPF.

Measurement of soot is accomplished through the

following means:

Regenerations

There are two types of regeneration. These

regenerations are referred to as passive regeneration

and active regeneration.

• Delta pressure measurement across the DPF

• Calculated model based on developed engine out

soot measurements

Passive Regeneration

The soot level may be displayed as a graphical bar,

or as an actual percentage. Soot level can also be

viewed through the electronic service tool.

Passive regeneration occurs when the engine is

operating and the exhaust temperatures reach

sufficient levels.

The frequency of regeneration will depend on the

operating conditions of the engine. The frequency of

regeneration will depend on the ambient conditions of

the operation of the engine. Regeneration will be

most frequent if the application operates with a high

transient content or the atmospheric temperature or

the altitude is high.

Active Regeneration

Active regeneration occurs when the soot load in the

DPF reaches 60 percent. The ARD must be used to

create the heat necessary to regenerate the DPF.

The ARD may perform an active regeneration while

the engine is at any operating condition.

Soot Level Outputs

Active regenerations consume more fuel and take a

shorter time to complete compared to passive

regenerations. This longer time is due to maintaining

lower desired DPF inlet temperatures to avoid

damaging the DPF from extreme changes in

temperature.

The soot level percentage that is generated by the

engine ECM is used in determining:

• When to activate the DPF lamp

• When to activate the DPF and flashing warning

lamp (for high soot load events)

Active regeneration has one distinct operating region.

The operating region is determined by the soot level.

The region is between 60 and 140 percent soot level.

The parameters listed below outline the operating

criteria that are monitored to activate and sustain

active regeneration.

• When to activate the forced engine shutdown

strategy

DPF Lamp – The DPF lamp will be illuminated at a

80 percent soot level on engines.

Note: All of the parameters listed below are

independently developed for each application. All

applications may not meet the exact criteria outlined

below.

DPF and Flashing Warning Lamp – The action lamp

will be illuminated at a 100 percent soot level for

engines. The DPF lamp will remain on with the action

lamp.

This document is printed from SPI². Not for RESALE

![]()

40

KENR9144

Systems Operation Section

Regeneration switch – The disable regeneration

switch is not enabled.

Sensors

Differential Pressure Sensor (DPF ) – This sensor

measures the difference in pressure of the gases as

the gases pass through the DPF.

Engine Coolant Temperature – The engine coolant

temperature should be above 70° C (158° F)

Engine Load Factor – The engine load factor should

be between 0 percent and 80 percent.

Inlet Temperature Sensor – This sensor determines

the temperature of the air that is entering the DOC

and the DPF.

DPF Outlet Temperature – The DPF outlet

temperature should be above 100° C (212° F).

Outlet Temperature Sensor – This sensor

determines the temperature of the air that is exiting

the DPF.

Manual Regenerations

Temperature Sensor – This sensor measures the

temperature within the ARD.

Manual regeneration is accomplished by pressing the

force regeneration switch. Refer to the Operation and

Maintenance Manual for correct location of switch.

Glow Plug

Fuel System for the Clean

Emissions Module

The orifice for the fuel creates a high amount of

atomization of the fuel for ignition and operation.